Rubber modifier, rubber material, preparation method and application

A rubber modifier and rubber material technology, applied in the field of material manufacturing, can solve the problems of small surface tension and difficult rubber materials, and achieve the effects of low manufacturing cost, long service life, and simple and convenient modification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

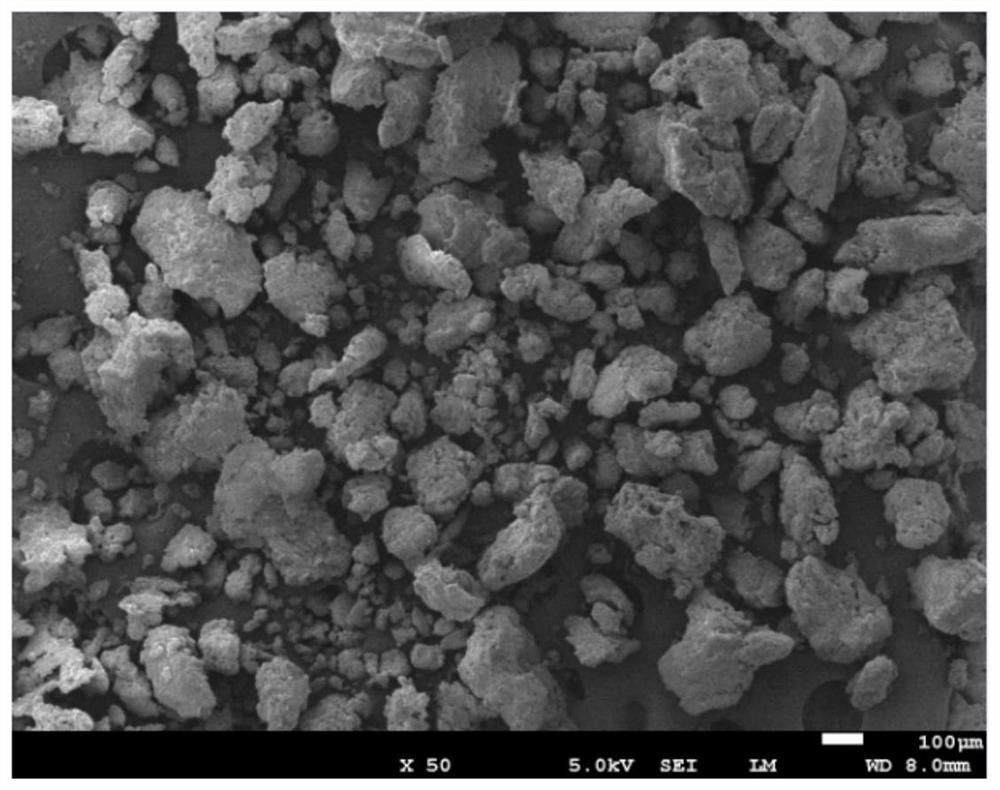

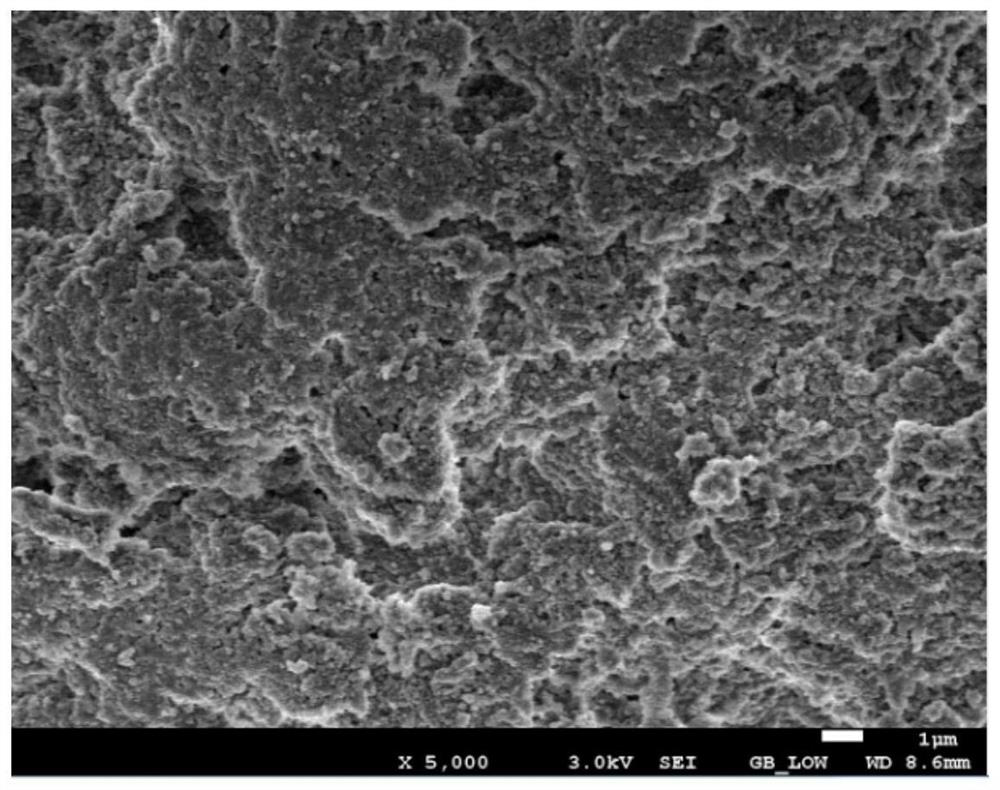

[0029] The preparation method of the rubber modifier of the present invention is that micron-scale graphite (GP) is coated and modified with cetyltrimethylammonium bromide (CTBA), and nano-scale polytetrafluoroethylene spherical microspheres ( PTFE) into sodium naphthalene solution for surface modification. The surface-modified PTFE is added into the graphite and CTAB solution for stirring treatment to obtain a granular graphite-polytetrafluoroethylene modifier H-PTFE-GP with excellent dispersibility.

[0030] After the graphite is coated and modified by CTAB, the surface roughness of graphite is increased, the surface energy is reduced, and the degree of aggregation is reduced, so that its dispersion in rubber is improved and the mutual contact between graphite is enhanced. The surface tension of polytetrafluoroethylene is the smallest, so it is difficult to be directly used in rubber materials. It needs to be treated with sodium naphthalene on the surface to increase the sur...

Embodiment 1

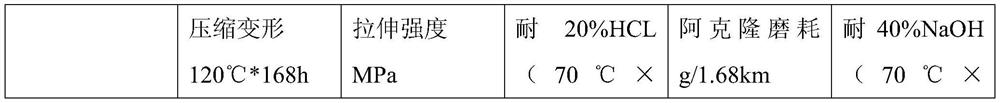

[0042] Take 10 g of graphite, place it and 2 g of cetyltrimethylammonium bromide (abbreviated as CTAB) in a beaker, add a certain amount of distilled water to fully dissolve, and stir mechanically. Take 10g of nano-polytetrafluoroethylene microspheres and mechanically stir them in sodium naphthalene solution for 20 minutes, then wash them repeatedly with clean water for 3 times, and dry them in an oven at 90°C for 1 hour. Then add the dried polytetrafluoroethylene into the mixed solution of graphite and CTAB and disperse for 4 hours under the condition of mechanical stirring at 200r / m, filter the reaction solution, wash it with absolute ethanol, and place it in a vacuum at 60°C 24h in a dry box to constant weight. Plasticize natural rubber (NR) on a double-roller mill, and vulcanize according to the following formula for rubber products to make rubber gaskets: 100 parts of NR, 30 parts of modifier H-PTFE-GP, and 2 parts of sulfur , 3 parts of accelerator, 3 parts of stearic a...

Embodiment 2

[0045] Take 10g of graphite, place it and 1g of CTAB for short in a beaker, add a certain amount of distilled water to fully dissolve, and stir mechanically. Take 12g of nano-polytetrafluoroethylene microspheres and mechanically stir them in sodium naphthalene solution for 20 minutes, then wash them repeatedly with clean water for 3 times, and dry them in an oven at 90°C for 1 hour. Then add the dried polytetrafluoroethylene into the mixed solution of graphite and CTAB and disperse for 4 hours under the condition of mechanical stirring at 200r / m, filter the reaction solution, wash it with absolute ethanol, and place it in a vacuum at 60°C 24h in a dry box to constant weight. Plasticize NR on a double-roll mill, and vulcanize according to the following formula for rubber products to make rubber gaskets: 100 parts of NR, 30 parts of modifier H-PTFE-GP, 2 parts of sulfur, accelerator 3 parts, stearic acid 3 parts, antioxidant 4 parts, activator 2 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com