Polishing device capable of protecting materials for die machining

A mold processing and polishing device technology, which is applied in the direction of grinding/polishing safety devices, grinding drive devices, metal processing equipment, etc., can solve the problems of poor material fixing effect and human injury, so as to reduce debris splashing and improve Safety and stability improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

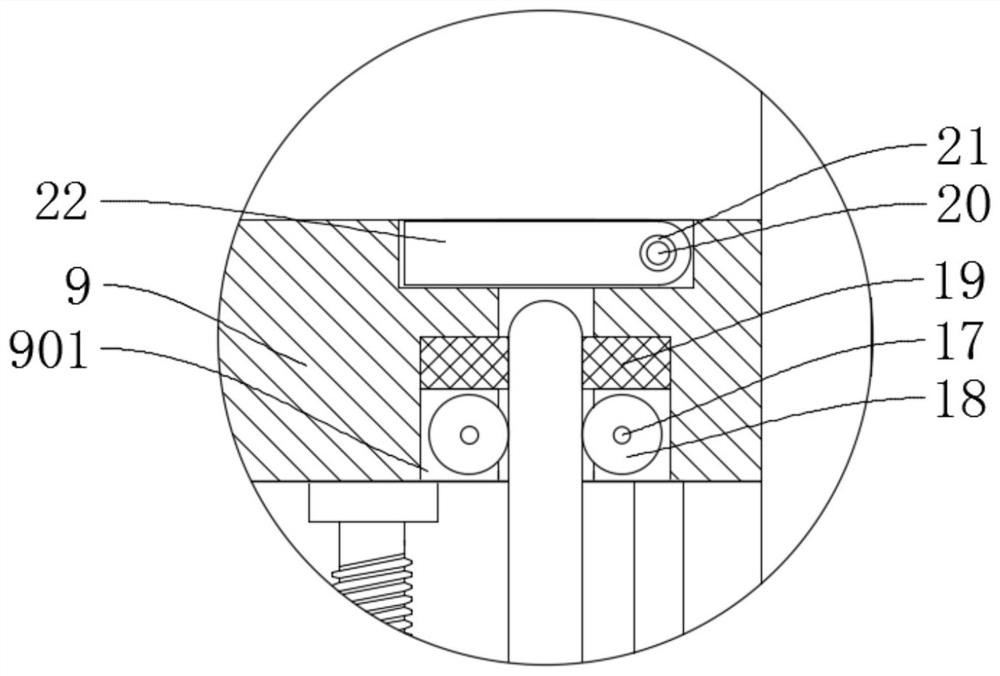

[0032] refer to figure 1 , image 3 , Figure 5 , Image 6 , Figure 7, a polishing device capable of material protection for mold processing, comprising a base 1, a polished piece 8 and a polishing mechanism, the base 1 is fixedly connected with a support seat 9, and the support seat 9 is fixedly connected with a driving mechanism, and the base 1 rotates Connecting rod 4 and the second threaded rod 10 are connected, the connecting rod 4 and the second threaded rod 10 are connected in rotation with the driving mechanism, the connecting rod 4 is connected with the first threaded rod 5 in rotation, and the first threaded rod 5 is threadedly connected with the rotating sleeve 15, the rotating sleeve 15 is fixedly connected with a jacket 16, the jacket 16 is fixedly connected with a protective glass plate 6, the protective glass plate 6 is slidably connected with the support seat 9, and the second threaded rod 10 is threaded with a threaded sleeve 11, A moving rod 12 is fixedl...

Embodiment 2

[0044] refer to figure 1 , figure 2 , a polishing device capable of material protection for mold processing, comprising a base 1, a polished piece 8 and a polishing mechanism, the base 1 is fixedly connected with a support seat 9, and the support seat 9 is fixedly connected with a driving mechanism, and the base 1 rotates Connecting rod 4 and the second threaded rod 10 are connected, the connecting rod 4 and the second threaded rod 10 are connected in rotation with the driving mechanism, the connecting rod 4 is connected with the first threaded rod 5 in rotation, and the first threaded rod 5 is threadedly connected with the rotating sleeve 15, the rotating sleeve 15 is fixedly connected with a jacket 16, the jacket 16 is fixedly connected with a protective glass plate 6, the protective glass plate 6 is slidably connected with the support seat 9, and the second threaded rod 10 is threaded with a threaded sleeve 11, A moving rod 12 is fixedly connected to the threaded sleeve 1...

Embodiment 3

[0056] refer to figure 1 , Figure 4 , a polishing device capable of material protection for mold processing, comprising a base 1, a polished piece 8 and a polishing mechanism, the base 1 is fixedly connected with a support seat 9, and the support seat 9 is fixedly connected with a driving mechanism, and the base 1 rotates Connecting rod 4 and the second threaded rod 10 are connected, the connecting rod 4 and the second threaded rod 10 are connected in rotation with the driving mechanism, the connecting rod 4 is connected with the first threaded rod 5 in rotation, and the first threaded rod 5 is threadedly connected with the rotating sleeve 15, the rotating sleeve 15 is fixedly connected with a jacket 16, the jacket 16 is fixedly connected with a protective glass plate 6, the protective glass plate 6 is slidably connected with the support seat 9, and the second threaded rod 10 is threaded with a threaded sleeve 11, A moving rod 12 is fixedly connected to the threaded sleeve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com