Chemical palladium plating solution and application thereof, and chemical palladium plating method

A technology of electroless plating and tetraammonia palladium sulfate, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems of precious metal palladium waste and increase process cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

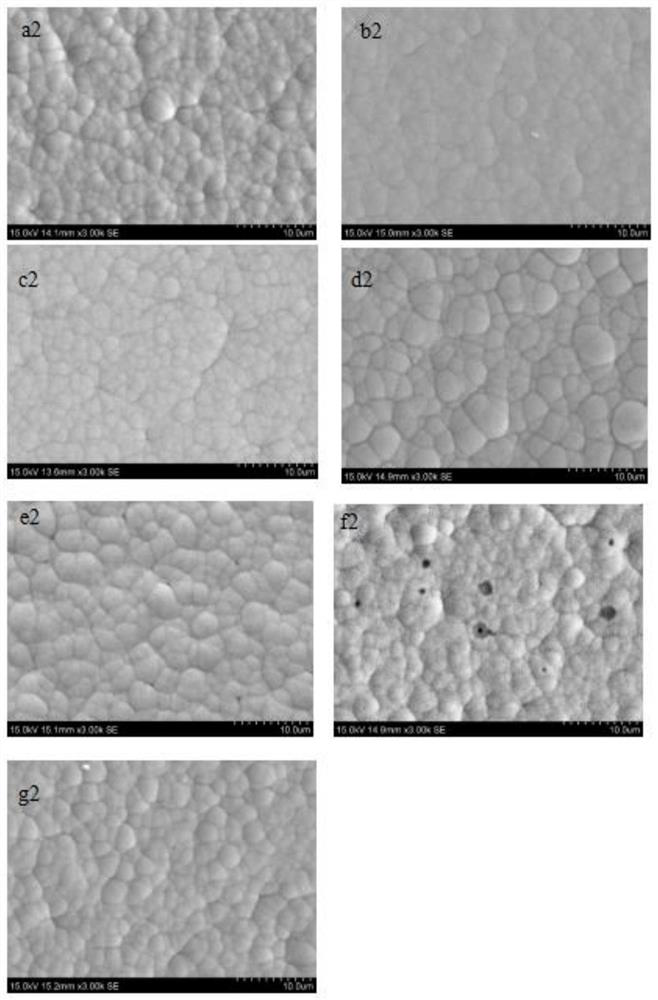

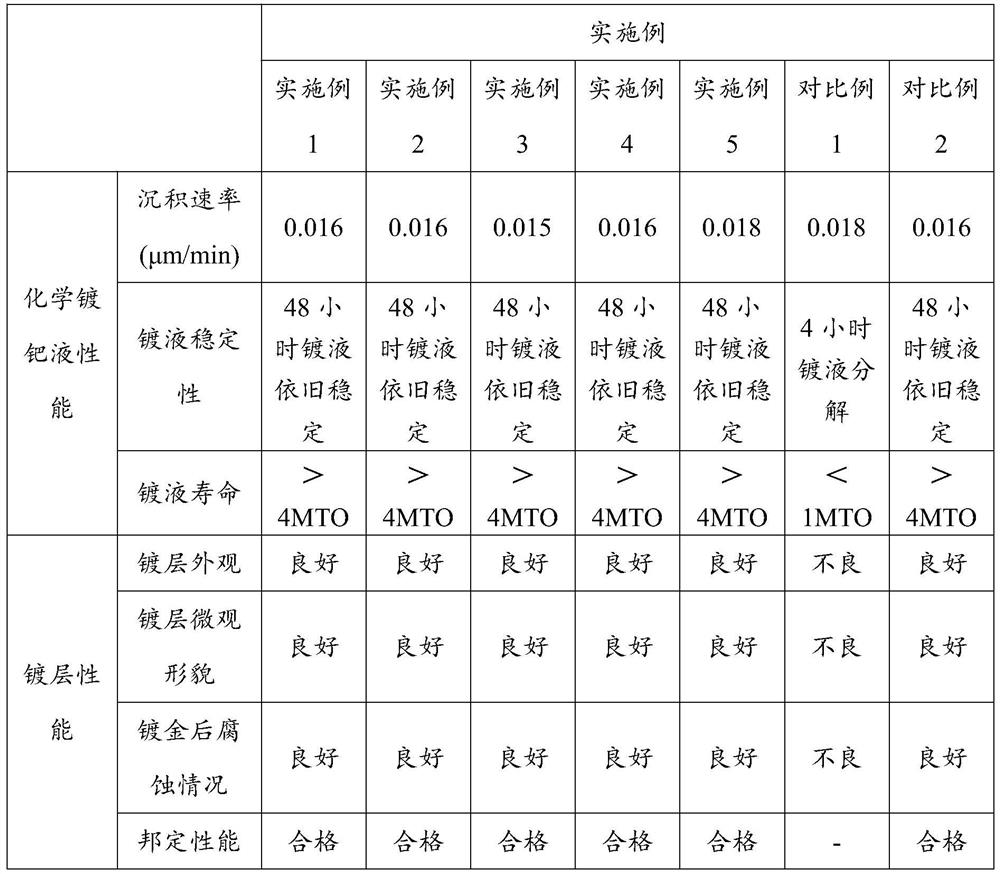

Examples

Embodiment 1

[0071] Dissolve polyethyleneimine in deionized water to obtain a concentrated solution of polyethyleneimine with a concentration of 100 mg / L;

[0072] 1g tetraammine palladium sulfate, 5g ethylenediamine, 7.5g 2-amino-n-butanol, 7.5g isobutanolamine, 10g methacrylic acid, 10g crotonic acid, 10mL polyethyleneimine with a mass concentration of 100mg / L The concentrated solution, 5g of sodium hypophosphite and 0.5L of deionized water were mixed and stirred to dissolve to obtain a primary mixed solution;

[0073] The primary mixed solution and 0.5L deionized water were mixed and stirred to dissolve to obtain an electroless palladium plating solution; the pH value of the electroless palladium plating solution was adjusted to be 7;

[0074] The printed circuit board is pretreated according to the following steps: the first pickling (100mL / LHDQ-201 acidic detergent solution, 5min) → the first water washing (deionized water, soaking for 30s) → microetching (in the mixed solution Sodiu...

Embodiment 2

[0079] Dissolve polyethyleneimine in deionized water to obtain a concentrated solution of polyethyleneimine with a concentration of 100 mg / L;

[0080] 1g tetraammine palladium sulfate, 3g ethylenediamine, 75g 2-amino-n-butanol, 10g isobutanolamine, 8g methacrylic acid, 12g crotonic acid, 50mL concentration of polyethyleneimine concentrated solution of 100mg / L, 5g of sodium hypophosphite and 0.5L of deionized water were mixed and dissolved with stirring to obtain a primary mixed solution;

[0081] The primary mixed solution and 0.5L deionized water were mixed, stirred and dissolved to obtain an electroless palladium plating solution; the pH value of the electroless palladium plating solution was adjusted to 7.

[0082] The electroless plating layer was prepared according to the method of Example 1, except that the electroless palladium plating solution prepared in Example 2 was used.

Embodiment 3

[0084] Dissolve polyethyleneimine in deionized water to obtain a concentrated solution of polyethyleneimine with a concentration of 100 mg / L;

[0085] 1g tetraammine palladium sulfate, 6g ethylenediamine, 7g 2-amino-n-butanol, 7g isobutanolamine, 8g methacrylic acid, 12g crotonic acid, 50mL concentration of polyethyleneimine concentrated solution of 100mg / L, 5g of sodium hypophosphite and 0.5L of deionized water were mixed and dissolved with stirring to obtain a primary mixed solution;

[0086] The primary mixed solution and 0.5L deionized water were mixed, stirred and dissolved to obtain an electroless palladium plating solution; the pH value of the electroless palladium plating solution was adjusted to 7.

[0087] The electroless plating layer was prepared according to the method of Example 1, except that the electroless palladium plating solution prepared in Example 3 was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com