Cleaning solution for removing water spots on surface of metallographic specimen and using method thereof

A metallographic sample and cleaning solution technology, which is applied in the preparation of test samples, non-surface active detergent compositions, inorganic non-surface active cleaning compositions, etc., can solve the problem of affecting photographic effect, low work efficiency, sample Surface rust and other problems, to achieve the effect of reducing the number of repeated preparations, easy configuration and storage, and simple steps of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A cleaning solution for removing water stains on the surface of a metallographic sample and a method of use thereof provided by the invention are composed of the following components according to the weight ratio: deionized water 100mL, anhydrous sodium carbonate 3g, EDTA (ethylenediamine Tetraacetic acid) 3g.

[0024] Configuration and cleaning steps:

[0025] (1), first add 3g of anhydrous sodium carbonate into 100mL of deionized water and stir continuously to fully dissolve, then add 3g of EDTA (ethylenediaminetetraacetic acid) powder into the sodium carbonate solution and continuously stir to fully dissolve;

[0026] (2) Immerse the sample in the solution and put it into an ultrasonic cleaning machine for cleaning for about 10 minutes;

[0027] (3) Spray absolute alcohol on the surface of the sample after ultrasonic cleaning and dry it, then metallographic observation and photography can be carried out.

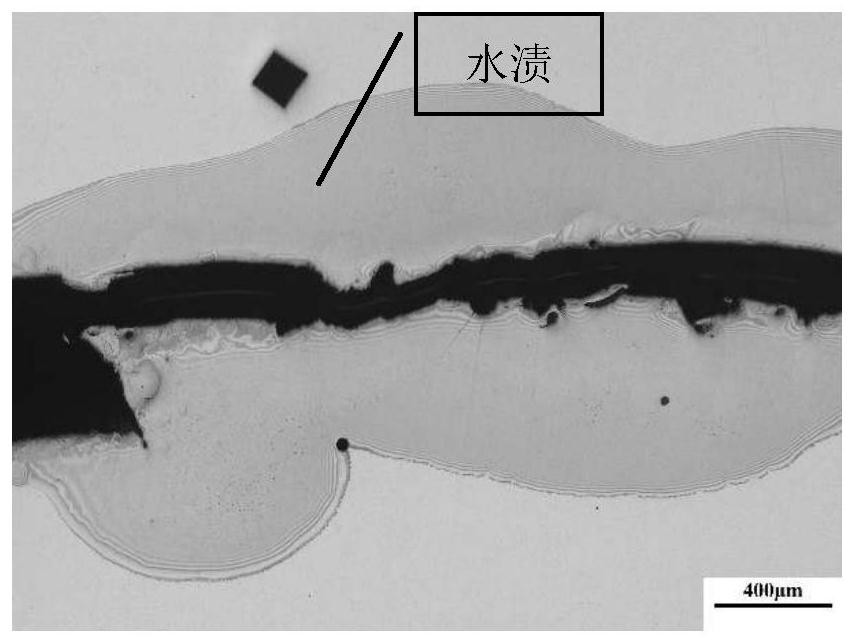

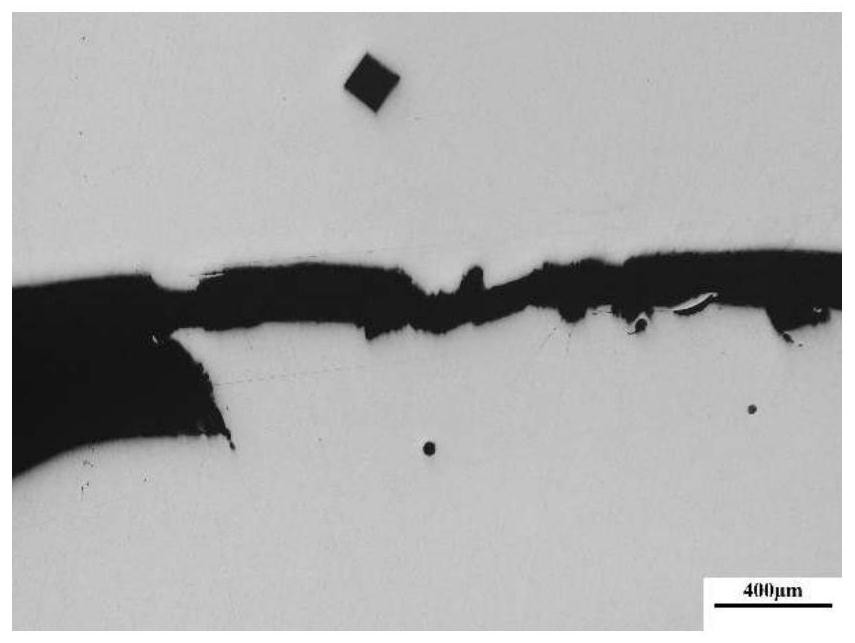

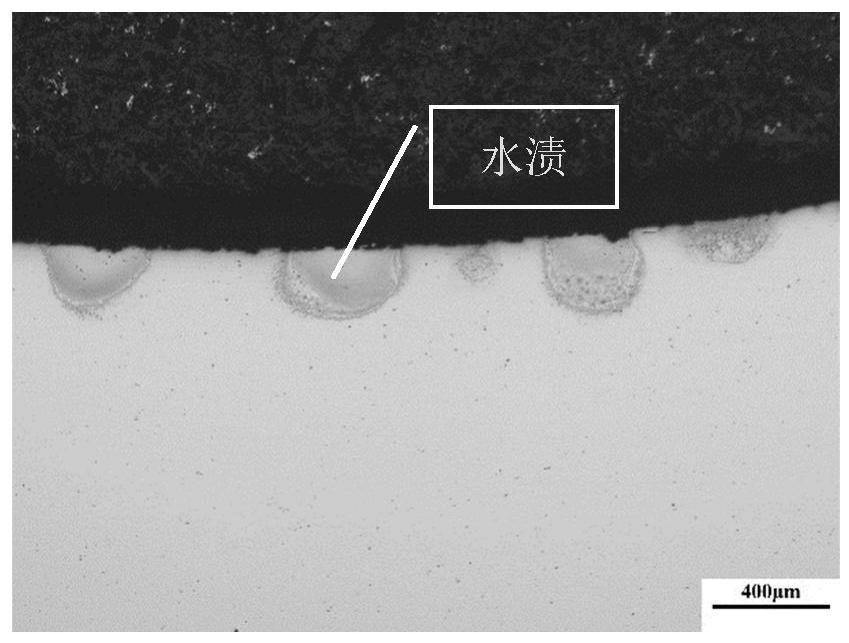

[0028] Cleaning effect: Since moisture is easy to remain in...

Embodiment 2

[0030] A cleaning solution for removing water stains on the surface of a metallographic sample and a method of use thereof provided by the invention are composed of the following components according to the weight ratio: deionized water 100mL, anhydrous sodium carbonate 6g, EDTA (ethylenediamine Tetraacetic acid) 3g.

[0031] Configuration and cleaning steps:

[0032] (1), first add 6g of anhydrous sodium carbonate into 100mL of deionized water and stir continuously to fully dissolve, then add 3g of EDTA (ethylenediaminetetraacetic acid) powder into the sodium carbonate solution and continuously stir to fully dissolve;

[0033] (2) Immerse the sample in the solution and put it into an ultrasonic cleaning machine for cleaning for about 10 minutes;

[0034] (3) Spray absolute alcohol on the surface of the sample after ultrasonic cleaning and dry it, then metallographic observation and photography can be carried out.

[0035] Cleaning effect: Since moisture is easy to remain in...

Embodiment 3

[0037] A cleaning solution for removing water stains on the surface of a metallographic sample and a method of use thereof provided by the invention are composed of the following components according to the weight ratio: deionized water 100mL, anhydrous sodium carbonate 30g, EDTA (ethylenediamine Tetraacetic acid) 30g.

[0038] Configuration and cleaning steps:

[0039] (1), first add 30g of anhydrous sodium carbonate into 100mL of deionized water and stir continuously to fully dissolve, then add 30g of EDTA (ethylenediaminetetraacetic acid) powder into the sodium carbonate solution and continuously stir to fully dissolve;

[0040] (2) Immerse the sample in the solution and put it into an ultrasonic cleaning machine for cleaning for about 10 minutes;

[0041] (3) Spray absolute alcohol on the surface of the sample after ultrasonic cleaning and dry it, then metallographic observation and photography can be carried out.

[0042] Cleaning effect: Since moisture is easy to remai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com