Coating device for mold release agent

A technology of release agent and applicator, which is applied in the direction of coating, mold shell treatment, chemical instruments and methods, etc. It can solve the problems of increased work intensity, poor structure and functionality, and difficulties in garbage and sundries, so as to prevent the flow of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

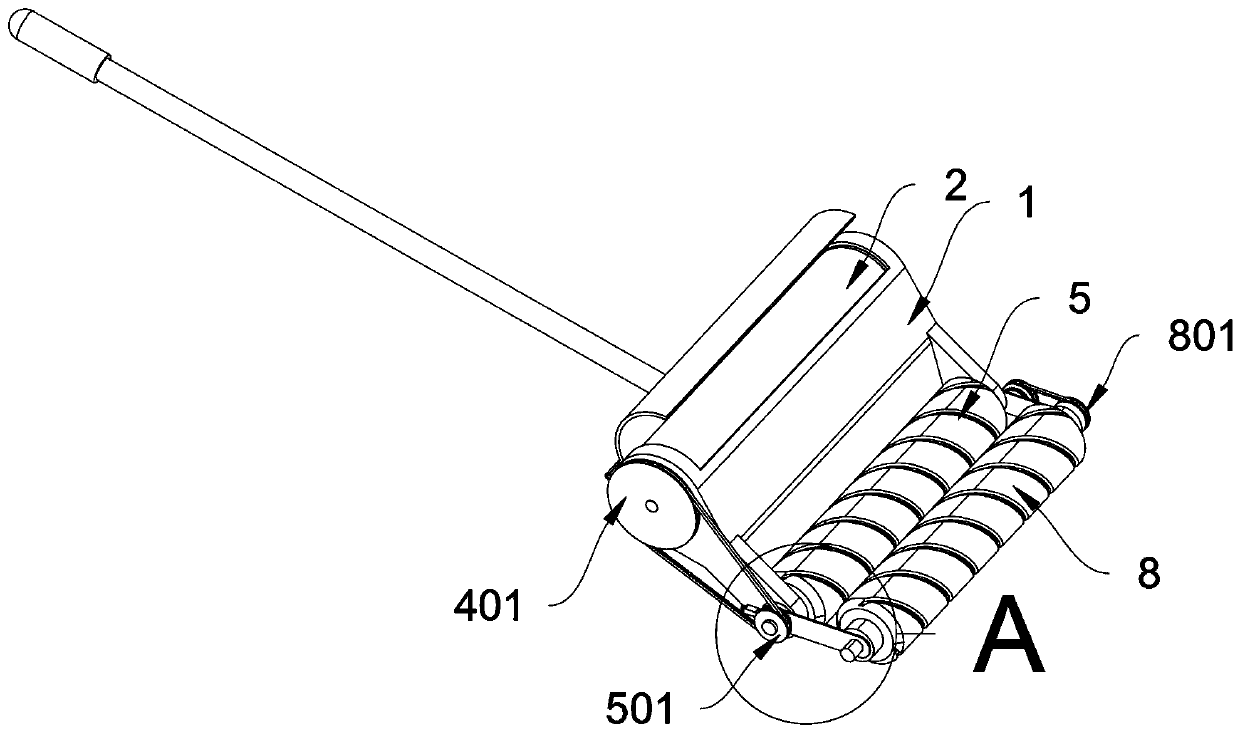

[0037] as attached figure 1 to attach Figure 9 Shown:

[0038] The present invention provides a release agent applicator, comprising a main body seat 1 and a painting roller 5; the painting roller 5 is rotatably connected to the main body seat 1, and a material storage barrel 2 is rotatably connected to the main body seat 1, and the material storage barrel 2 is welded with A positioning structure 3; a stirring shaft 4 is rotatably connected to the main body seat 1 and the storage tank 2, and stirring teeth are welded on the stirring shaft 4; and a cleaning structure 6 is arranged on the rotating shaft of the painting roller 5; refer to for example Figure 8 , the painting roller 5 includes a pulley B501 and a gear A502, a gear A502 is fixedly connected to the right side of the painting roller 5, and a pulley B501 is fixedly connected to the left side of the rotating shaft of the painting roller 5, and the pulley B501 and the pulley A401 are connected through a belt connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com