Alkyl-polyethoxy-sodium naphthalene sulfonate foam oil-displacing agent and preparation method thereof

A foam flooding, polyethoxylate technology, applied in chemical instruments and methods, reagents, drilling compositions, etc., can solve the problems of short foam half-life, difficulty in stabilizing foam at high temperature, restricting the practical application of foam flooding, etc. The effect of improving stability, improving oil resistance and excellent foam stabilization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

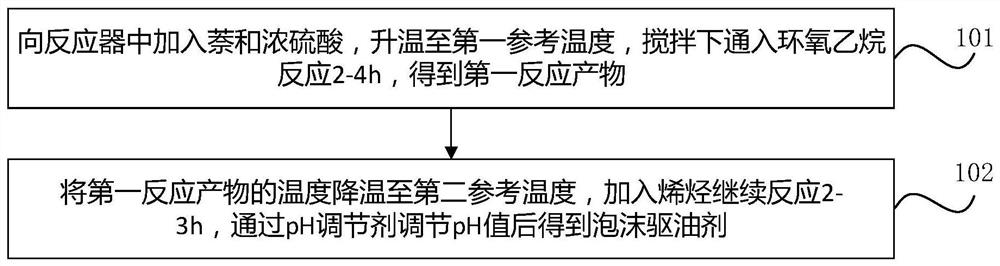

[0055] On the one hand, a kind of alkyl-polyethoxy-naphthalene sulfonate sodium foam oil displacement agent preparation method is provided, see figure 1 , the method includes:

[0056] Step 101, adding naphthalene and concentrated sulfuric acid into the reactor, raising the temperature to the first reference temperature, adding ethylene oxide under stirring, and reacting for 2-4 hours to obtain the first reaction product.

[0057] Step 102: Lower the temperature of the first reaction product to the second reference temperature, the first reference temperature is higher than the second reference temperature, add olefin to continue the reaction for 2-3 hours, adjust the pH value with a pH regulator to obtain the alkyl-polyethylene Sodium oxy-naphthalenesulfonate foaming agent.

[0058] The foam oil displacement agent provided by the embodiments of the present application has at least the following technical effects:

[0059] In the foam oil displacement agent provided in the e...

Embodiment 1

[0100] Add 50g of naphthalene and 45g of concentrated sulfuric acid into the reactor, raise the temperature to 160°C, add 240g of ethylene oxide and stir for 3h, cool down to 110°C, slowly add 60g of 1-dodecene, continue the reaction for 3h, cool down to 25°C, add hydrogen oxide Sodium adjusts the pH value to 7 to obtain a foam oil displacement agent.

Embodiment 2

[0102] Add 50g of naphthalene and 60g of concentrated sulfuric acid into the reactor, raise the temperature to 170°C, add 300g of ethylene oxide and stir for 3h, cool down to 120°C, slowly add 75g of 1-dodecene, continue the reaction for 3h, cool down to 10°C, add hydrogen oxide Sodium adjusts the pH value to 7 to obtain a foam oil displacement agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com