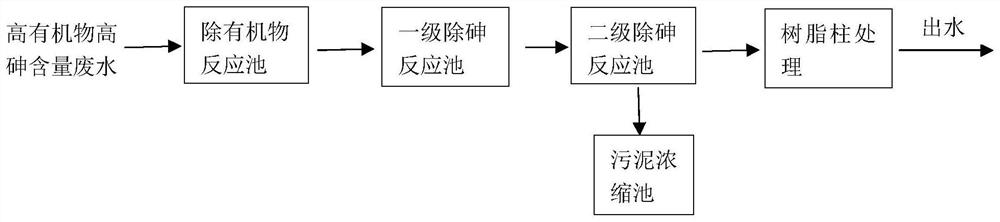

Treatment method of industrial wastewater with high organic matter content and high arsenic content

A treatment method and technology for industrial wastewater, applied in water/sewage treatment, adsorption water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of limiting organic matter removal efficiency, unfavorable microbial growth, and inability to use biochemical methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

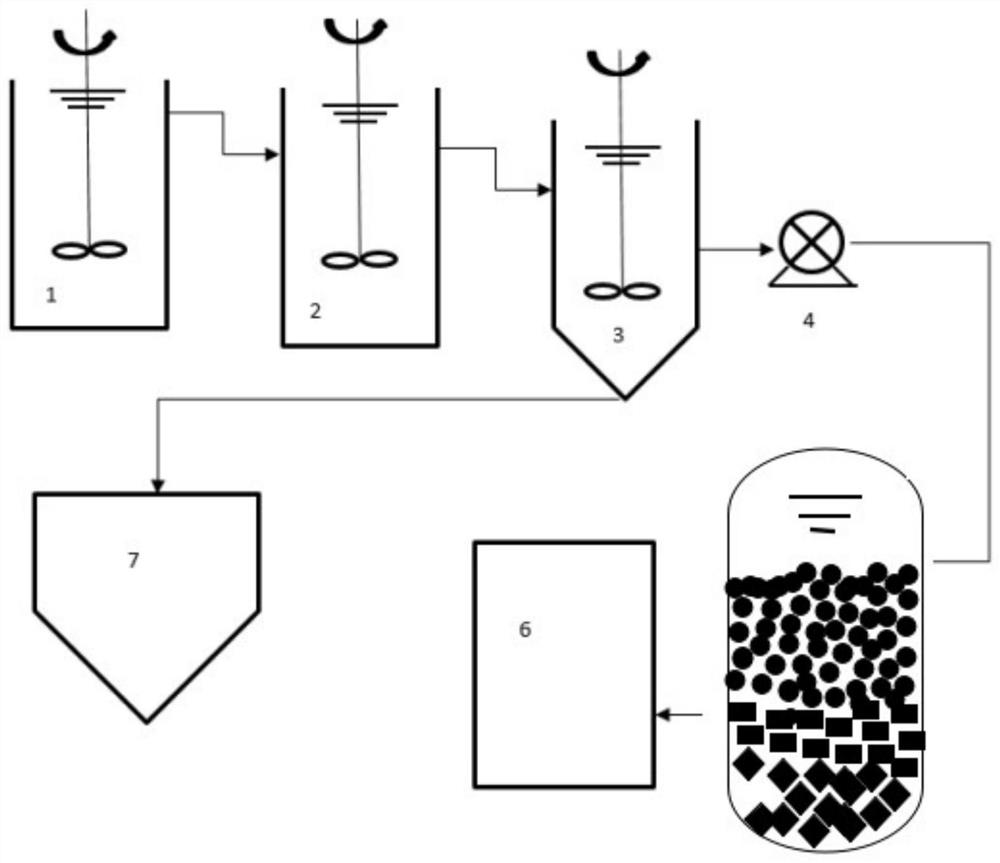

[0061] This embodiment provides a treatment method for photovoltaic semiconductor industrial wastewater with high organic matter and high arsenic content, specifically as follows:

[0062] (1) pH adjustment: import 5L of industrial wastewater into the oxidation treatment organic matter reaction tank, add hydrochloric acid to adjust the pH of the industrial wastewater to 4;

[0063] (2) Oxidation treatment to remove organic matter: add ferrous sulfate to its final concentration of 1.6mol / L, stir for 7min, add hydrogen peroxide to its final concentration of 4mol / L, stir for 30min, and oxidize the precipitation of wastewater after treatment and supernatant separation;

[0064] (3) First-level precipitation to remove arsenic: the waste water supernatant obtained in step (2) is introduced into the first-level arsenic removal coagulation sedimentation tank, and the gas-water volume ratio is 3:1. Ferric chloride until its final concentration in the wastewater treatment system is 1mo...

Embodiment 2

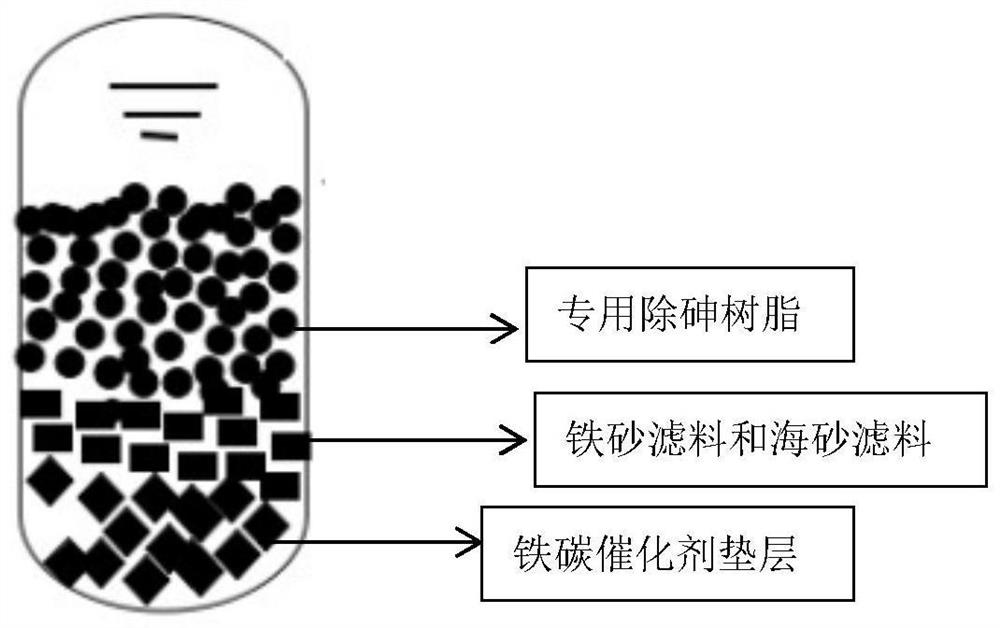

[0069] This embodiment provides a treatment method for photovoltaic semiconductor industrial wastewater with high organic matter and high arsenic content. The difference from Example 1 is that the resin columns used in step (5) are different: the resin columns used include iron carbon from bottom to top. Catalyst particle layer, iron sand filter material, sea sand filter material, special arsenic removal resin layer; the thickness of iron-carbon catalyst particle layer, iron sand filter material, sea sand filter material, and special arsenic removal resin layer is 150mm, 150mm, 250mm, 800mm .

Embodiment 3

[0071] This embodiment provides a treatment method for photovoltaic semiconductor industrial wastewater with high organic matter and high arsenic content. The difference from Example 1 is that in step (3) "add ferric chloride until its final concentration in the wastewater treatment system is 1mol / L" is replaced with "Add ferric sulfate until its final concentration in the wastewater treatment system is 4.8mol / L".

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com