Preparation method of zanthoxylum bungeanum seed oil dry powder

A technology of prickly ash seed oil and prickly ash seed, applied in the directions of edible oil/fat, fat oil/fat production, and fat production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

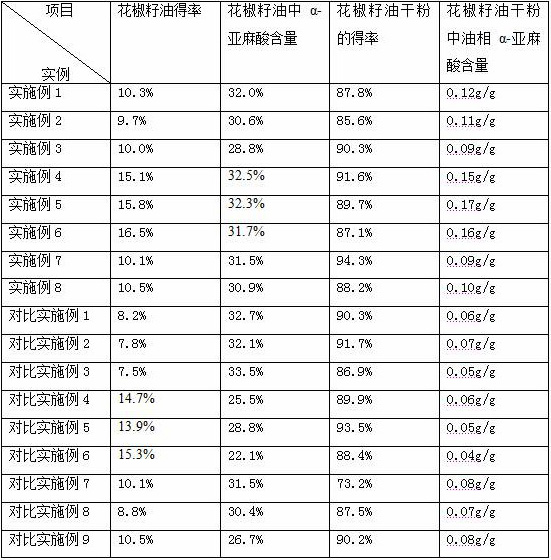

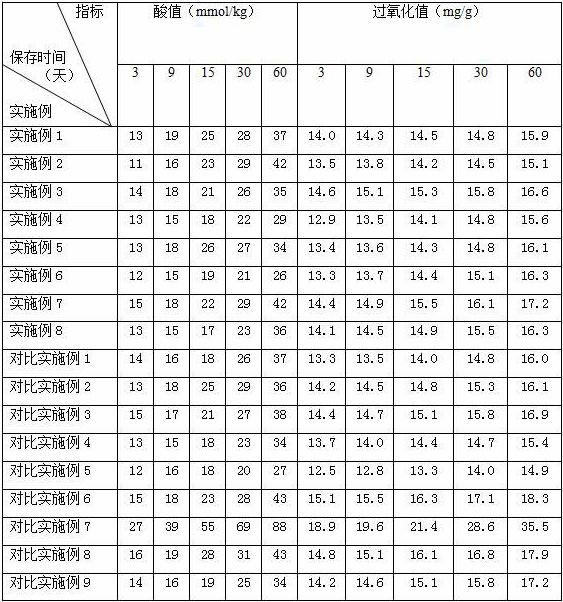

Examples

Embodiment 1

[0018] A preparation method of Zanthoxylum bungeanum oil dry powder, comprises the steps:

[0019] (1) Take 10 kg of pepper seeds with a moisture content of 15% to 20% and add them to the material tank of the electric air flow puffing machine. After heating until the temperature rises to 700°C and the pressure is 0.5Mpa, the material is extruded and discharged, and the material is added to the In the pulverizer, pulverize for 4 minutes and pass through a 20-mesh sieve to obtain the pepper seed powder;

[0020] (2) Put the Zanthoxylum bungeanum seed powder obtained in step (1) into a material bag, put it in an extraction tank, add 80kg of n-hexane of the Zanthoxylum bungeanum seed powder weight to extract for 8 minutes, after the extraction is completed, place the extraction tank at 5°C Perform rapid cooling, and after the temperature is constant, take out the material bag, place the n-hexane extract in a vacuum rotary evaporator, and treat it for 8 hours at a temperature of 72...

Embodiment 2

[0024] A preparation method of Zanthoxylum bungeanum oil dry powder, comprises the steps:

[0025] (1) Take 10 kg of pepper seeds with a moisture content of 15% to 20% and add them to the material barrel of the electric air flow puffing machine. After heating until the temperature rises to 735°C and the pressure is 0.6Mpa, the puffed seeds are extruded and the materials are added to the In the pulverizer, pulverize for 5 minutes and pass through a 30-mesh sieve to obtain the pepper seed powder;

[0026] (2) Put the Zanthoxylum bungeanum seed powder obtained in step (1) into a material bag, put it in an extraction tank, add 90kg of n-hexane of the Zanthoxylum bungeanum seed powder weight to extract for 9 minutes, after the extraction is completed, place the extraction tank at 8°C Perform rapid cooling, and after the temperature is constant, take out the material bag, place the n-hexane extract in a vacuum rotary evaporator, and treat it for 9 hours at a temperature of 72°C to 7...

Embodiment 3

[0030] A preparation method of Zanthoxylum bungeanum oil dry powder, comprises the steps:

[0031] (1) Take 10 kg of pepper seeds with a moisture content of 15% to 20% and add them to the material tank of the electrothermal airflow puffing machine. After heating until the temperature rises to 800°C and the pressure is 0.8Mpa, the puffed seeds are extruded and the materials are added to the In the pulverizer, pulverize for 6 minutes and pass through a 30-mesh sieve to obtain the pepper seed powder;

[0032] (2) Put the Zanthoxylum bungeanum seed powder obtained in step (1) into a material bag, put it in an extraction tank, add 100kg of n-hexane of the Zanthoxylum bungeanum seed powder weight to extract for 10 minutes, after the extraction is completed, place the extraction tank at 10°C Perform rapid cooling, and after the temperature is constant, take out the material bag, place the n-hexane extract in a vacuum rotary evaporator, and treat it for 10 hours at a temperature of 72...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com