Enhanced heat exchange fin

A technology to enhance heat transfer and fins, applied in heat exchange equipment, lighting and heating equipment, tubular elements, etc., can solve the problems of ineffective enhancement of heat transfer, insufficient improvement of field synergy, and increased fluid resistance, etc., to achieve improved The degree of synergy, the reduction of product cost, and the effect of enhancing heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the embodiment given with accompanying drawing.

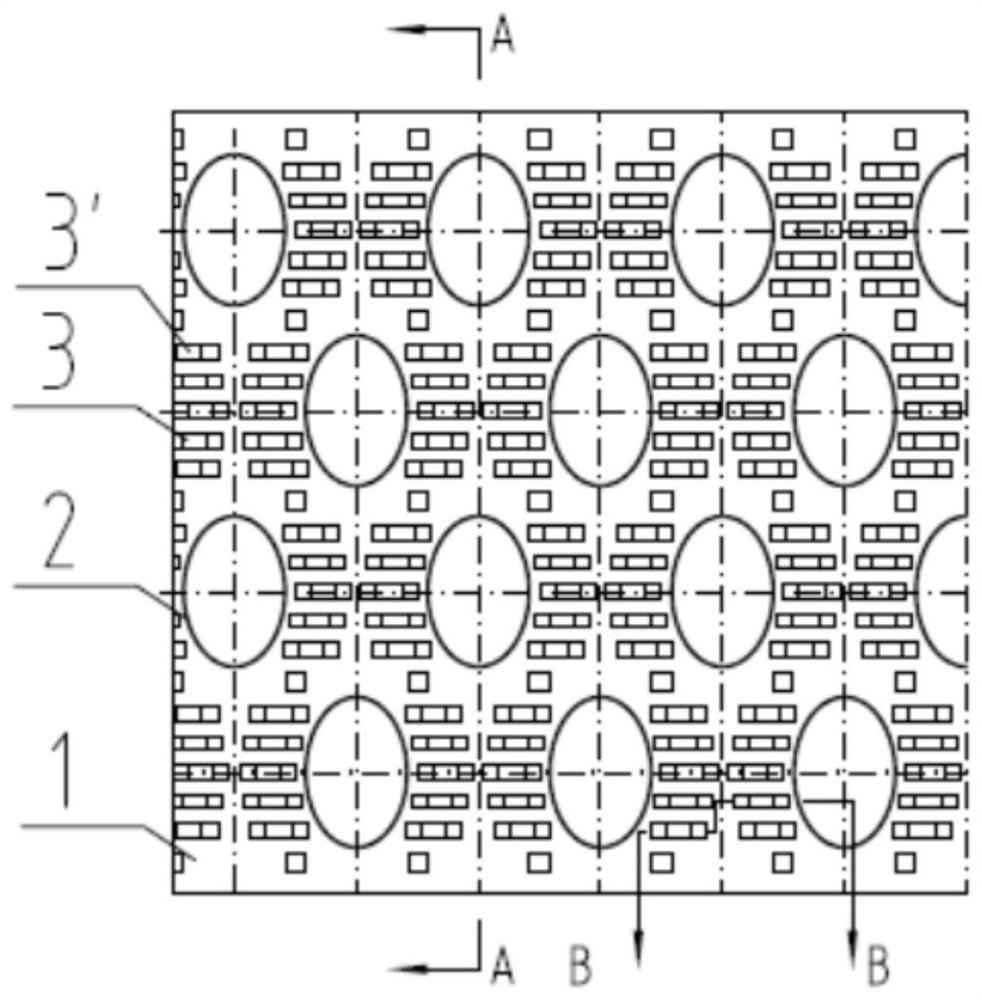

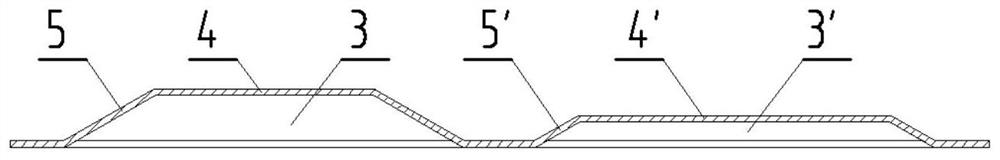

[0020] Such as Figure 1-3 As shown, the enhanced heat exchange fin of the present invention includes a fin body 1 and multiple rows of parallel heat exchange base tube penetration holes 2 opened on the fin body 1, and any two adjacent heat exchange base tubes in each row Bridge-shaped protrusions 3, 3' with different heights are opened between the piercing holes 2, and each of the bridge-shaped protrusions 3, 3' passes through two piercing holes 2 of the heat exchange base tube along the direction of air flow. Center line symmetrical arrangement. The two ends 5, 5' of the bridge-shaped protrusions 3, 3' are connected to the fin body 1, and are inclined surfaces forming an angle of less than or equal to 90 degrees with the fin body 1. The tops 4, 4' of the bridge-shaped protrusions 3, 3' are rectangular, parallel to the fin body 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com