A connection construction method of urban high-water-level and large-diameter reinforced concrete sewage pipelines

A construction method and sewage pipeline technology, which is applied in the direction of sewer pipeline system, waterway system, water supply device, etc., can solve the problems of easy damage of equipment or flushing into downstream pipelines, concrete blocks flushing downstream, and difficulty in pipeline construction, etc., so as to avoid Large-scale damage, small workload, and the effect of reducing disturbance to residents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

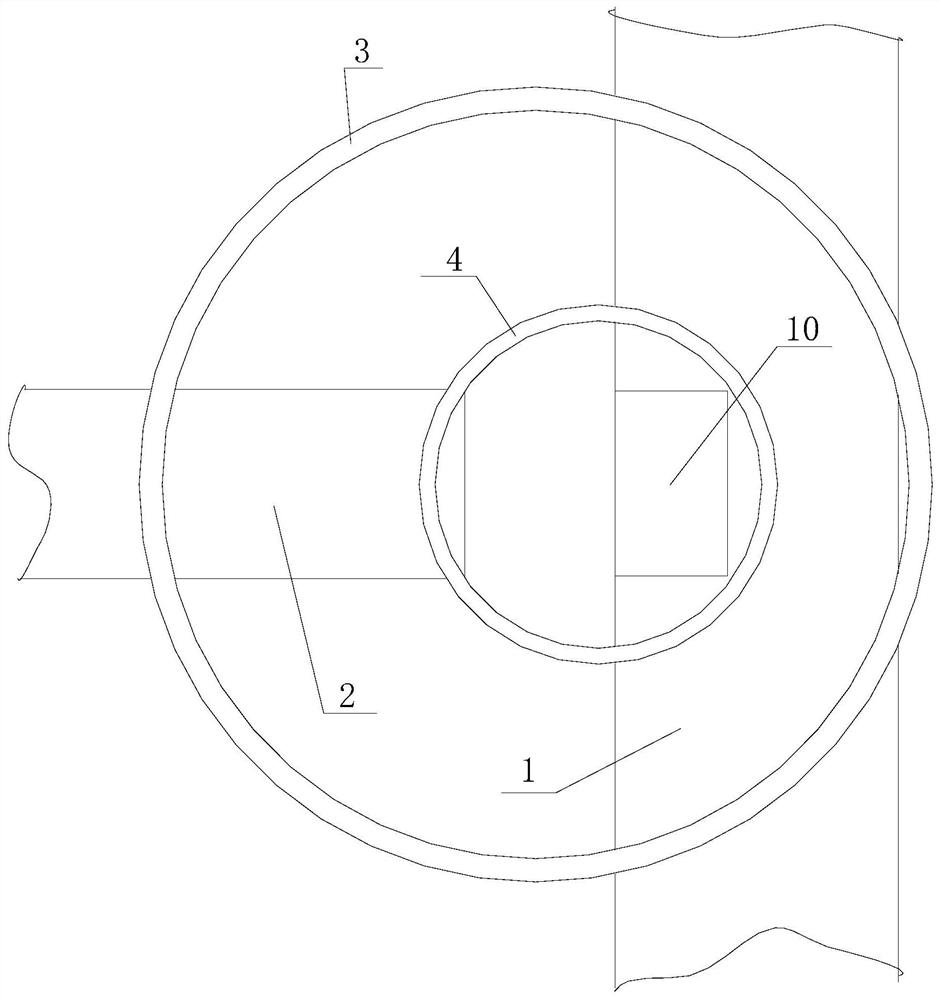

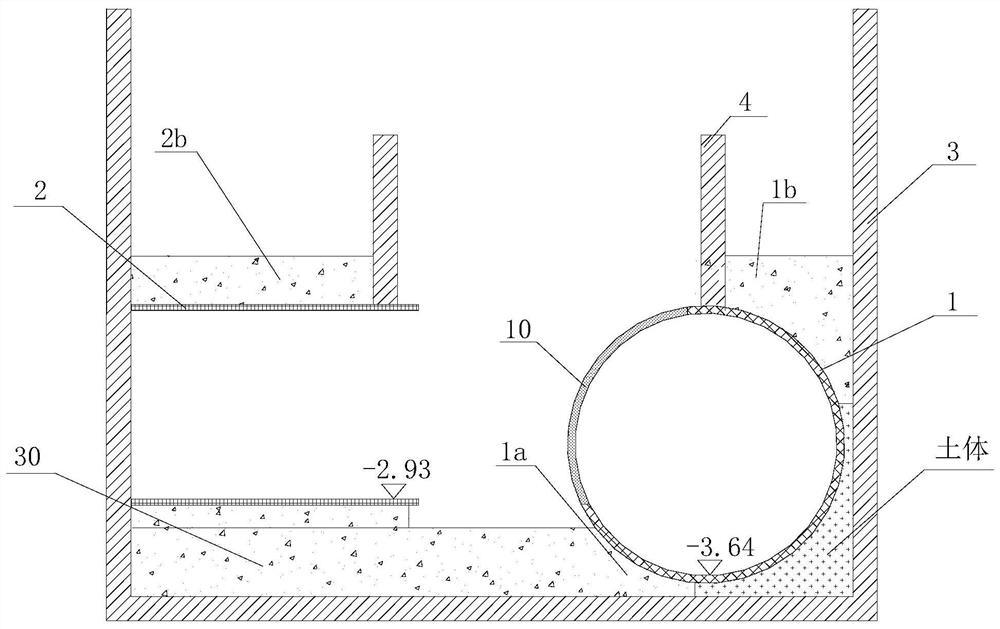

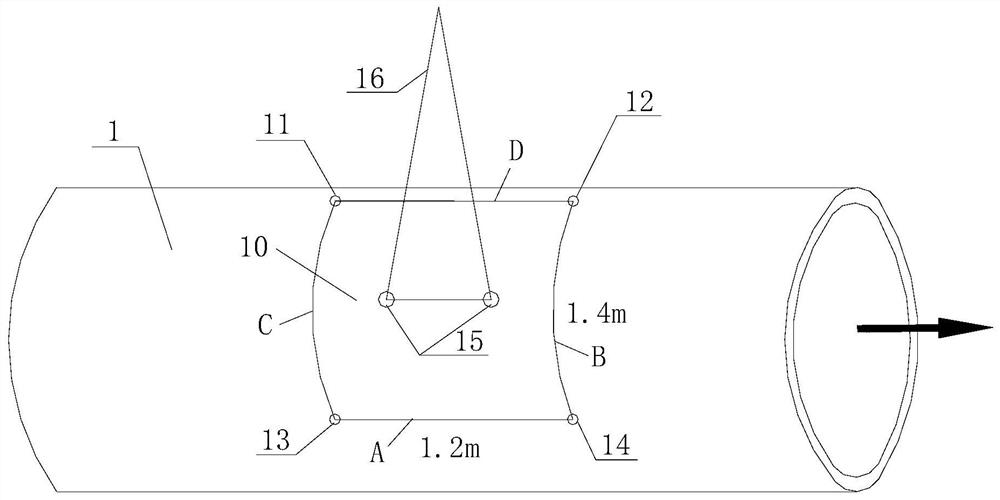

[0032] The present invention will be further described below in conjunction with accompanying drawing.

[0033] see Figure 1 to Figure 3 , the connection construction method of urban high water level large-diameter reinforced concrete sewage pipeline of the present invention, comprises the following steps:

[0034] Step 1: First build a receiving well at the connection point of the existing pipeline with a diameter of DN1800, so that the connection point of the existing pipeline is located in the receiving well 3, and the receiving well 3 also reserves a new pipe with a diameter of DN1200 on the well wall Pipeline 2 is pushed into the hole perpendicular to existing pipeline 1, so that the port of newly built pipeline 2 is pushed into receiving well 3, and the elevation of the inner bottom of newly built pipeline 2 is 0.71m higher than that of existing pipeline 1; receiving well 3 The diameter of the well is DN4100, and the receiving well 3 is built by the reverse method, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com