ti with high fracture toughness 2 Alnb-based alloy and its preparation method and application

A high-fracture, base alloy technology, applied in the field of titanium alloys, can solve problems such as the inability to meet the fracture toughness requirements of materials, and achieve the effect of low fatigue crack growth rate and high fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

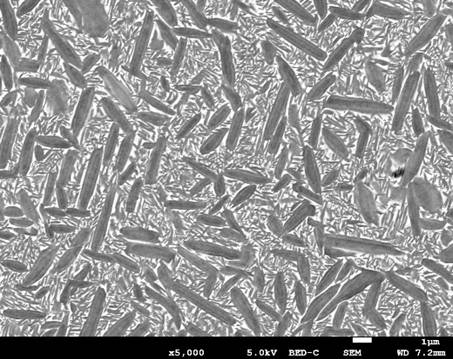

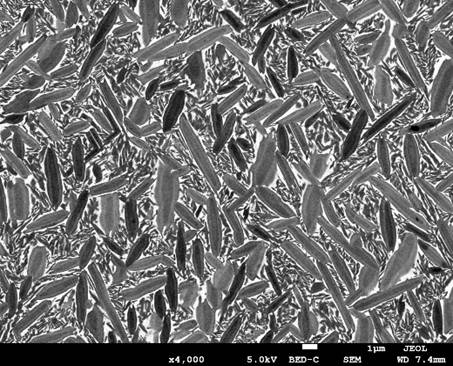

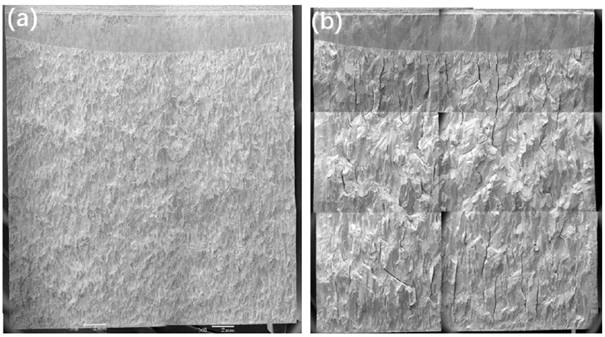

Image

Examples

preparation example Construction

[0050]The present invention also provides a high breakage toughness Ti2The preparation method of AlNB base alloy includes the following steps:

[0051]Titanium, aluminum and niobium are used as raw materials, and after proportional ingredients, smelting is obtained.

[0052]In a particular embodiment of the invention, a ingot is prepared by vacuum self-consuming + coating + self-consuming melting method. Specifically, a vacuum self-consuming melting, second vacuum coating smelting, three vacuum self-consuming melting.

[0053]As an embodiment of the present invention, the specific process is: ingredient calculation, electrode pressing, electrode blanket welding, a vacuum self-consuming melting, secondary vacuum coating, three vacuum self-consuming smelting. First, according to the nominal ingredient component, the weight of the electrode is calculated, and then the raw material mixing and electrode press is performed, and the electrode is prepared, and the electrode is obtained, and after a ...

Embodiment 1

[0066]Ti of high break2Preparation of AlNB base alloy

[0067]High breakage toughness is prepared according to the proportional ingredients listed in Table 12The AlNb base alloy, the alloy ingredient made also see Table 1.

[0068]Table 1 Different high break toughness Ti2Ingredients for AlNB bases and end components

[0069]

[0070]Specifically, the above high-grade fracture toughness Ti2The preparation method of AlNb bases includes the following steps:

[0071]The spindle is prepared by vacuum self-consuming + coating + self-consuming melting method by vacuum self-consuming + coated melting method. The specific process is: ingredient calculation, electrode pressing, electrode blanket welding, a vacuum self-consuming melting, second vacuum coating, three vacuum self-consuming smelting. The raw materials required for ingots include: sponge titanium, high-purity aluminum peas, pure NB crumbs. First, according to the nominal ingredient component, the weight of the electrode is calculated, and then ...

Embodiment 2

[0073]Ti of high break2Preparation of AlNB base alloy

[0074]High breakage toughness is prepared according to the raw material and treatment method listed in Table 2.2AlNB base alloy parts.

[0075]Table 2 Different high break toughness Ti2Raw materials and treatment methods of AlNB base alloy

[0076]

[0077]Specifically, the above high-grade fracture toughness Ti2The preparation method of AlNb base alloy includes the following steps:

[0078]The φ180 mm finished ingot made in Example 1 was removed by the car cut into the surface of the skin, and the diameter of the surface of the surface was φ170 mmm; then the Ti was obtained by repeated upsetting.2The AlNB alloy rod, which results in a respective small tray after forging, and is obtained by the above solid-dissolving heat treatment and a time-heating heat treatment to obtain a respective tray.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com