Culture method for improving grease content of saccharomyces cerevisiae by maintaining ultralow-concentration organic carbon source and application of culture method

A culture method and technology of Saccharomyces cerevisiae, applied in the biological field, can solve problems such as safety disputes, difficulty in commercial application, and no significant increase in oil production, and achieve the effect of promoting oil accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Under the conditions of different organic carbon source concentrations, the growth and oil content of Saccharomyces cerevisiae were measured, and the specific implementation steps were as follows:

[0057] Using glucose as the organic carbon source, Saccharomyces cerevisiae was cultivated by continuous flow feeding. During the cultivation process, the concentration of glucose in the culture solution was measured in real time with a biosensor, and the flow velocity of the glucose mother solution was adjusted to make the concentration of glucose in the culture solution Maintain at 0.1g / L, 0.5g / L, 1g / L, 10g / L, 20g / L, 50g / L respectively, measure the biomass (weight method) and oil content of Saccharomyces cerevisiae in the culture medium after continuous culture for 4 days (chloroform-methanol method). Other culture conditions are: inoculum size 5%, yeast extract powder 1%, peptone 2%, temperature 28°C, rotation speed 1000rpm, air ventilation volume 5vvm, pH6. It should be...

Embodiment 2

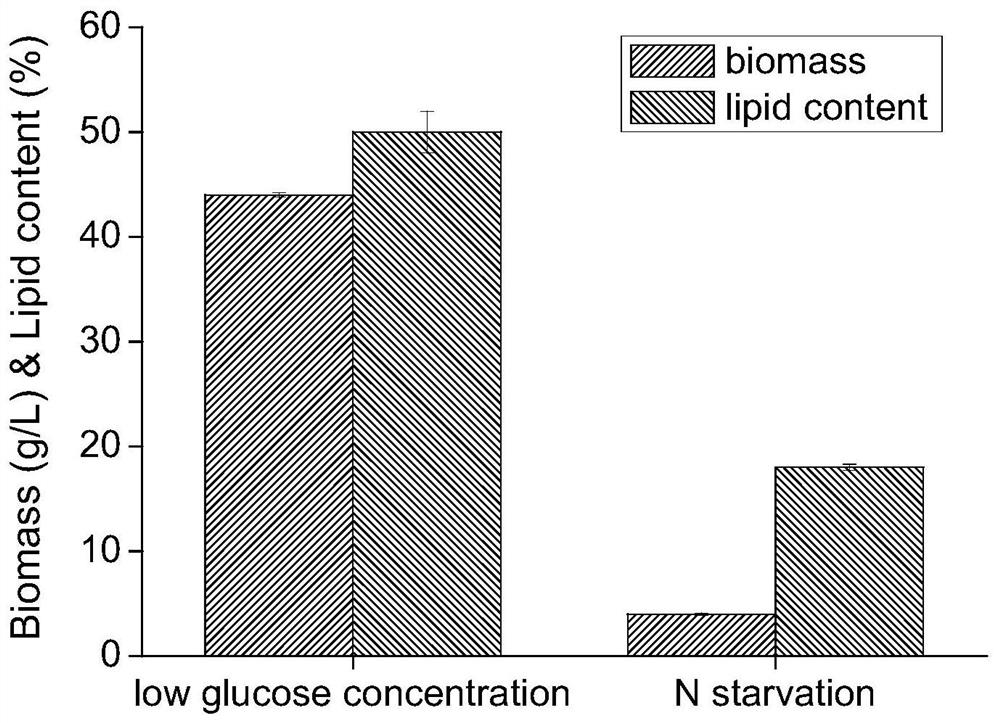

[0060] In the case of ultra-low concentration of organic carbon source and nitrogen deficiency, the comparison of the effects on the growth and oil content of Saccharomyces cerevisiae, the specific implementation steps are as follows:

[0061] Using glucose as the organic carbon source, Saccharomyces cerevisiae was cultivated by continuous flow feeding. During the cultivation process, the concentration of glucose in the culture solution was measured in real time with a biosensor, and the flow velocity of the glucose mother solution was adjusted to make the concentration of glucose in the culture solution Maintain at 0.5g / L. At the same time, taking the culture group without adding nitrogen source as a control, Saccharomyces cerevisiae was cultured by adding 150 g / L glucose once. After continuous cultivation for 4 days, the biomass (weight method) and oil content (chloroform-methanol method) of Saccharomyces cerevisiae in the culture medium were measured. Other culture conditi...

Embodiment 3

[0064] Under anaerobic and aerobic culture conditions, the effects of ultra-low concentration organic carbon sources on the growth and oil content of Saccharomyces cerevisiae were studied. The specific implementation steps are as follows:

[0065] Using glucose as the organic carbon source, Saccharomyces cerevisiae was cultured by continuous feed feeding under anaerobic and aerobic conditions respectively. During the cultivation process, a biosensor was used to measure the concentration of glucose in the culture medium in real time and adjust the concentration of the glucose mother solution. The flow rate was used to maintain the glucose concentration in the culture medium at 0.5 g / L. After continuous cultivation for 4 days, the biomass (weight method) and oil content (chloroform-methanol method) of Saccharomyces cerevisiae in the culture medium were measured. Other culture conditions are: inoculum size 5%, yeast extract powder 7%, peptone 0%, temperature 38° C., rotation spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com