Foam concrete based on high-stability foaming agent and preparation method of foam concrete

A foam concrete and high stability technology, applied in the field of concrete additives, can solve the problems of poor foaming stability of vegetable protein foaming agents, inability to realize large-scale promotion and use, and insufficient compatibility of gel materials, etc., to achieve excellent heat insulation ability, excellent thermal stability, the effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

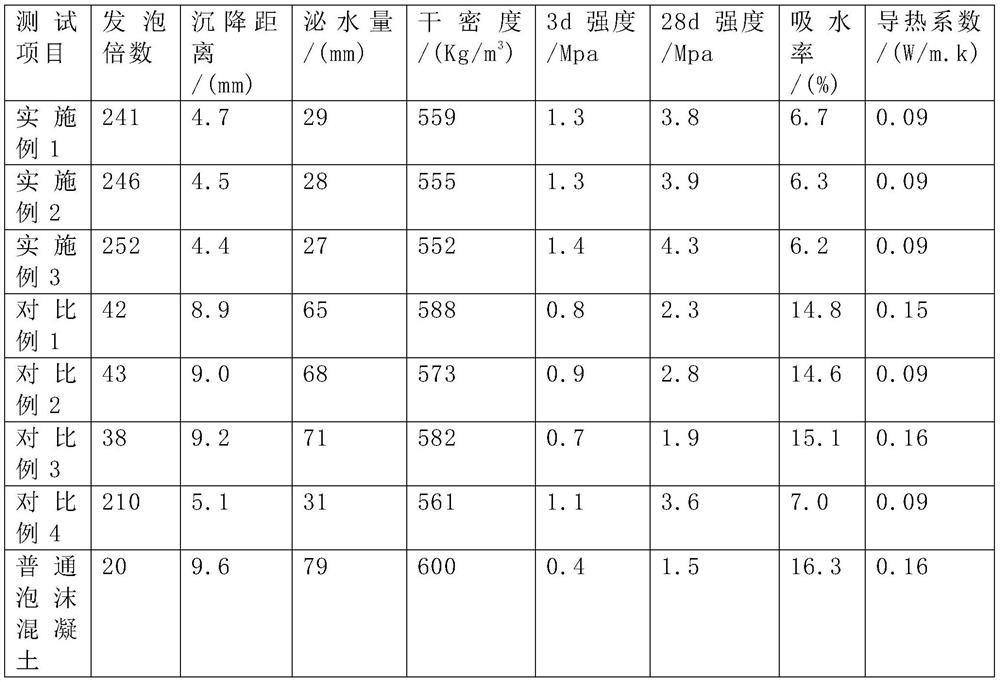

Examples

Embodiment 1

[0043] A foam concrete based on a high-stability foaming agent, the mass ratio of the modified foaming agent, cement slurry, and low-hardness tap water is 1:500:100; the modified halloysite, modified nanoparticles The mass ratio of the mixed solution and the anionic surfactant is 4:1:20.

[0044] The raw material components of the modified halloysite are as follows: in parts by weight, 60 parts of halloysite, 13 parts of sodium dodecanoate, 8 parts of cyclohexanone, 24 parts of methyl methacrylate, and 15 parts of graphene oxide , 8 parts of silane coupling agent, 8 parts of dibenzoyl peroxide, 15 parts of ferric oxide, 8 parts of hydrazine hydrate, and 22 parts of amphoteric surfactant.

[0045] The modified nanoparticle mixed liquid mainly includes modified auxiliary liquid and nanoparticles, and the mass ratio of the modified auxiliary liquid and nanoparticles is 3:1.

[0046] S1. Preparation of modified halloysite:

[0047] A. Preparation of halloysite airgel:

[0048] ...

Embodiment 2

[0059] A foam concrete based on a high-stability foaming agent, the mass ratio of the modified foaming agent, cement slurry, and low-hardness tap water is 1:500:(200); the modified halloysite, modified The mass ratio of the nanoparticle mixture solution and the anionic surfactant is 5:1:20.

[0060] The raw material components of the modified halloysite are as follows: in parts by weight, 65 parts of halloysite, 14 parts of sodium dodecanoate, 9 parts of cyclohexanone, 26 parts of methyl methacrylate, and 17 parts of graphene oxide , 11 parts of silane coupling agent, 12 parts of dibenzoyl peroxide, 20 parts of ferric oxide, 9 parts of hydrazine hydrate, and 24 parts of amphoteric surfactant.

[0061] The modified nanoparticle mixed liquid mainly includes modified auxiliary liquid and nanoparticles, and the mass ratio of the modified auxiliary liquid and nanoparticles is 4:1.

[0062] S1. Preparation of modified halloysite:

[0063] A. Preparation of halloysite airgel:

[0...

Embodiment 3

[0075] A foam concrete based on a high-stability foaming agent, the mass ratio of the modified foaming agent, cement slurry, and low-hardness tap water is 1:500:300; the modified halloysite, modified nanoparticles The mass ratio of the mixed solution and the anionic surfactant is 7:1:20.

[0076] The raw material components of the modified halloysite are as follows: in parts by weight, 70 parts of halloysite, 15 parts of sodium dodecanoate, 10 parts of cyclohexanone, 28 parts of methyl methacrylate, and 20 parts of graphene oxide , 14 parts of silane coupling agent, 14 parts of dibenzoyl peroxide, 25 parts of ferric oxide, 10 parts of hydrazine hydrate, and 28 parts of amphoteric surfactant.

[0077] The modified nanoparticle mixed liquid mainly includes modified auxiliary liquid and nanoparticles, and the mass ratio of the modified auxiliary liquid and nanoparticles is 5:1.

[0078] S1. Preparation of modified halloysite:

[0079] A. Preparation of halloysite airgel:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com