Piezoelectric fiber and preparation method thereof

A piezoelectric fiber and slurry technology, applied in the field of piezoelectric materials, can solve the problems of complicated preparation methods, difficulty in making dense and uniform diameter, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

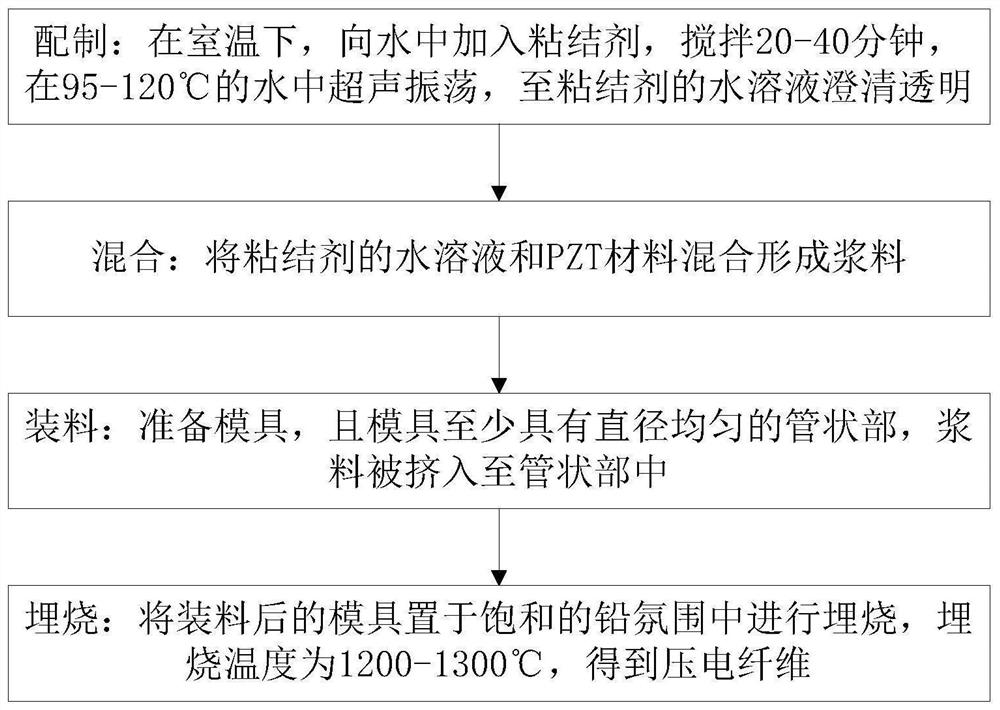

[0042] The embodiment of the present application provides a piezoelectric fiber, and the preparation method of the piezoelectric fiber includes the following steps:

[0043] Mixing: Mix the aqueous solution of the binder and the PZT material to form a slurry;

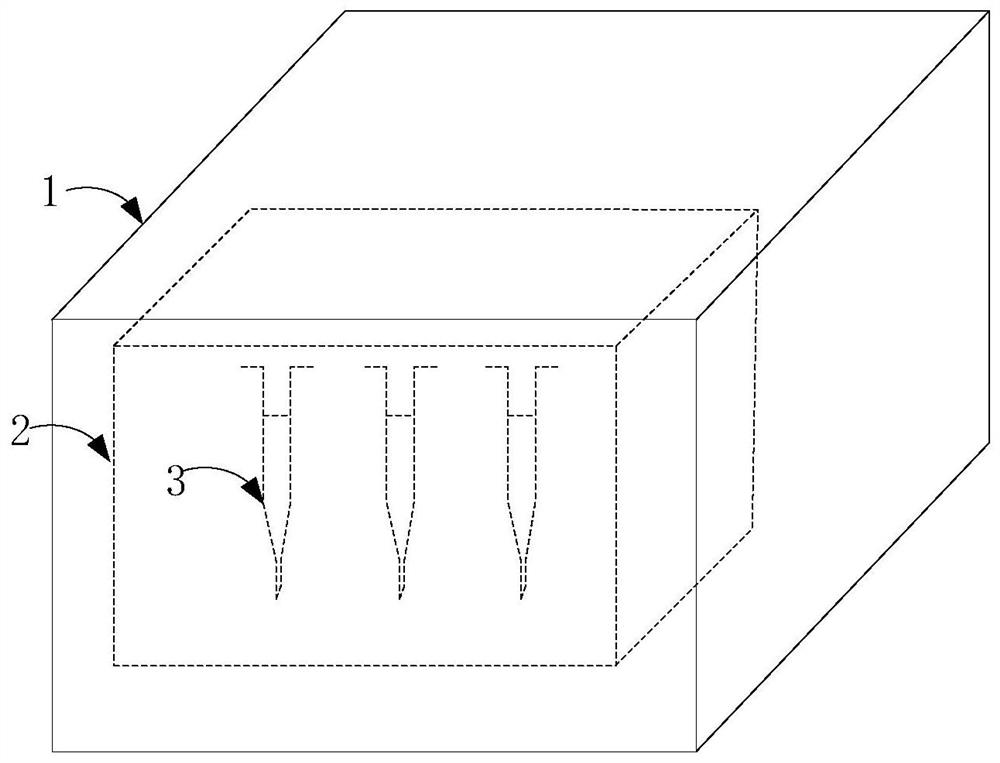

[0044] Charging: the above slurry is added into the mold, and the mold has at least a tubular part with a uniform diameter, and the above slurry is extruded into the tubular part;

[0045] Buried firing: the charged mold is placed in a saturated lead atmosphere for buried firing, and the buried firing temperature is 1200°C-1300°C to obtain piezoelectric fibers.

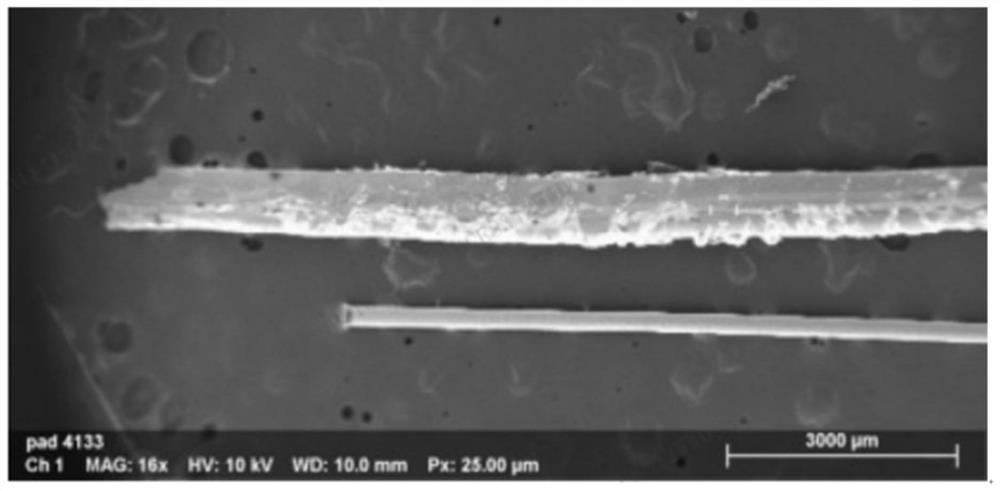

[0046] The above preparation method has the advantages of simple operation and low cost, and the piezoelectric fiber prepared by the above preparation method has the advantages of uniform diameter and high density. This can very well overcome the disadvantages of the piezoelectric fibers, such as poor compactness, when using the spinning method and other prepa...

Embodiment 1

[0082] The embodiments of the present application provide a piezoelectric fiber, such as figure 1 As shown, the preparation method of the piezoelectric fiber includes the following steps:

[0083] Preparation: at room temperature, add the binder polyvinyl alcohol to the water, stir for 30 minutes, ultrasonically oscillate in boiling water at 100 ° C until the aqueous solution of polyvinyl alcohol is clear and transparent, then cool the aqueous solution of polyvinyl alcohol to room temperature, wait for wherein, the water is deionized water, and the aqueous solution of polyvinyl alcohol is prepared according to the dosage ratio that the mass percentage of polyvinyl alcohol in the aqueous solution of polyvinyl alcohol is 5%.

[0084] Mixing: Weigh the PZT material and mix with the above-mentioned aqueous solution of polyvinyl alcohol with a prepared concentration, and use a ball mill to shake the mixed liquid for 2 hours to obtain a uniformly mixed slurry; wherein, the PZT mater...

Embodiment 2

[0090] An embodiment of the present application provides a piezoelectric fiber, and a method for preparing the piezoelectric fiber includes the following steps:

[0091] Preparation: Add binder polyvinyl alcohol to water at room temperature, stir for 20 minutes, oscillate ultrasonically in boiling water at 95°C until the aqueous solution of polyvinyl alcohol is clear and transparent, then cool the aqueous solution of polyvinyl alcohol to room temperature, wait for wherein, the water is deionized water, and the aqueous solution of polyvinyl alcohol is prepared according to the dosage ratio that the mass percentage of polyvinyl alcohol in the aqueous solution of polyvinyl alcohol is 4%.

[0092] Mixing: Weigh the PZT material and mix with the above-mentioned aqueous solution of polyvinyl alcohol with a prepared concentration, and use a ball mill to shake the mixed liquid for 4 hours to obtain a uniformly mixed slurry; wherein, the PZT material is PZT powder, PZT material The mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com