High-wear-resistance high-transparency satin glaze, preparation method and large-specification satin rock plate

A satin glaze and high wear-resistant technology, which is applied in the field of large-scale satin slabs, preparation, high wear-resistant and high-transparency satin glaze, and can solve the problem of high gloss of satin glaze, poor satin effect, and light transmission. Low rate and other problems, to achieve the effect of improving the sense of transparency, strong texture, transparency and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

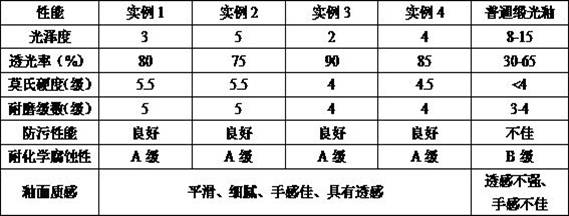

Examples

preparation example Construction

[0029] The present invention also provides a preparation method of high wear-resistant and high-transparency satin glaze, comprising the following steps:

[0030] S1, ingredients: take raw materials according to composition weight ratio;

[0031] S2. Ball milling: Put the raw materials weighed in step S1 into a ball mill, add 1-4‰ dispersant and 2-5‰ debonding agent at the same time, add water and grind for 4-6 hours to obtain glaze slurry, The fineness of the glaze slurry is 0.1-0.2% of the 10,000-hole sieve, the specific gravity of the glaze slurry is 1.85-1.90, and the flow rate of the glaze slurry is 50-70s;

[0032] S3. Sieving and removing iron: the glaze slurry prepared in step S2 is filtered through a 160-mesh double-layer sieve. After iron removal, the glaze slurry is pumped into the slurry pool to stave, and high wear-resistant and high-transparency satin glaze is obtained.

[0033] As a preferred embodiment, the dispersant is any one of sodium hydroxymethyl cellulo...

Embodiment 1

[0037] The high wear-resistant and high-transparency satin glaze of the present embodiment is composed by parts by weight: 6 parts of clay, 15 parts of high-temperature transparent frit, 10 parts of lepidolite, 4 parts of corundum powder, 5 parts of strontium carbonate, and 3 parts of barium carbonate. 5 parts of spodumene, 12 parts of dolomite, 5 parts of calcite, 5 parts of zinc oxide, 3 parts of lithium carbonate, 40 parts of potassium feldspar, and 10 parts of albite.

[0038] The preparation method of the highly wear-resistant and highly transparent satin glaze of the present embodiment is as follows:

[0039] S1, ingredients: take raw materials according to composition weight ratio;

[0040] S2. Ball milling: put the raw materials weighed in step S1 into a ball mill, add 1‰ sodium hydroxymethyl cellulose and 3‰ sodium tripolyphosphate, add water and grind for 4 hours to obtain glaze slurry, glaze The fineness of the slurry is 0.1% over 10,000-hole sieve, the specific gr...

Embodiment 2

[0044] The high wear-resistant and high-transparency satin glaze of the present embodiment has a composition by weight: 7 parts of clay, 20 parts of high-temperature transparent frit, 15 parts of lepidolite, 5 parts of corundum powder, 6 parts of strontium carbonate, and 2 parts of barium carbonate. 10 parts of spodumene, 15 parts of dolomite, 3 parts of calcite, 3 parts of zinc oxide, 5 parts of lithium carbonate, 35 parts of potassium feldspar, and 15 parts of albite.

[0045] The preparation method of the highly wear-resistant and highly transparent satin glaze of the present embodiment is as follows:

[0046] S1, ingredients: take raw materials according to composition weight ratio;

[0047] S2. Ball milling: Put the raw materials weighed in step S1 into a ball mill, add 3‰ of hydroxyethyl cellulose and 3‰ of water glass at the same time, add water and grind for 4.5 hours to obtain glaze and fine glaze slurry. The density is 0.2% of the million-hole sieve, the specific gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com