An automatic micro-tablet production equipment and its automatic processing method and application of tablets

A technology for producing equipment and tablets, which is applied in the field of automatic micro-tablet production equipment and its automatic processing of tablets, can solve the problems of broken die needles, small diameter of pressing needles, etc., and achieves the effect of improving the machine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

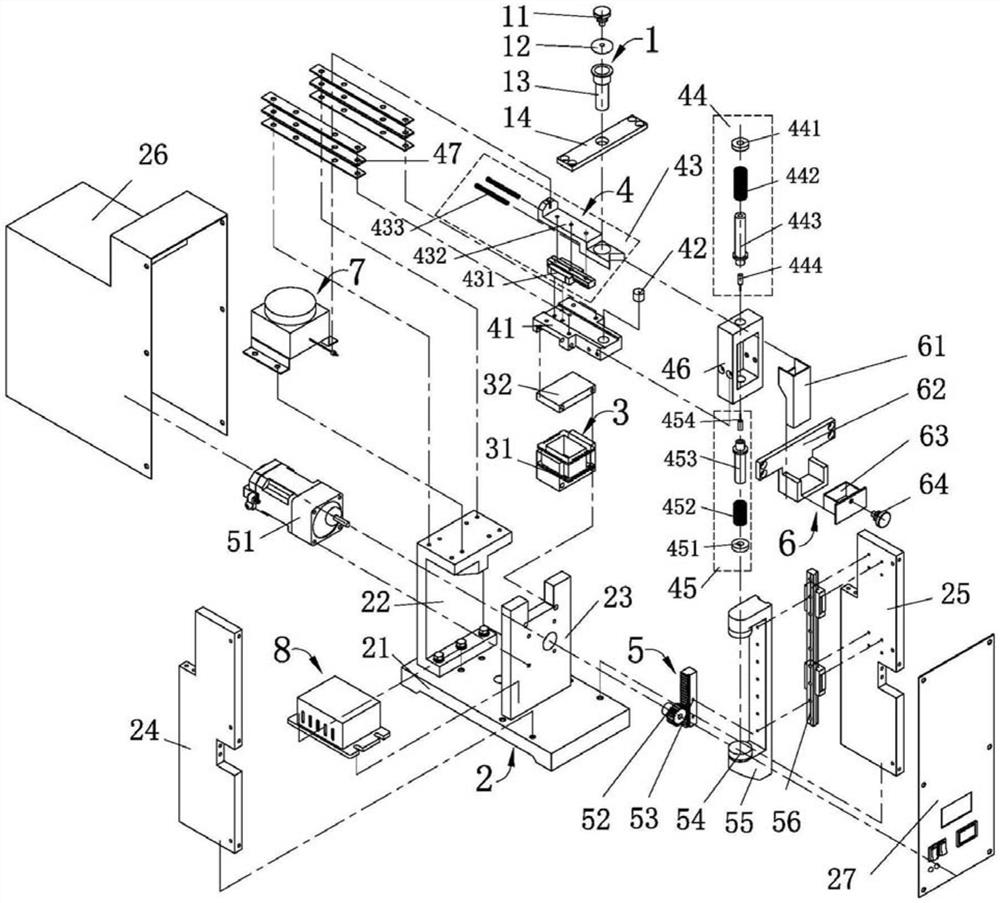

[0048] Embodiment 1 The structure of the automatic microtablet production equipment according to the present invention

[0049] The structure of the automatic mini-tablet production equipment of the present invention is as follows: figure 1 As shown, it consists of a feeding port assembly 1, a frame 2, an electromagnetic vibrator 3, a floating module 4, a pressing drive mechanism 5, a feeding port assembly 6, an electromagnetic tractor 7 and a control unit 8. Among them, the feeding port assembly 1 is composed of a handle 11, a feeding port cover 12, a feeding pipe 13, and a feeding pipe support plate 14, wherein the feeding pipe 13 is fixed on the feeding pipe supporting plate 14 by threads, and its upper end is The feeding port is isolated from the outside through the feeding port cover 12 when the powder is not added. The feeding port cover 12 normally closes the nozzle of the feeding pipe 13, and is only opened when it is necessary to add medicinal powder at the beginning...

Embodiment 2

[0064] The tablet pressing steps of the automatic mini tablet production equipment of the present invention are as follows:

[0065] 1. Turn on the switch of the automatic micro-tablet production equipment. At this time, the initial state of the system is: the electromagnetic vibrator 3 is energized to generate suction, so that the floating module 4 is sucked and fixed on the bracket; 432 is pulled back to the bottom of the feeding port assembly 1, that is, the powder adding position; the two pressing blocks 54 on the pressing connecting rod 55 are in an empty state in the middle, and are separated from the upper needle assembly 44 and the lower needle assembly 45.

[0066] Open the feeding port cover 12, add an appropriate amount of medicinal powder into the feeding funnel 432, and close the feeding port cover 12 after adding powder.

[0067] 3. Start the automatic operation switch, and the system starts to enter the automatic pressing process.

[0068] 4. The electromagneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com