A dual-beam slm forming method and system that takes into account forming efficiency and forming quality

A forming quality, double-beam technology, applied in the direction of improving process efficiency, improving energy efficiency, additive processing, etc., can solve the problems of difficult control of metallurgical defects of parts, low forming efficiency, easy deformation and cracking of parts, etc., to reduce residual stress , improve forming efficiency and prevent deformation and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

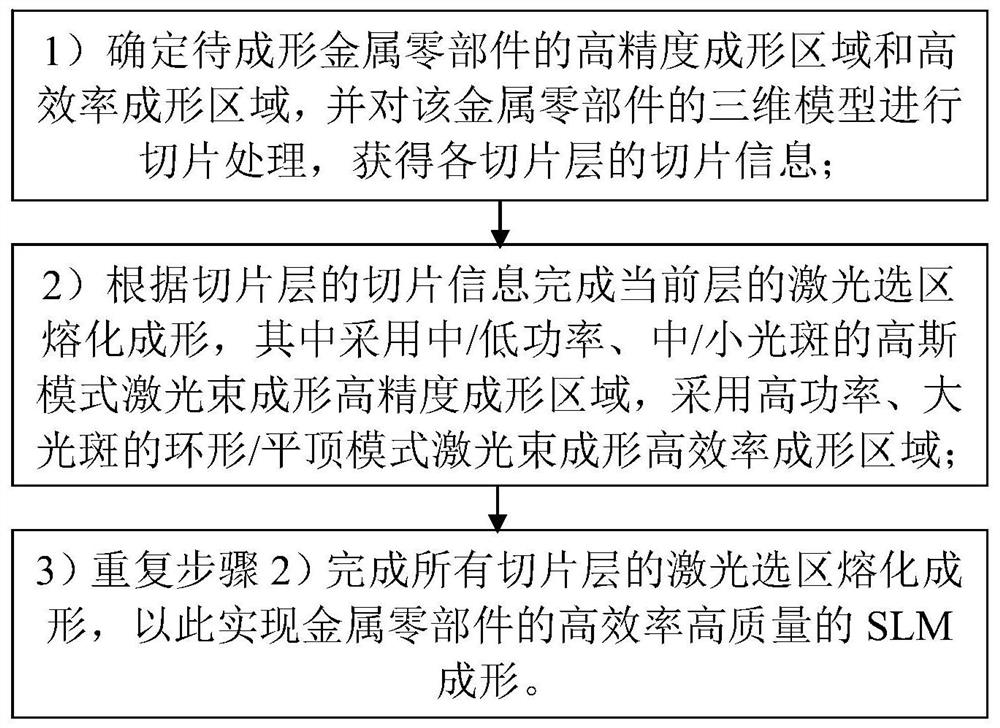

[0051] The present embodiment takes the processing of the TC4 titanium alloy pre-swirl nozzle as an example to illustrate the forming method of the present invention, and the specific steps are:

[0052] (1) Divide the digital model of the pre-swirl nozzle into a high-precision forming area and a high-efficiency forming area, and slice the digital model to obtain S-layer slice layer information (S≥2); wherein, the high-precision forming area is the nozzle , this area requires high precision, and it is difficult to carry out subsequent machining; the remaining areas can be formed by high-power laser beams, and the accuracy requirements are low, allowing subsequent machining, so it is set as a high-efficiency forming area;

[0053] (2) Apply laser selective melting to the metal powder bed according to the slice information of the first layer:

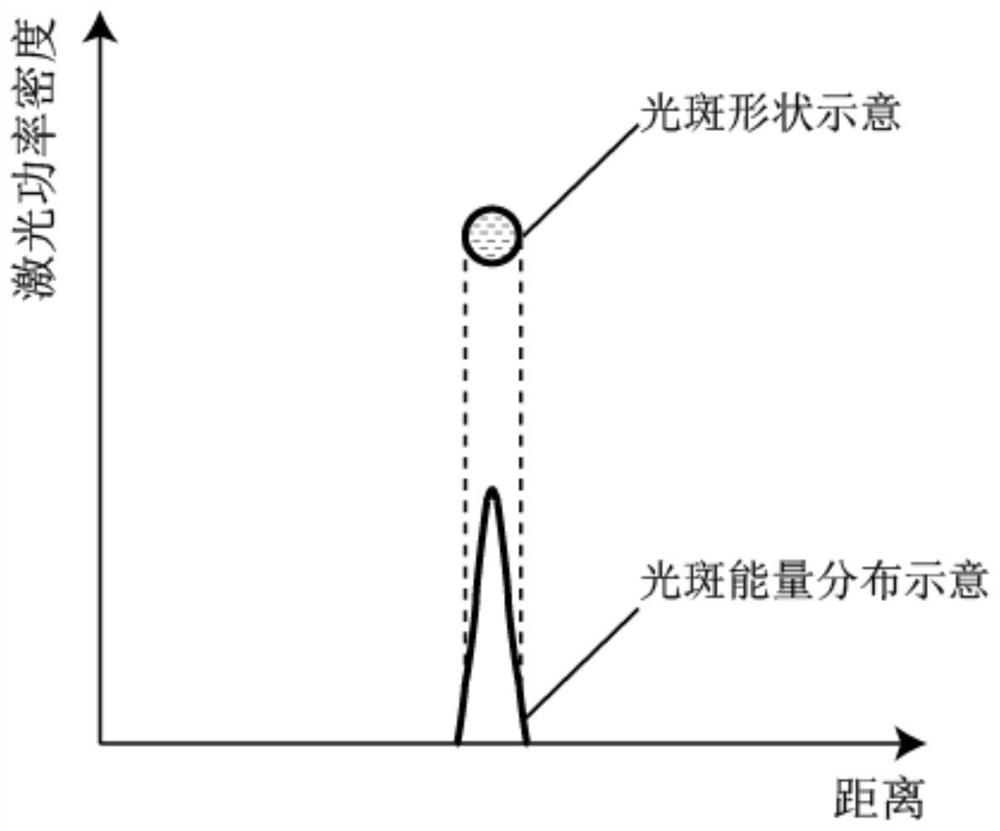

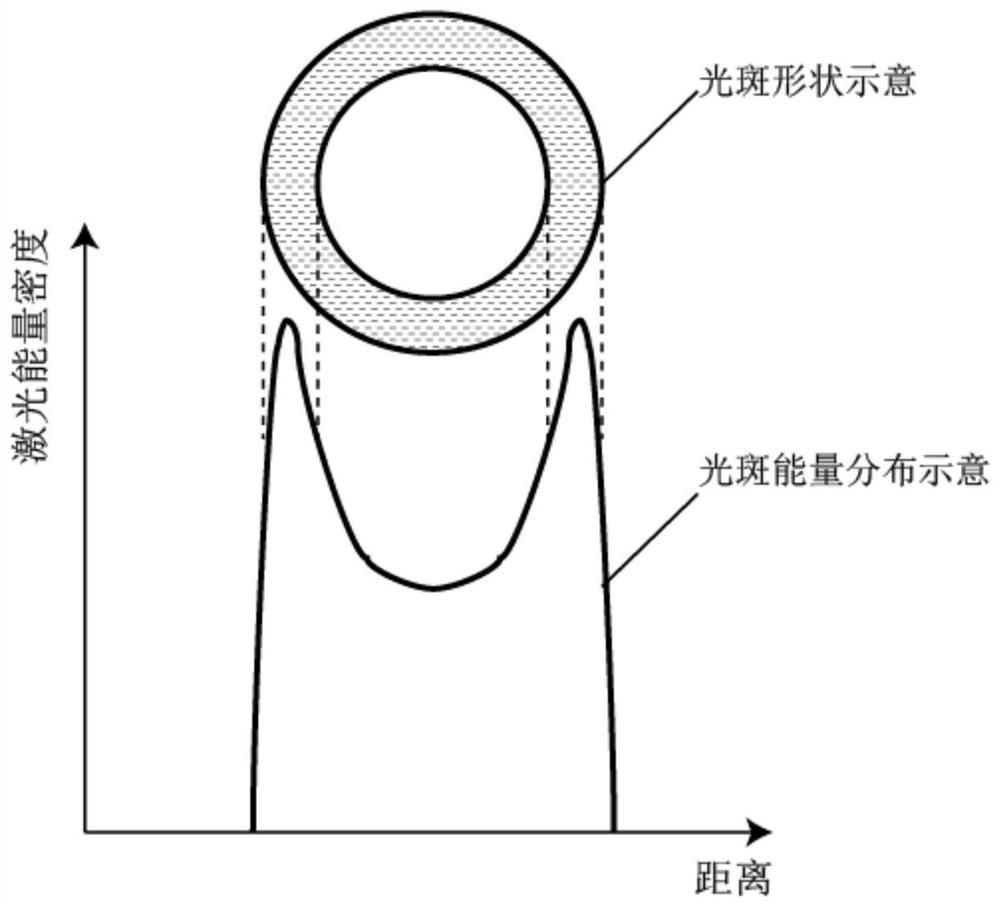

[0054] If the slice layer contains only high-precision forming areas, use figure 2 Shown is a low-power, small-spot laser beam shaping...

Embodiment 2

[0059] This embodiment takes the processing of the AlSi10Mg aluminum alloy curved surface liquid-cooled cold plate as an example to illustrate the forming method of the present invention, and the specific steps are:

[0060] (1) Divide the digital model of the liquid-cooled cold plate into a high-precision forming area and a high-efficiency forming area, and slice the digital model to obtain S-layer slice layer information (S≥2), where the high-precision forming area is The antenna pre-installation surface of the cold plate has high dimensional accuracy requirements and is difficult to carry out subsequent machining; the remaining areas can be formed by high-power laser beams, and the accuracy requirements are low, allowing subsequent machining, so it is set as a high-efficiency forming area;

[0061] (2) Apply laser selective melting to the metal powder bed according to the slice information of the first layer:

[0062] If the slice layer contains only high-precision forming ...

Embodiment 3

[0067] In this embodiment, the processing of the GH4169 nickel-based superalloy aero-engine cabin section is taken as an example to illustrate the forming method of the present invention, and the specific steps are as follows:

[0068] (1) Divide the digital model of the engine cabin into a high-precision forming area and a high-efficiency forming area, and slice the digital model to obtain S slice layer information (S≥2), where the high-precision forming area is the cabin The epitaxial cooling pipeline of this section has a complex structure and is difficult to be formed by high-power lasers, and the rest of the area is a high-efficiency forming area;

[0069] (2) Apply laser selective melting to the metal powder bed according to the slice information of the first layer:

[0070] Use 1 beam if the slice layer contains only the high-precision forming area figure 2The energy distribution shown is a Gaussian mode of medium power, medium spot laser beam shaping, where the laser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com