Difficult-to-foam sealant and preparation method thereof

A kind of beautifying agent and difficult technology, applied in the field of beautifying agent, it can solve the problems of low shrinkage rate, poor flexibility, corrosion of beautifying agent, etc., and achieve the effect of improving permeability and density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

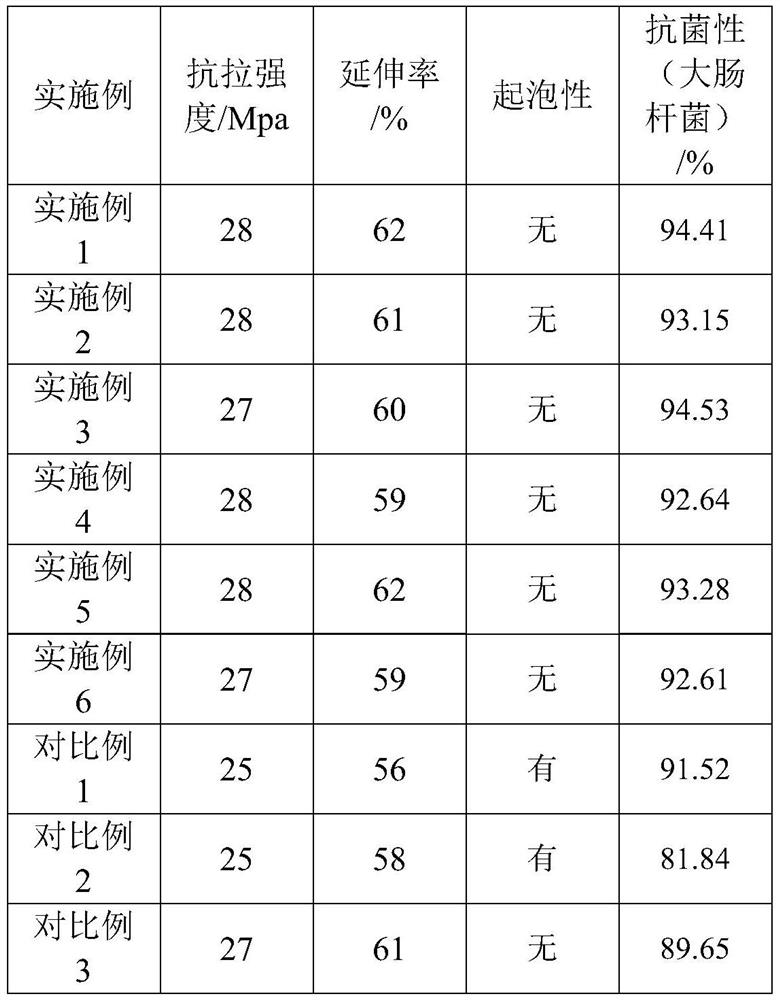

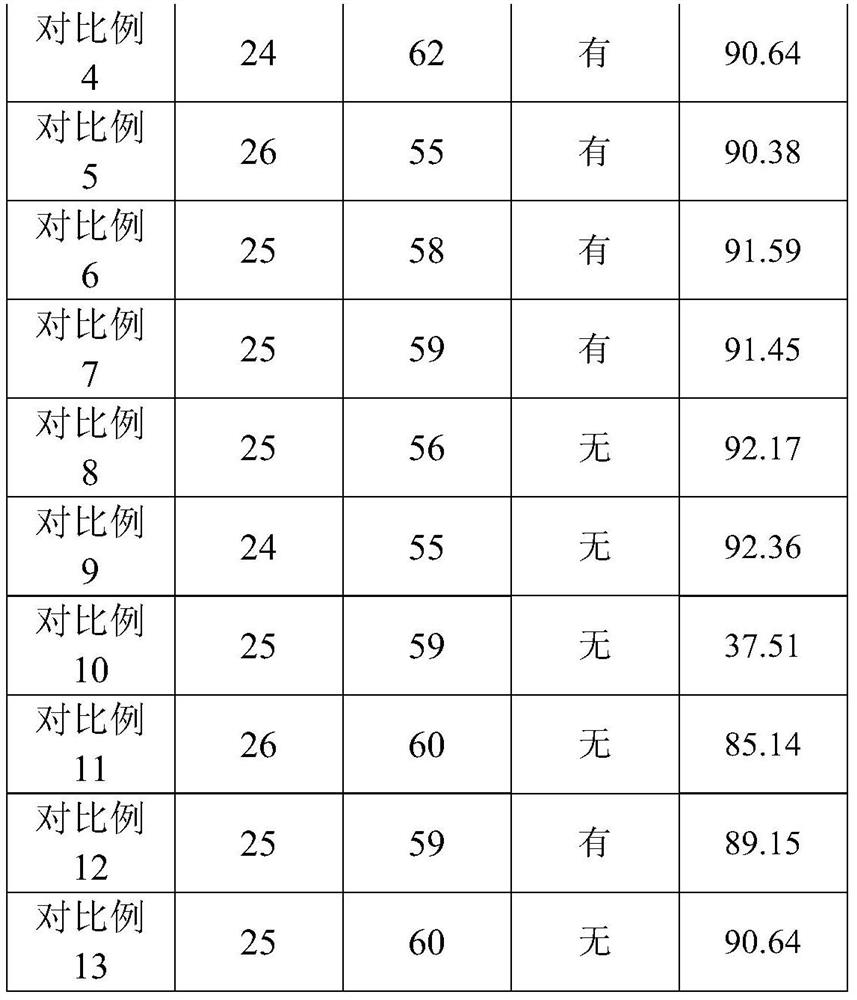

Examples

preparation example Construction

[0027] The preparation method of aliphatic isocyanate prepolymer is as follows:

[0028] Add 2-3 parts of isocyanate monomer and 1-2 parts of polycaprolactone diol to the reactor in order by weight, control the temperature of the reactor at 60-70°C, and measure the NCO value after 3 hours of reaction; when NCO When the value reaches 30%, stop the reaction and discharge the material to obtain an aliphatic isocyanate prepolymer, which can make the prepared beautifying agent solidify without NCO residue, and avoid the reaction of NCO and water to form CO 2 Cause bubbling, and micro-excess polyaspartic acid ester improves the stability of molecular structure due to the existence of nano-titanium dioxide, and is not easy to appear yellowing phenomenon.

[0029] The hot and humid environment is easy to breed microorganisms such as fungi and bacteria, and these microorganisms will damage the structure of the beauty joint agent or cause mildew. In some preferred embodiments, nano-sil...

Embodiment 1

[0036] Embodiment 1 provides a kind of beauty joint agent that is not easy to foam, including component A and component B;

[0037] Component A includes 85 parts of polyaspartic acid ester, 2 parts of leveling agent (purchased from Yangzhou Weina New Material Co., Ltd., model SY-5088), 2 parts of defoamer (purchased from Guangzhou Duomeiduo New Material Co., Ltd., the model is BK-431), 8 parts of nano-titanium dioxide, 2 parts of 3-butyl-2-(1-ethylpentyl) oxazolidine; among them, polyaspartic acid ester The viscosity at 25°C is 800-1500mPa / s, the amine value is 200-204, purchased from Shanghai Junhe Chemical Co., Ltd., the model is JH-8142; the nano-titanium dioxide is rutile type, the average particle size is 50nm, purchased from Hefei Zhonghang Nanotechnology Development Co., Ltd., model ZH-TiO250NJ; 3-butyl-2-(1-ethylpentyl) oxazolidine was purchased from Hubei Yongkuo Technology Co., Ltd.

[0038] Component B includes 85 parts of curing agent, 2 parts of antibacterial age...

Embodiment 2

[0043] Similar to Example 1, a non-foaming beautifying agent and its preparation method are provided, but the A component includes 80 parts of polyaspartic acid ester, 1 part of leveling agent, 1 part of defoamer, 5 parts of nano-titanium dioxide, 2 parts of 3-butyl-2-(1-ethylpentyl) oxazolidine; the component B is proportioned in parts by mass, including 75 parts of curing agent, 1 part antibacterial agent, 5 parts thickener.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com