Online hydrogen supply system based on alcohol fuel reforming reaction

A technology of reforming reaction and alcohol fuel, which is applied in the field of hydrogen production, can solve the problems of only 40g/L, low technology maturity, and high energy consumption of dehydrogenation, and achieve small volume and weight of the device, wide source of raw materials, and high heat utilization rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

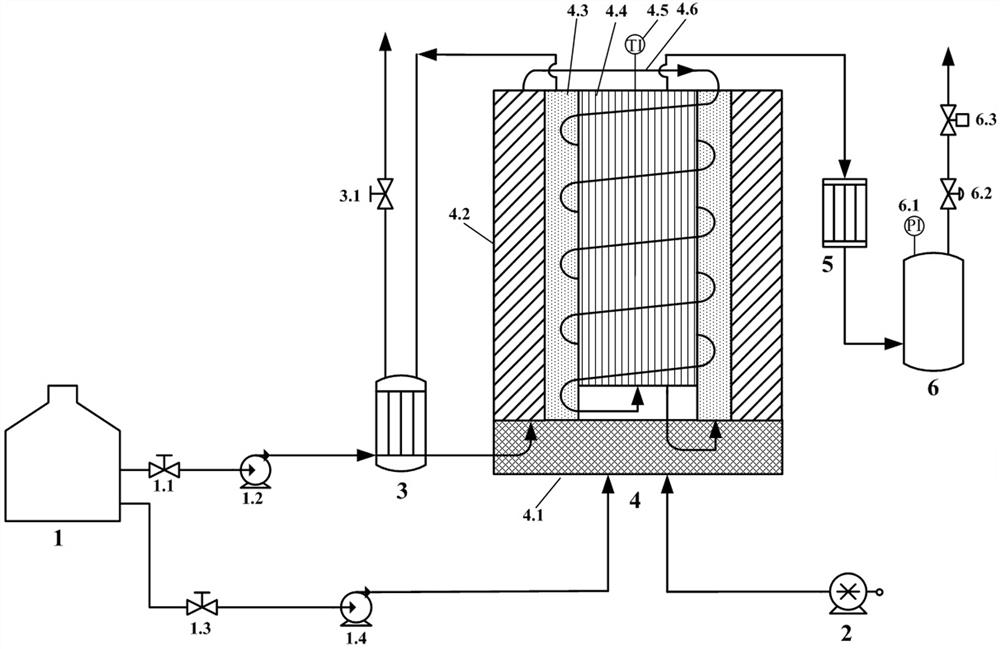

[0017] A basic example of the present invention is figure 1 As shown, an on-line hydrogen supply system based on the reforming reaction of alcohol fuels includes a raw material tank 1, a heat exchanger 3 connected to the raw material tank 1 through a raw material metering pump 1.2 and a solenoid valve 1.1, a fuel metering pump 1.4 and a The hydrogen production-purification integrated reactor 4 connected with the electromagnetic valve 1.3 and the raw material box 1, the hydrogen production-purification integrated reactor 4 is connected with the air pump 2, the cooler 5 and the hydrogen storage tank 6 connected with the cooler 5, The heat exchanger 3 is connected to the outside through the stop valve 3.1, and the hydrogen storage tank 6 is connected to the outside through the stop valve 6.2 and the back pressure valve 6.3 in turn.

[0018] The hydrogen production-purification integrated reactor 4 includes a vaporization chamber 4.1, a reforming reaction chamber 4.2, a catalytic ...

Embodiment 2

[0020] Further embodiment on the basis of Example 1: its alcohol fuel is a mixture of methanol and ethanol, the raw material stored in the raw material box is a mixture of methanol, ethanol and deionized water, and its alcohol fuel reforming reaction temperature is 450 ℃, the reaction pressure is 0.5 MPa, the alcohol water raw material stored in the raw material box 1 is used as the reaction raw material and the catalytic combustion fuel at the same time, and is transported to the hydrogen production-purification integrated reactor 4 through the raw material metering pump 1.2 and the fuel metering pump 1.4 respectively. The reforming reaction chamber 4.2 and the vaporization chamber 4.1, the vaporization chamber 4.1 of the hydrogen production-purification integrated reactor 4 are connected with the catalytic combustion chamber 4.3, and the alcohol water raw material used as catalytic combustion is simultaneously in the vaporization chamber 4.1 and the catalytic combustion chambe...

Embodiment 3

[0022] Further embodiment on the basis of embodiment 2. The difference from Example 2 is that the alcohol fuel is ethanol, the raw material stored in the raw material box is a mixture of ethanol and deionized water, the reforming reaction temperature is 550°C, the reaction pressure is 4.0MPa, and the reaction temperature of catalytic combustion is 600°C, the catalyst set in the vaporization chamber 4.1 and the catalytic combustion chamber 4.3 is Pd / Al 2 o 3 , The hydrogen purification chamber is equipped with a membrane tube type palladium alloy purification component, and the cooling method of pure hydrogen generated by the reforming reaction is water cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com