Cutting tool wear in-situ measurement device and method for manufacturing Internet of Things

A technology for manufacturing the Internet of Things and cutting tools. It is applied in the direction of manufacturing tools, measuring/indicating equipment, and metal processing machinery parts. It can solve problems such as low detection efficiency and positioning errors of disassembling and assembling cutting tools, and improve production efficiency and production quality. , Guaranteed parallelism and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

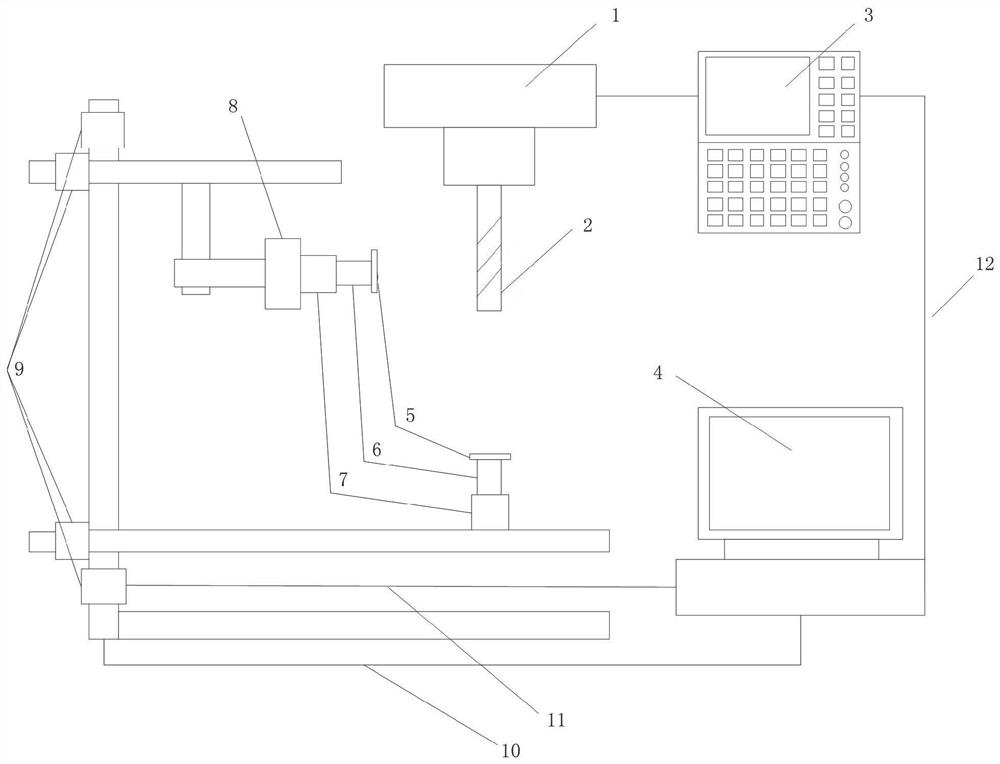

[0056] Such as figure 1 As shown, it is an embodiment of an on-site measurement device for cutting tool wear used in manufacturing the Internet of Things, which includes an industrial computer (4), which is the core processing unit of the system, and includes a camera communication module and a machine tool communication module inside , image processing and wear calculation module.

[0057] It also includes a CNC machine tool spindle (1). A tool (2) is installed on the CNC machine tool spindle (1). The tool (2) is the object to be detected in this embodiment. The tool (2) has a side edge and a bottom edge. The CNC machine tool The main shaft (1) can drive the tool (2) to rotate or to reciprocate and linearly move in the Z-axis direction.

[0058] It also includes a telecentric lens (6) and a CCD industrial camera (7), which are in two groups and are respectively facing the side edge and the bottom edge of the cutter (2), that is, between the two groups of CCD industrial camer...

Embodiment 2

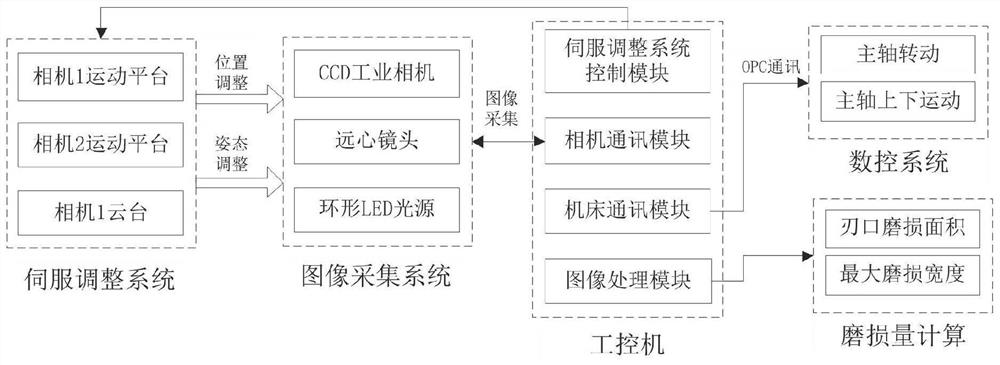

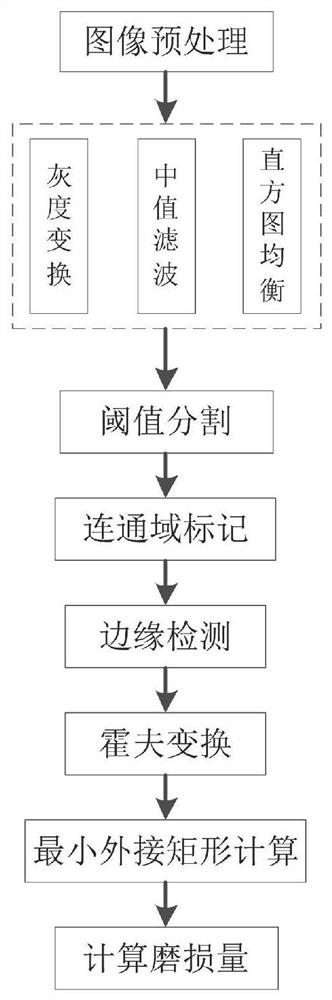

[0064] Such as figure 2 As shown, it is a flow chart of a measurement method for an in-situ measurement device for cutting tool wear used in manufacturing the Internet of Things, which mainly includes the following steps:

[0065] S1. Adjust the hardware and software configuration of the image in-position perception system; calibrate the internal and external parameters of the camera used, adjust the focal length of the lens and the intensity of the light source to ensure a clear and undistorted image. It mainly includes the following two steps:

[0066] S11. respectively calibrate the internal and external parameters of the two CCD industrial cameras (7), the focal lengths of the two telecentric lenses (6) and the intensity and direction of the two ring-shaped LED light sources (5), to ensure that a clear and distortion-free image can be obtained;

[0067] S12. Configure the shutter time and resolution of the two CCD industrial cameras (7) through the camera communication b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com