A kind of preparation method of polyamide-imide copolymerized fiber

An imide copolymer fiber and polyamide technology, applied in the field of spinning fibers, can solve the problems of insufficient ultraviolet aging resistance and mechanical properties of fibers, and process complexity, so as to achieve improved strength and ultraviolet aging resistance, and a simple process flow. High efficiency and low production environment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

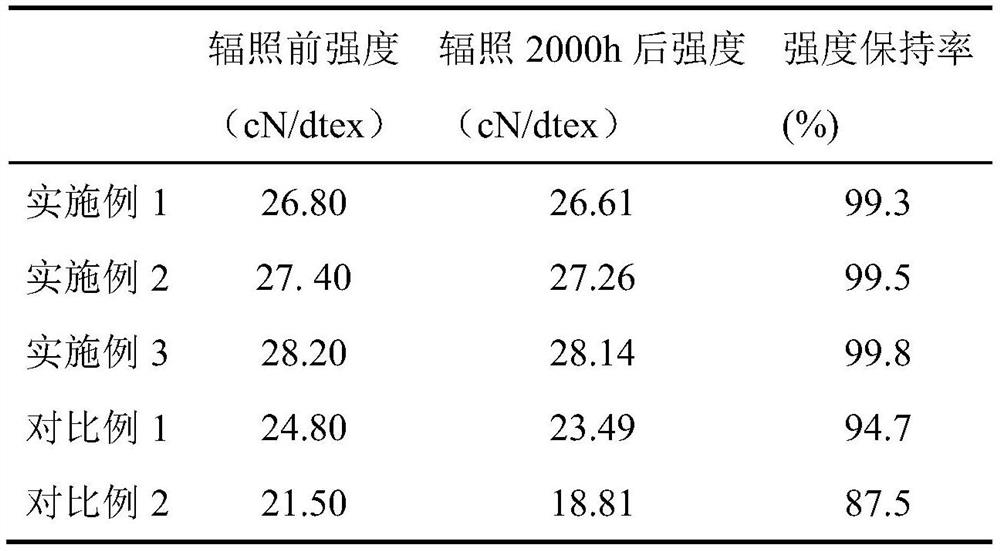

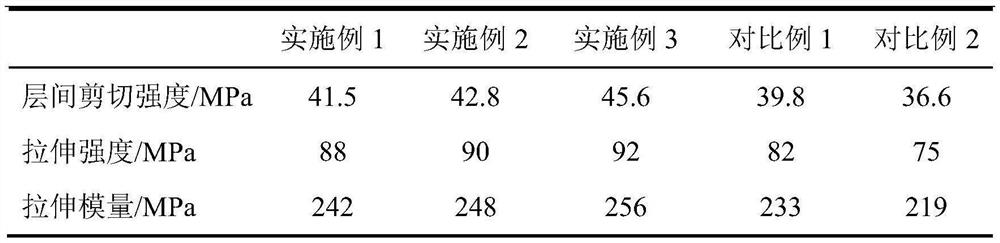

Embodiment 1

[0034] (1) Trimellitic anhydride and pyromellitic dianhydride are dissolved in N,N-dimethylacetamide at a molar ratio of 1:0.15, and under the protection of high-purity nitrogen, stirring and dissolving at -10°C to obtain a mixed solution. Keep its temperature at -10°C, control the ratio of the total molar amount of trimellitic anhydride and dianhydride monomers to the molar amount of diphenylmethane diisocyanate to be 1:1.01, and add diphenylmethane diisocyanate monomer to the mixed solution in 8 batches , the control system temperature does not exceed 20 ℃. After the feeding is completed, the temperature is raised to 85°C at 5°C / min and maintained at this temperature for 30min, and then gradually raised to 160°C at 5°C / min to obtain a copolymerized modified polyamide-imide spinning stock solution, The mass content of the stock solution is 19.2%, and the logarithmic viscosity is 2.04;

[0035] (2) After the polyamide-imide spinning stock solution obtained in the previous ste...

Embodiment 2

[0037] (1) Dissolve trimellitic anhydride and pyromellitic dianhydride in N,N-dimethylacetamide at a molar ratio of 1:0.25, and stir and dissolve at -15°C to obtain a mixed solution under the protection of high-purity nitrogen. Keeping its temperature at -15°C, the ratio of the total molar amount of trimellitic anhydride and dianhydride monomers to the molar amount of diphenylmethane diisocyanate is controlled to be 1:1.03, and the diphenylmethane diisocyanate monomer is added to the mixed solution in 8 batches , the control system temperature does not exceed 15 ℃. After the feeding is completed, the temperature is raised to 85°C at 5°C / min and kept at this temperature for 30min, and then gradually raised to 160°C at 3°C / min to obtain a copolymerized modified polyamide-imide spinning stock solution, The mass content of the stock solution is 21.4%, and the logarithmic viscosity is 2.21;

[0038] After the polyamide-imide spinning stock solution after step (1) is vacuum defoame...

Embodiment 3

[0040] (1) Dissolve trimellitic anhydride and pyromellitic dianhydride in N,N-dimethylacetamide at a molar ratio of 1:0.45, and stir and dissolve under the protection of high-purity nitrogen at -15°C to obtain a mixed solution. Keep its temperature at -15°C, the ratio of the total molar amount of trimellitic anhydride and dianhydride monomers to the molar amount of diphenylmethane diisocyanate is controlled to be 1:1.05, and the diphenylmethane diisocyanate monomer is added to the mixed solution in 8 batches , the control system temperature does not exceed 15 ℃. After the feeding is completed, the temperature is raised to 85°C at 5°C / min and maintained at this temperature for 30min, and then gradually raised to 145°C at 3°C / min to obtain a copolymerized modified polyamide-imide spinning stock solution, The mass content of the stock solution is 22.6%, and the logarithmic viscosity is 2.25;

[0041] After the polyamide-imide spinning stock solution after step (1) is vacuum defo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com