Multifunctional polyacrylate nano composite coating agent and preparation method thereof

A polyacrylate and nanocomposite technology, applied in coatings, biocide-containing paints, antifouling/underwater coatings, etc. To achieve the effect of improving hygienic properties, increasing tensile strength and elongation at break, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

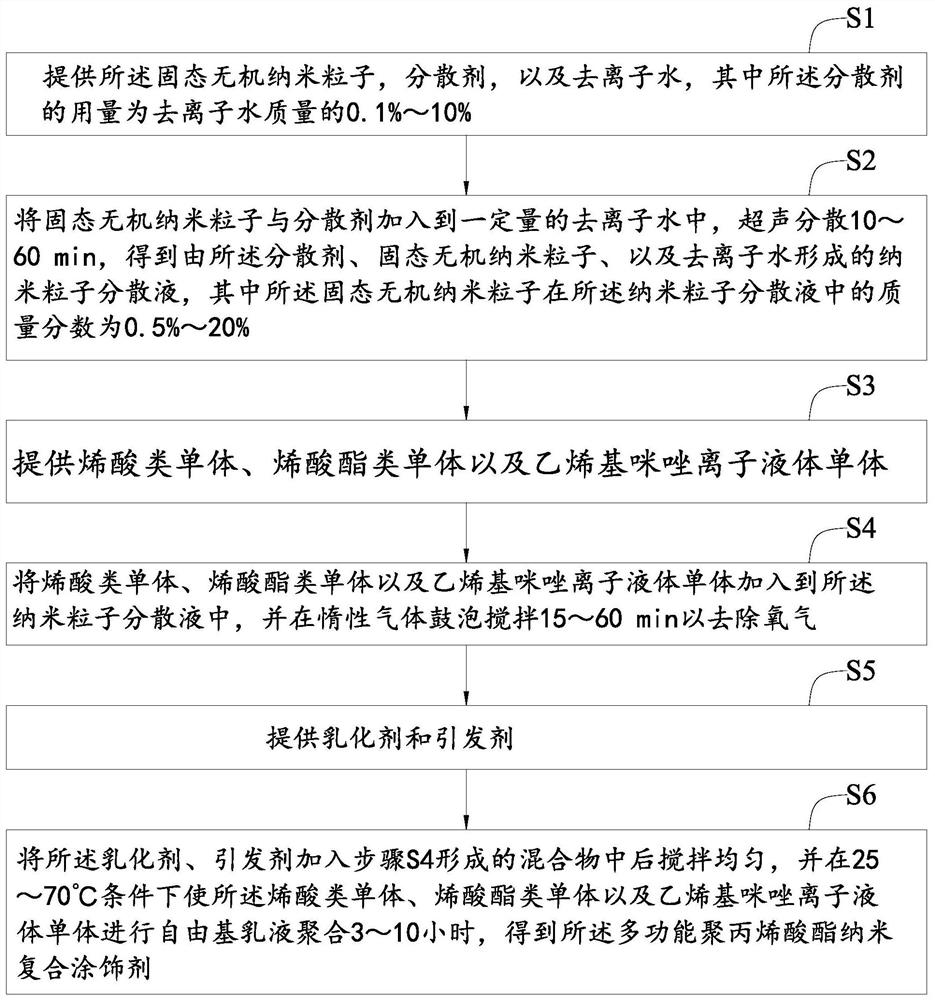

[0034] Such as figure 1 Shown, the present invention also provides a kind of preparation method of multifunctional polyacrylate nano-composite finishing agent, and it comprises the steps:

[0035] S1: providing the solid inorganic nanoparticles, a dispersant, and deionized water, wherein the amount of the dispersant is 0.1% to 10% of the mass of the deionized water;

[0036] S2: adding solid inorganic nanoparticles and a dispersant to a certain amount of deionized water, and ultrasonically dispersing for 10 to 60 minutes to obtain a nanoparticle dispersion formed by the dispersant, solid inorganic nanoparticles, and deionized water, wherein the The mass fraction of the solid inorganic nanoparticles in the nanoparticle dispersion is 0.5% to 20%;

[0037] S3: Provide enoic acid monomers, enoic acid ester monomers and vinylimidazole ionic liquid monomers;

[0038] S4: adding enoic acid monomers, enoic acid ester monomers, and vinylimidazole ionic liquid monomers into the nanopa...

Embodiment 1

[0045] Add 1.0 parts of nano-alumina with a particle size of 15nm and 0.5 parts of citric acid to 100 parts of deionized water, and ultrasonically disperse for 20 minutes at a frequency of 40kHz and a power of 350W to obtain nano-alumina with a mass fraction of 1%. Dispersions.

[0046] Get 7.2 parts of acrylic acid, 10.2 parts of methyl methacrylate, 12.8 parts of butyl acrylate and 7.3 parts of 1-vinyl-3-methylimidazole chloride and join the above-mentioned nano-alumina dispersion with a mass fraction of 1%, nitrogen Bubble and stir for 20 minutes to remove oxygen, add 1.0 part of sodium lauryl sulfate and 0.5 part of ammonium persulfate, and heat-initiate polymerization at 60°C for 4 hours to obtain a multifunctional polyacrylate nanocomposite coating agent.

Embodiment 2

[0048] Add 10 parts of nanometer zirconium hydroxide with a particle size of 30nm and 4 parts of propylene glycol methyl ether to 100 parts of deionized water, and ultrasonically disperse it for 50 minutes at a frequency of 50kHz and a power of 400W to obtain nanometer particles with a mass fraction of 5%. Zirconium hydroxide dispersion.

[0049] Get 12.9 parts of methacrylic acid, 19.2 parts of butyl acrylate, 13.1 parts of 2-methoxyethyl acrylate and 10.2 parts of 1-vinyl-3-ethylimidazole bromide and add them to the above-mentioned nano hydrogen with a mass fraction of 5%. In the zirconia dispersion liquid, helium gas was bubbled and stirred for 60 minutes to remove oxygen, 2.0 parts of sodium dodecylbenzenesulfonate and 1.0 part of potassium persulfate were added, and thermally initiated polymerization at 75°C for 3 hours to obtain multifunctional polyacrylate Nanocomposite coating agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com