Polyvinyl chloride-graphene composite material and preparation method and application thereof

A composite material, polyvinyl chloride technology, applied in the direction of electrical components, magnetic field/electric field shielding, etc., can solve the problems of poor compatibility, achieve the effects of low-cost preparation, good adsorption, and simplified process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

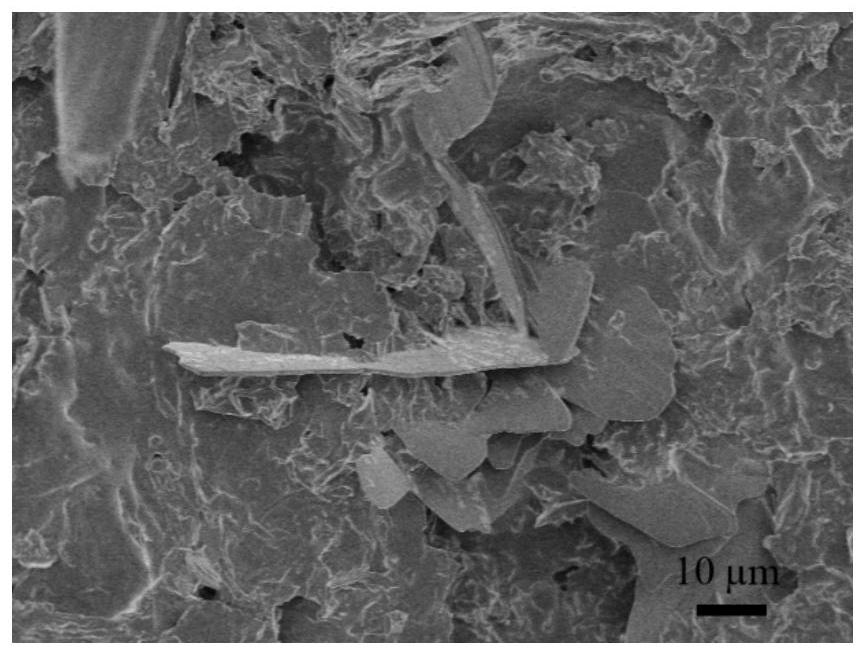

Image

Examples

preparation example Construction

[0036] A preparation method of polyvinyl chloride-graphene composite material, the steps are as follows:

[0037] (1) Preparation of phenyl-dicarboxylate-modified graphene: add graphite powder and phenyl-dicarboxylate plasticizer into a ball mill jar at a mass ratio of 1:3 to 1:5, fix it on a ball mill and Ball milling at a speed of 300-800rpm / min for 10-20 hours to obtain phenyl dicarboxylate-modified graphene;

[0038] (2) By weight, polyvinyl chloride (PVC) resin, phenyl dicarboxylate modified graphene, phenyl dicarboxylate plasticizer, heat stabilizer, lubricant, compatibilizer, processing aid Mix evenly to obtain a mixture; wherein, the weight fraction of raw materials is as follows: 100 parts of polyvinyl chloride resin, 0.5 to 5 parts of phenylenedicarboxylate modified graphene, 20 to 40 parts of phenylenedicarboxylic acid ester plasticizer, heat 1 to 5 parts of stabilizer, 0.5 to 3 parts of lubricant, 1 to 5 parts of compatibilizer, and 0.5 to 3 parts of processing ai...

Embodiment 1

[0048] (1) Graphite powder and dioctyl phthalate (DOP) are packed in a ball mill jar at a mass ratio of 1:3, fixed in a ball mill and ball milled at a speed of 800rpm for 20h to obtain DOP-modified graphene.

[0049] (2) By weight, 100 parts of PVC resin, 1 part of DOP modified graphene, 30 parts of DOP, 2 parts of composite lead salt stabilizer, 0.6 part of paraffin, 2 parts of chlorinated vinyl chloride, methyl methacrylate (MMA 3 parts of ) / acrylate copolymer was added to the torque rheometer, and kneading process was carried out at 165°C and 80 rpm for 5 minutes, so that the powder was melted into a uniform block solid, which was the masterbatch.

[0050] (3) Plasticize the masterbatch on a double-roll mill (the temperature of the front and rear rolls is set to 170°C and 172°C, respectively) for 20 minutes, then heat press it on a flat vulcanizer at 180°C and a pressure of 15MPa for 15 minutes, and then cool it off. The polyvinyl chloride-graphene composite material was ob...

Embodiment 2

[0052] (1) Graphite powder and dioctyl phthalate (DOP) are packed in a ball mill jar at a mass ratio of 1:4, fixed in a ball mill and milled at a speed of 600 rpm for 15 hours to obtain DOP-modified graphene.

[0053] (2) By weight, 100 parts of PVC resin, 2 parts of DOP modified graphene, 30 parts of DOP, 2 parts of composite lead salt stabilizer, 0.6 part of paraffin, 2 parts of chlorinated vinyl chloride, methyl methacrylate (MMA 3 parts of ) / acrylate copolymer was added to the torque rheometer, and kneading process was carried out at 165°C and 80 rpm for 5 minutes, so that the powder was melted into a uniform block solid, which was the masterbatch.

[0054] (3) Plasticize the masterbatch on a double-roll mill (the temperature of the front and rear rolls is set to 170°C and 172°C, respectively) for 20 minutes, then heat press it on a flat vulcanizer at 180°C and a pressure of 15MPa for 15 minutes, and then cool it off. The polyvinyl chloride-graphene composite material was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com