Preparation method and application of boron oxide quantum dots

A technology of quantum dots and boron oxide, which is applied in the field of quantum dot preparation, can solve the problems of target material microscopic shape limitation, waste materials, etc., and achieve the effect of broad commercial application prospects, environmental friendliness, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

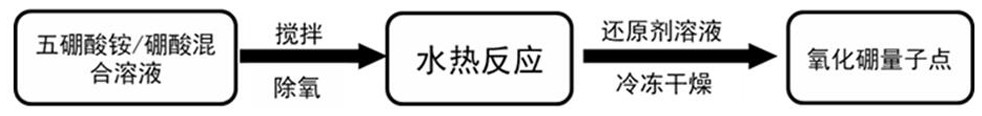

Method used

Image

Examples

Embodiment 1

[0029] (1) Disperse 1.6g of ammonium pentaborate and 1.6g of boric acid in 20mL of deionized water and stir evenly, then fill in an inert gas to remove oxygen to obtain a mixed solution of ammonium pentaborate / boric acid, and the stirring time is 1.0h, deoxygenation The time is 0.5h;

[0030] (2) Further hydrothermal reaction to obtain the initial product solution, the set temperature is 180°C, and the holding time is 12h;

[0031] Then add 0.5mL sodium borohydride solution, stir for 1h, then centrifuge at 3500rpm for 15min to obtain boron oxide quantum dot solution;

[0032] (3) The boron oxide quantum dot solution was frozen in a refrigerator, and then dried in a freeze dryer at a drying temperature of -45°C for 24 hours to obtain boron oxide quantum dot powder.

[0033] process such as figure 1 shown.

Embodiment 2

[0035] (1) Disperse 1.6g of ammonium pentaborate and 1.6g of boric acid in 20mL of deionized water and stir evenly, then fill in an inert gas to remove oxygen to obtain a mixed solution of ammonium pentaborate / boric acid, and the stirring time is 1.0h, deoxygenation The time is 1h;

[0036] (2) Further hydrothermal reaction to obtain the initial product solution, set the temperature at 200°C, and hold for 16 hours; then add 0.5mL hydrazine hydrate solution, stir for 1 hour, and then centrifuge at 3500rpm for 15 minutes to obtain the boron oxide quantum dot solution;

[0037] (3) The boron oxide quantum dot solution was frozen in a refrigerator, and then dried in a freeze dryer at a drying temperature of -45°C for 24 hours to obtain boron oxide quantum dot powder.

Embodiment 3

[0039] (1) Disperse 1.6g of ammonium pentaborate and 1.6g of boric acid in 20mL of deionized water and stir evenly, then fill in an inert gas to remove oxygen to obtain a mixed solution of ammonium pentaborate / boric acid, and the stirring time is 1.0h, deoxygenation The time is 0.5h;

[0040] (2) Further hydrothermal reaction to obtain the initial product solution, the set temperature is 180°C, and the holding time is 12h;

[0041] Then add 0.5mL hydrazine hydrate and 0.5mL sodium borohydride mixed solution, stir for 1h, then centrifuge at 3500rpm for 15min to obtain boron oxide quantum dot solution;

[0042] (3) The boron oxide quantum dot solution was frozen in a refrigerator, and then dried in a freeze dryer at a drying temperature of -45°C for 24 hours to obtain boron oxide quantum dot powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com