Composition, coating, Q690 coating-free bridge steel welding rod and preparation method thereof

A technology of composition and bridge steel, applied in the field of materials, can solve the problems of not meeting the welding strength requirements of Q690 paint-free bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

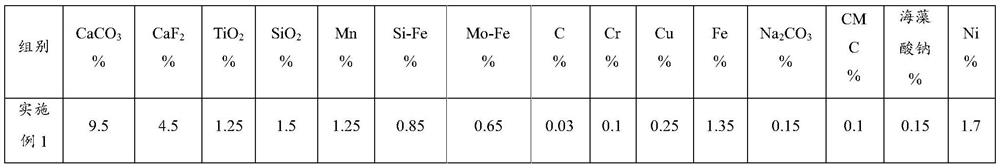

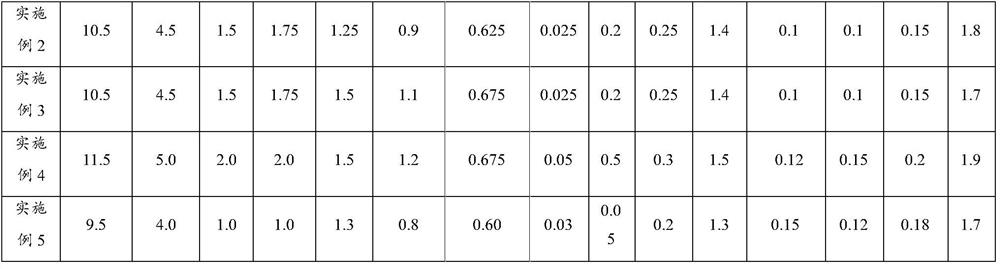

Examples

preparation example Construction

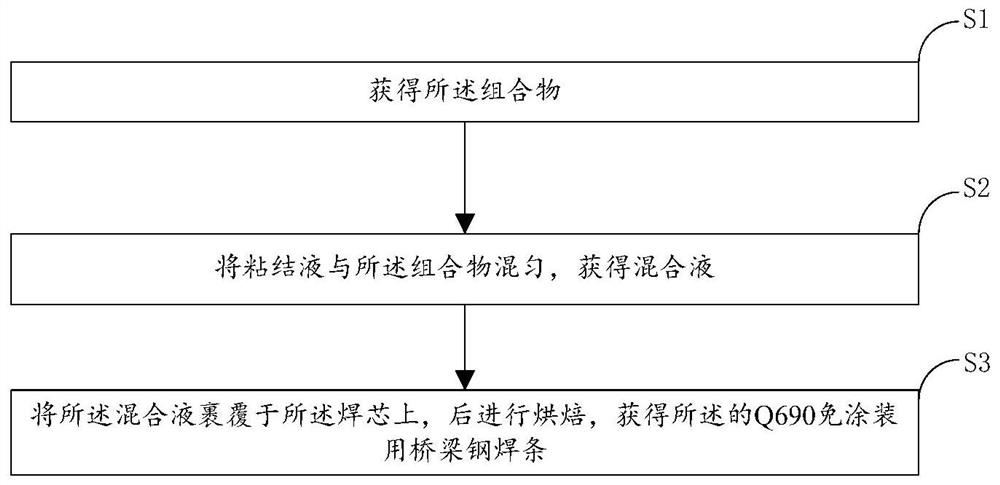

[0051] According to another typical embodiment of the present invention, a kind of preparation method of said Q690 bridge steel welding rod for exempting from painting is provided, such as figure 1 As shown, the method includes:

[0052] S1, obtaining the composition;

[0053] S2, mixing the adhesive liquid with the composition to obtain a mixed liquid;

[0054] S3. Coating the mixed solution on the welding core and then baking to obtain the Q690 coating-free bridge steel welding rod.

[0055] In this embodiment,

[0056] In the step S2, the mass ratio of the composition to the binding liquid is 100:20-24; if the ratio is too low, the wet powder is dry, the eccentricity of the production process is not easy to control, the coating is tight, and the alloy The elements will increase; if it is too high, the wet powder is too wet, and the production pressure is not enough, resulting in a low survival rate of the finished product.

[0057] The bonding liquid is water glass.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com