Hammer pounding and peeling device for wheat flour production

A technology of wheat flour and push plate, which is applied in application, grain pod removal, grain germ removal, etc. It can solve the problems of low efficiency and increase the workload of staff, and achieve the effects of high flexibility, easy maintenance, and simple and reasonable device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

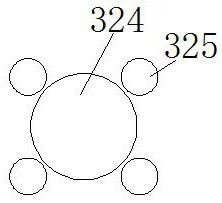

[0029] Such as Figure 1-4 As shown in , a hammering and peeling device for wheat flour production includes a hammering platform 1, and the front and rear sides of the hammering platform 1 are provided with limiting partitions 11 perpendicular to the hammering platform 1, and the limiting The middle position of dividing plate 11 is respectively provided with the longitudinal push plate 13 that can move back and forth, and described longitudinal push plate 13 is driven by longitudinal cylinder 14, and longitudinal cylinder 14 is fixedly connected with longitudinal push plate 13 by longitudinal connecting rod 141; A left push plate 42 is provided between the left side and the spacer partition 11, and the left push plate 42 is driven by the left cylinder 4, and the left cylinder 4 is fixedly connected with the left push plate 42 by the left connecting rod 41; The right push plate 52 is arranged between the right side and the limit partition plate 11, and the right push plate 52 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com