Closed annular metal part cutting, bending, forming and discharging device and working method

A metal parts, bending and forming technology, applied in the direction of wire processing, wire manufacturing rings, and other household appliances, etc., can solve the problems of low part qualification rate, long manufacturing time, low production efficiency, etc., and achieve high production efficiency and manufacturing debugging. Convenience, simple and reasonable device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

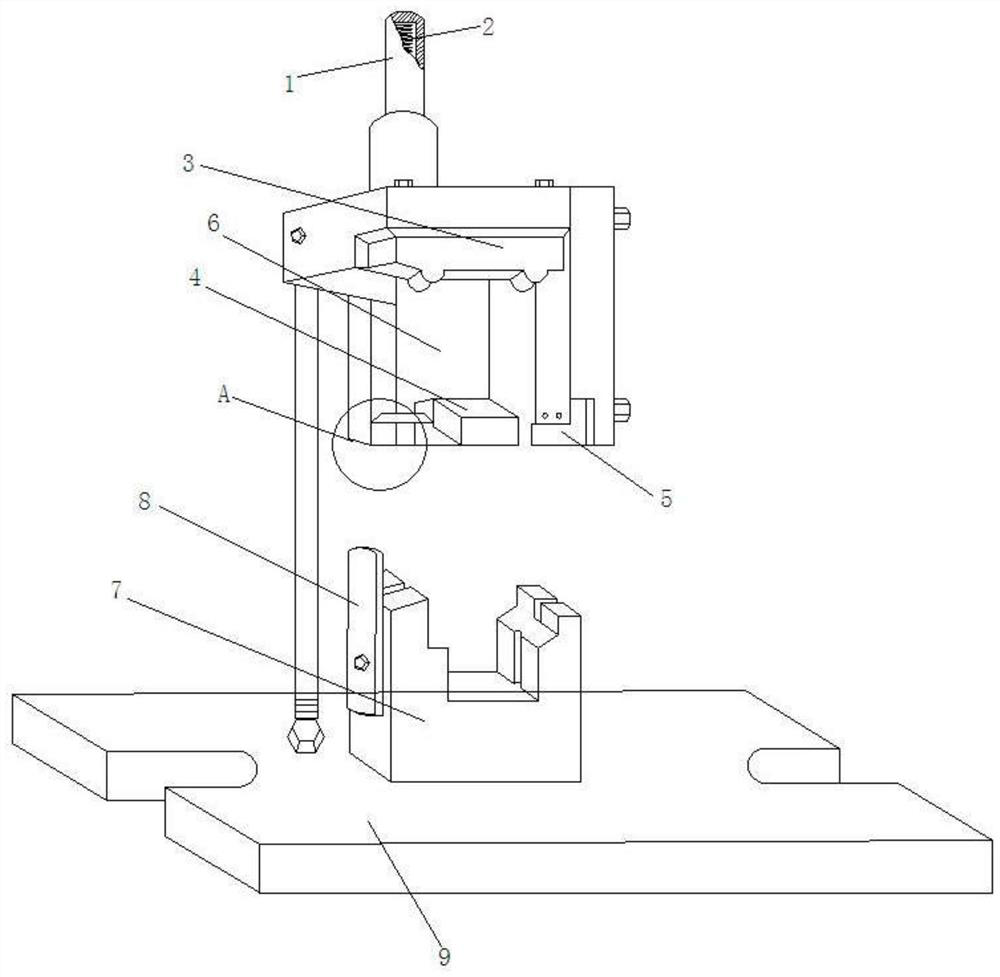

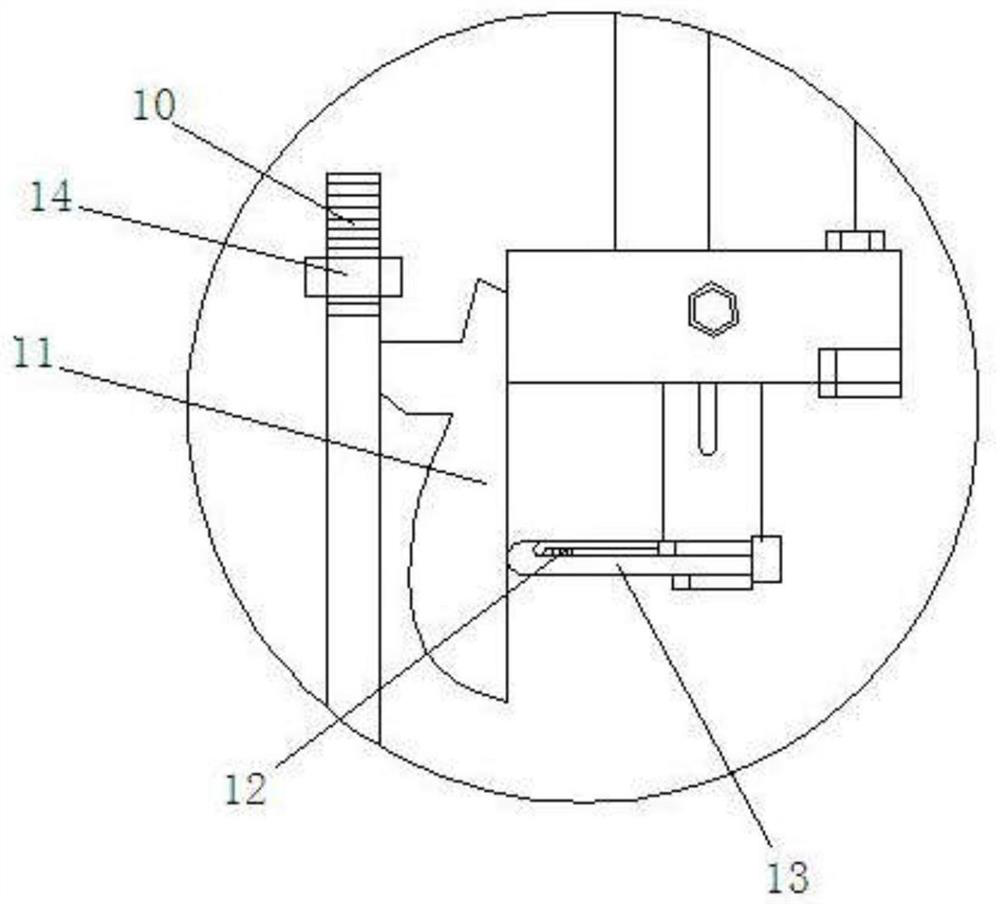

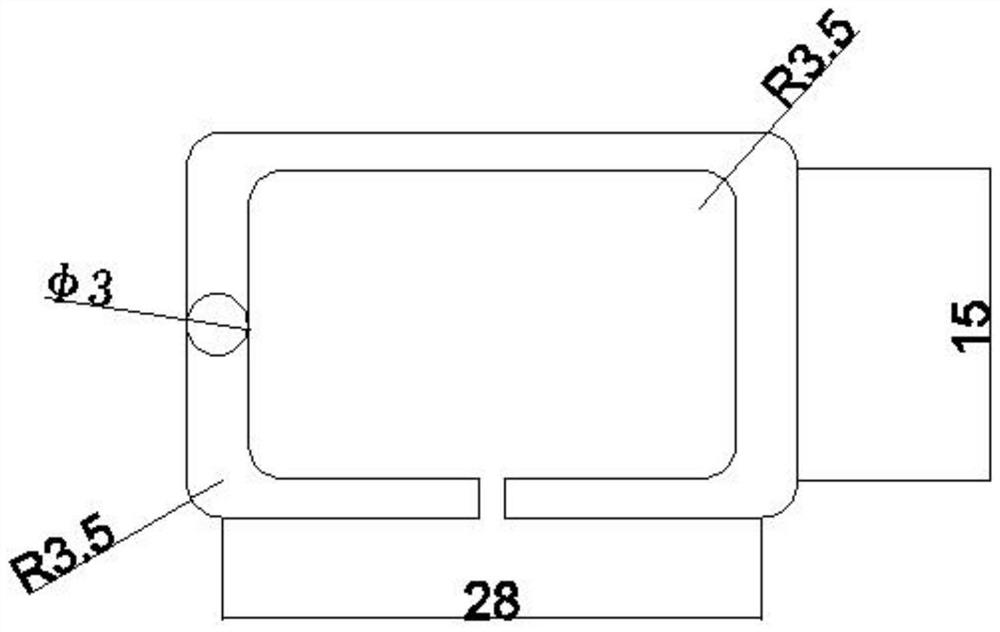

[0016] Such as Figure 1-4 As shown, the invention discloses a cutting and bending forming unloading device for a closed ring metal part, which includes three parts: an upper die part, a lower die part and a discharge part.

[0017] The upper mold part is made up of die handle 1, spring 2, binder plate 3, punch 4, cutter 5 and upper template 6; spring 2 is installed in the described die handle 1, and described punch 4 Installed on the upper template 6, the punch 4 is integrated with the upper template 6, the upper template 6 is connected with the handle 1, and the punch 4, the upper template 6 and the handle 1 are two-stage Sliding fit; a binder plate 3 and a cutter 5 are also installed on the upper template 6, the binder plate 3 is positioned above the punch 4, and the cutter 5 is positioned on the right side of the punch 4.

[0018] Described lower mold part is made up of die 7, adjustment baffle plate 8 and base 9; Described die 7 is installed on the base 9, and described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com