Non-contact glass temperature measuring system and method based on laser interference

A glass temperature, non-contact technology, applied in the field of physical industrial technology research, can solve problems such as temperature measurement range limitation and measurement accuracy impact, and achieve the effects of convenient operation, low cost, and simple and reasonable device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

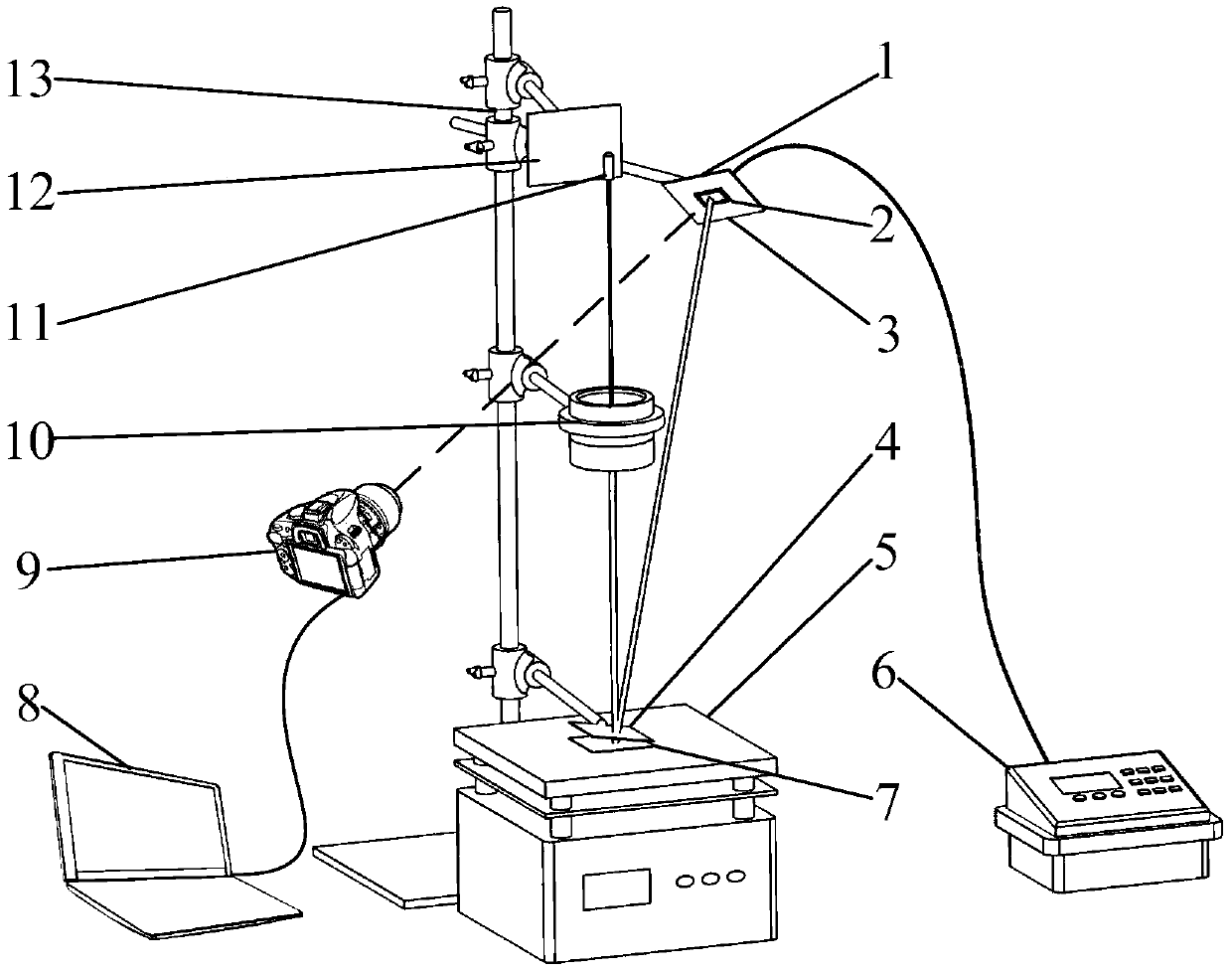

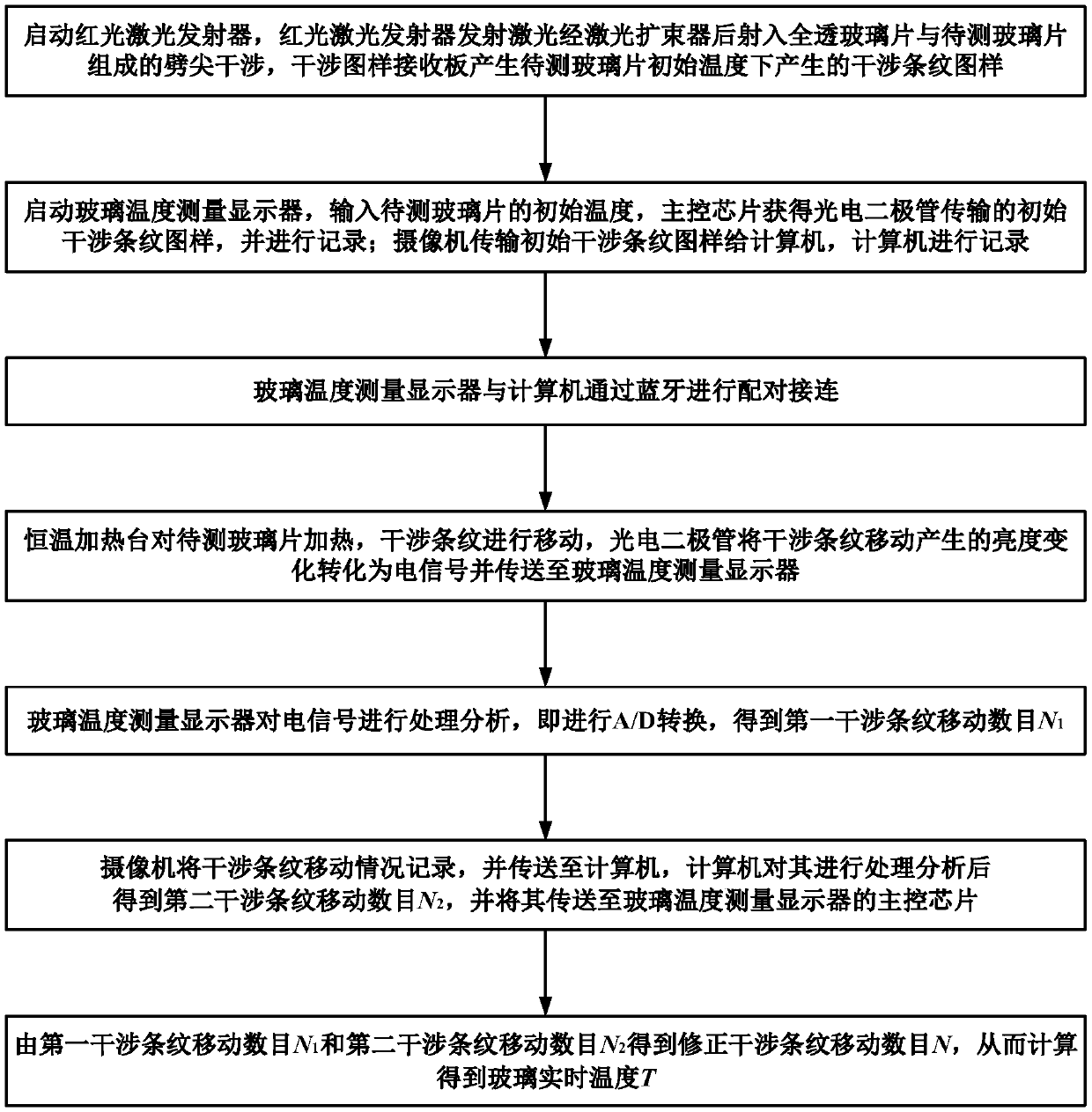

[0042] A non-contact glass temperature measurement system based on laser interferometry, such as figure 1 As shown, it includes a transmitting module 12, a laser beam expander 10, a fully transparent glass sheet 4, a constant temperature heating table 5, a receiving module 3, a glass temperature measurement display 6, a camera 9, a computer 10, and a support frame 13;

[0043] The transmitting module 12, the laser beam expander 10, and the fully transparent glass sheet 4 are all on the support frame, and are vertically discharged from top to bottom; the constant temperature heating table 5 is directly below the transparent glass sheet 4; the receiving module 3 Located obliquely above the fully transparent glass sheet 4; the receiving module 3 is connected to the glass temperature measurement display 6; the camera 9 is connected to the computer 10;

[0044] The emitting module 12 includes a red laser emitter 11; the red laser emitter 11 is a 5V copper semiconductor laser tube f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com