Normal-pressure tool-changing and pressure-detecting mounting bracket for shield tunneling machine

A technology for installing brackets and shield machines, which is applied in the direction of machine/bracket, supporting machine, mechanical equipment, etc., which can solve the problems of inconvenient manual installation and operation, large volume, etc., to prevent overturning, and the device structure is simple and reasonable. , the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the objects, technical solutions, and advantages of the present invention more clearly, the technical solutions in the embodiments of the present invention will be described in contemplation in the embodiments of the present invention, and will be described, and the embodiments described in the embodiments of the present invention will be described. It is a part of the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, those of ordinary skill in the art will belong to the scope of the present invention without all other embodiments obtained without creative labor.

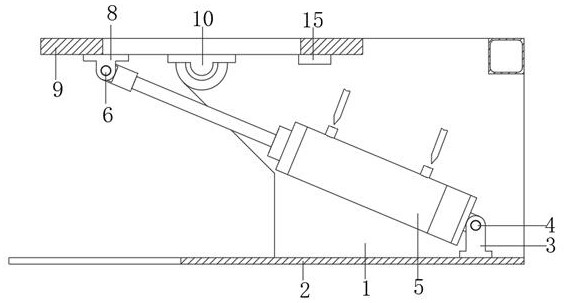

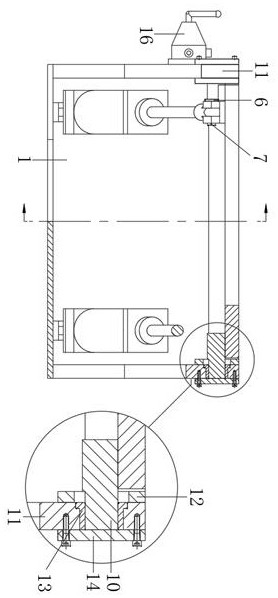

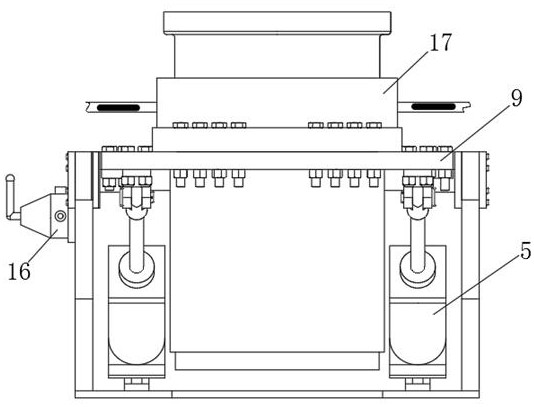

[0030] See Figure 1 ~ 8 One shield machine is used for normal pressure switching tool, including the body 1, the rear pin shaft 4, the front pin 6, and the bearing 13, the body 1 is fixedly connected to the base 2, the base 2 is symmetrical. There are two groups of bounters, the post ear 3 hinges the fixing end of the cylinder 5 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com