Al2O3/ZrN double-layer diffusion barrier layer for copper interconnection line and preparation method thereof

A technology of barrier layer and copper interconnect, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, electrical components, etc. Barrier properties, improved interfacial bonding, reduced effects of copper wiring resistance increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

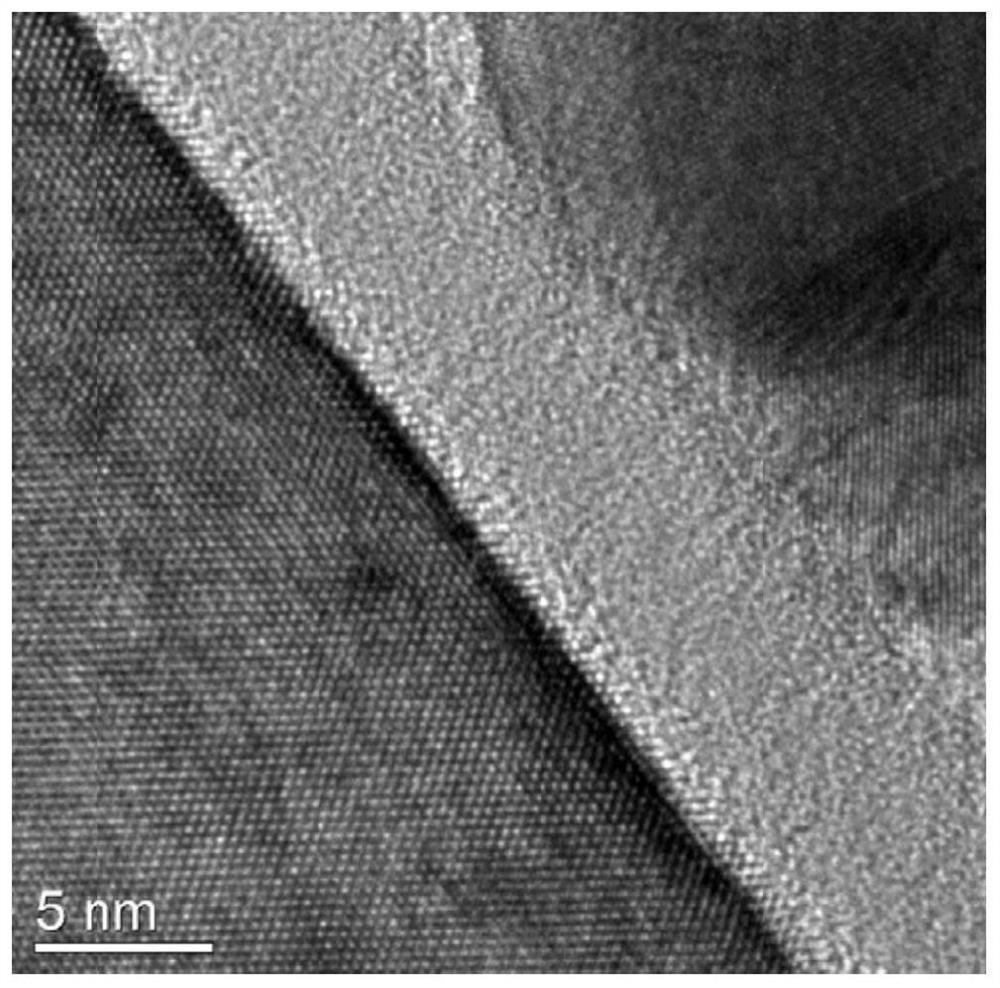

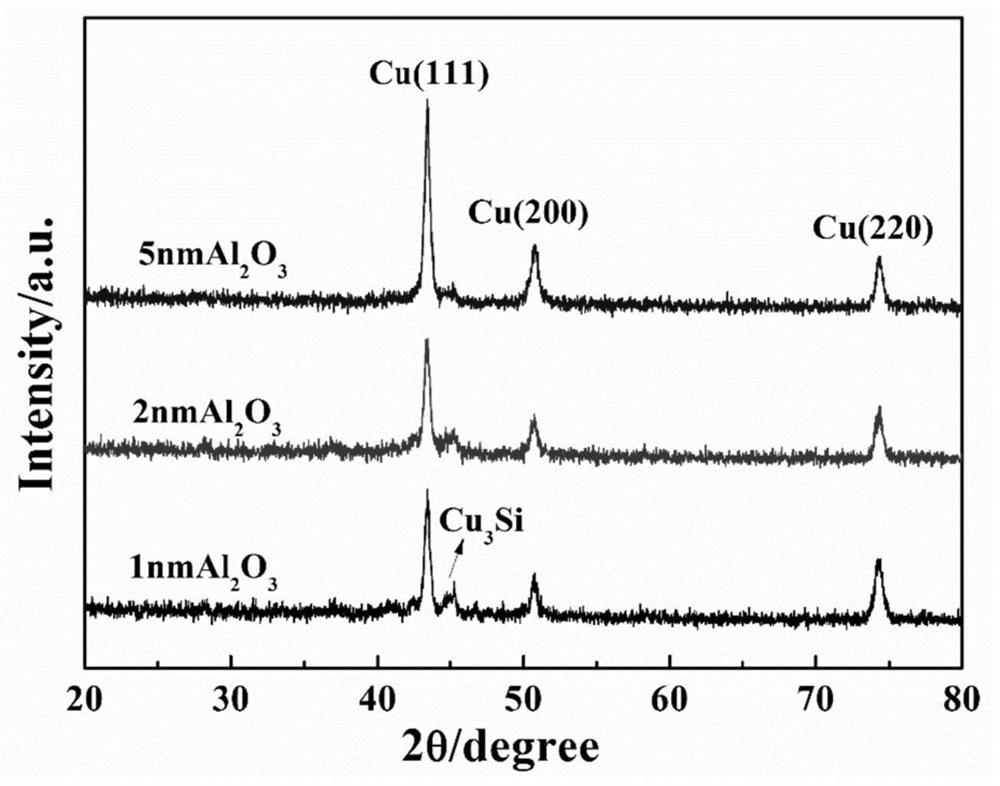

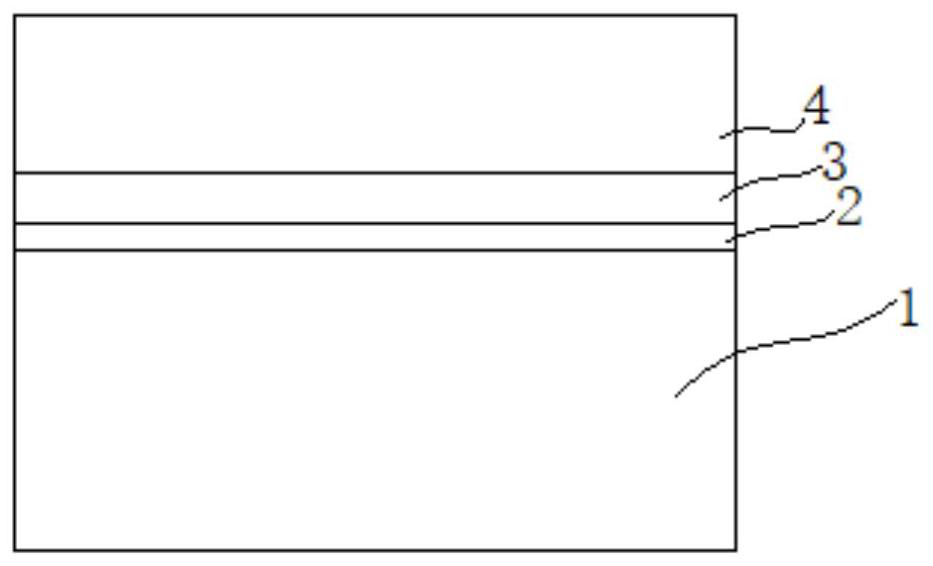

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

[0028] A kind of Al for copper interconnection wire 2 o 3 / ZrN bilayer diffusion barrier preparation method, comprising the following steps:

[0029] Step 1), the substrate is cleaned and pretreated; specifically, the substrate is sequentially placed in acetone and ethanol for ultrasonic cleaning, and then soaked in HF solution to remove the oxide layer on the surface of the substrate to remove organic pollution on the surface of the silicon chip material to improve the binding force of the membrane base; where the concentration of acetone solution is greater than 99.9%; the concentration of ethanol solution is greater than 99.9%, and finally 5% HF solution is used to remove the oxide layer on the surface.

[0030] Step 2), preparing a layer of Al on the surface of the substrate after cleaning and pretreatment 2 o 3 transition layer;

[0031] Specifically, the at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com