Building plywood formwork construction method based on BIM technology and intelligent system

A construction method and plywood technology, applied in data processing applications, forecasting, geometric CAD, etc., can solve the problems of difficult removal of wood chips on the construction site, on-site environmental pollution, and error-prone problems, so as to improve the level of collaborative management, improve the construction environment, The effect of reducing capital occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

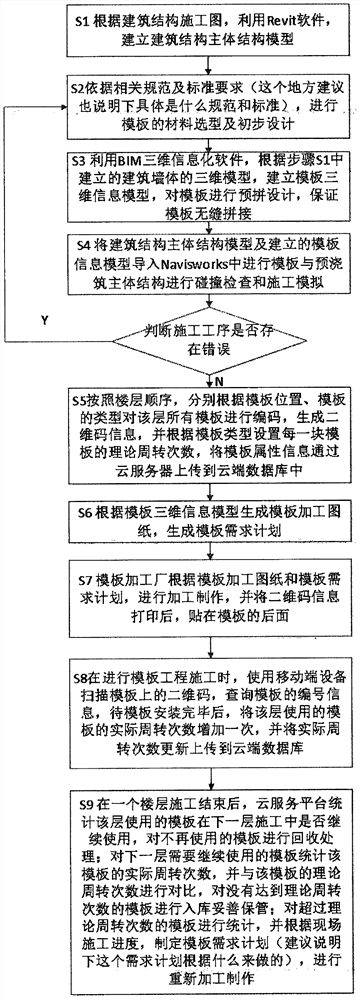

[0055] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings. Such as figure 1 As shown, the present invention provides a kind of plywood template construction method based on BIM technology, comprises the following steps:

[0056] In order to achieve the above object, the present invention provides a construction method of building plywood formwork based on BIM technology, comprising the following steps:

[0057] S1 According to the construction drawing of the building structure, use Revit software to establish the main structure model of the building structure;

[0058] S2 Carry out the material selection and preliminary design of the formwork according to the relevant specifications and standard requirements;

[0059] S3 uses BIM three-dimensional information software, according to the three-dimensional model of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com