Device for preparing polarization-maintaining fiber array and method of using the same

A polarization-maintaining optical fiber and array technology, which is applied in the coupling of optical waveguides, light guides, optics, etc., can solve the problem of the difficulty in accurately determining the center distance of the optical fiber array and the position of the polarization axis, the difficulty in ensuring the quality of the polarization-maintaining optical fiber array, and the inconvenient use, etc. problems, to achieve the effect of low production cost, precise center spacing and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

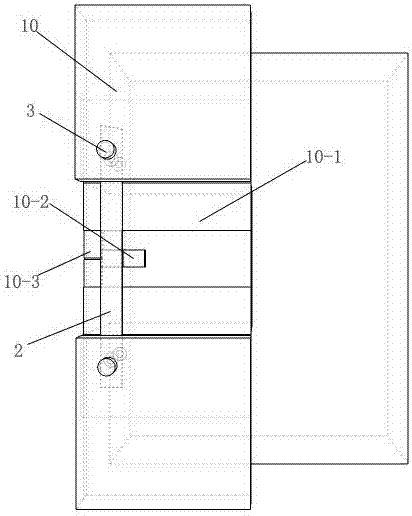

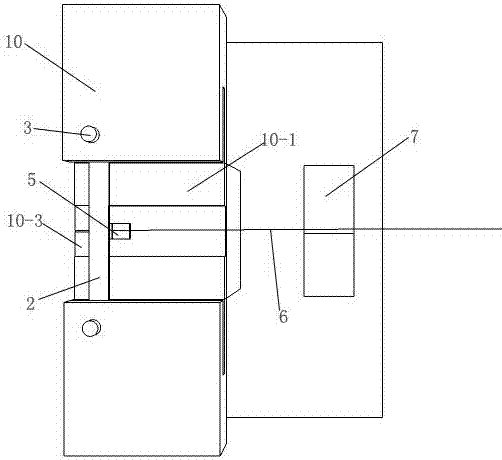

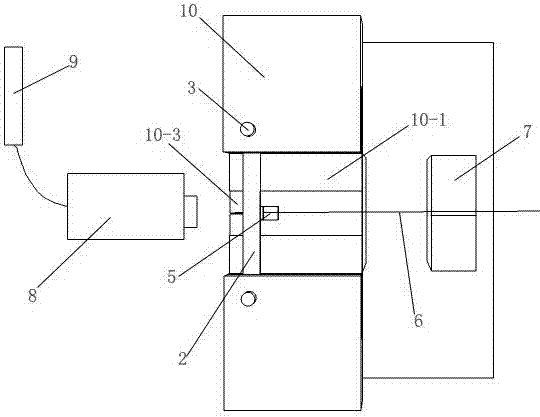

[0036] Such as Figure 1-7 As shown, a device for preparing a polarization-maintaining optical fiber array includes a fixture 10, foam 7, a manual rotating stage (shown in the figure), a microscope I8 and a microscope II11, the fixture 10 and the manual rotating stage are arranged oppositely, and the foam 7 Located between the jig 10 and the manual rotary table, several gaps are provided on the foam 7; a V-groove substrate 5 is installed on the jig 10, and several V-grooves corresponding to the gaps are arranged on the V-groove substrate 5; the microscope I8 is arranged in front of the V-groove substrate 5 and the optical axis of the microscope I8 is parallel to the V-groove. The microscope II11 is arranged above the V-groove substrate 5 and the optical axis of the microscope II11 is perpendicular to the V-groove.

[0037] The V-groove substrate 5 includes a substrate body, the substrate body is a two-level stepped structure, including a first-level step 5-1 and a second-level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com