Resourceful treatment device and process for mother liquor of reaction between waste incineration fly ash and hydrochloric acid

A technology for waste incineration fly ash and treatment process, which is applied in the directions of alkali metal chloride, calcium/strontium/barium halide, calcium/strontium/barium chloride, etc. Stability, high energy consumption, to achieve the effect of zero discharge of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

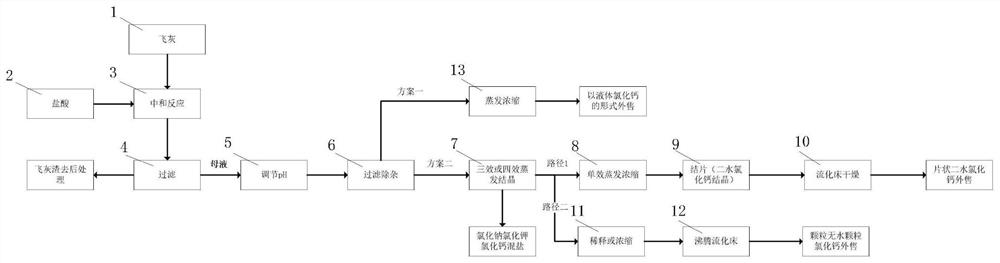

[0068] Embodiment 1, a kind of waste incineration fly ash and hydrochloric acid reaction mother liquor resource processing device, such as figure 1 As shown, it includes a fly ash storage tank 1, a hydrochloric acid storage tank 2, a neutralization reactor 3, a first filter device 4, a ph adjustment device 5, a second filter device 6, an evaporation crystallization device 7, a first evaporation concentration device 8, Sheeting device 9, drying device 10, dilution device 11, boiling granulation device 12 and second evaporative concentration device 13;

[0069] The fly ash storage tank 1 is used for storing waste incineration fly ash;

[0070] The hydrochloric acid storage tank 2 is used to store hydrochloric acid;

[0071] The neutralization reactor 3 is used for the neutralization reaction of fly ash and hydrochloric acid;

[0072] The first filter device 4 and the second filter device 6 are used to filter the solution;

[0073] The pH adjusting device 5 is used to adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com