Zero-emission recycling device for water paper or raw cement board papermaking wastewater

A paper-making wastewater and zero-discharge technology, which is applied in the direction of processing wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems that sediment cannot be reused, there are many unit facilities, and there are many processes. , to achieve the effects of environmental protection, pollution avoidance and zero discharge of waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

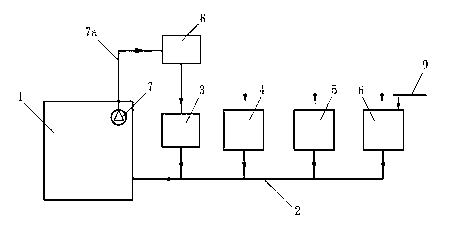

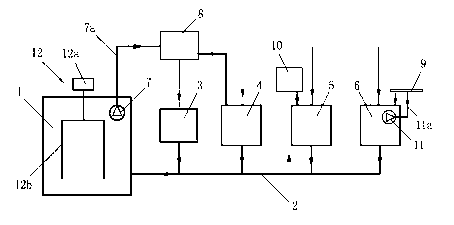

[0030] See attached figure 1 , figure 2 .

[0031] A total waste water collection pool 1 and a waste water delivery component 2 are provided, and the outlet of the waste water delivery component 2 communicates with the total waste water collection pool.

[0032] A pulping waste water tank 3 is provided, and the outlet of the pulping waste water tank is communicated with the waste water conveying member 2, that is, the waste water with a higher concentration in the pulping waste water tank flows into the total waste water collecting tank 1 by the waste water conveying member 2, which is higher than the concentration in the pond. Low wastewater mixing; the bottom elevation of the pulping wastewater tank is preferably higher than the total wastewater collection tank 1, so that the wastewater and sediment in the pulping wastewater tank enter the total wastewater collection tank in an artesian state.

[0033] A screening waste water pool 4 is provided, and the outlet of the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com