Sugar-free weeping forsythia leaf granules as well as preparation method and application thereof

A technique for forsythia leaves and granules, which is applied in the field of sugar-free forsythia granules and its preparation, can solve the problems of side effects, high price, complicated preparation process, severe liver damage, etc., and achieves convenience in taking, simple preparation process, store simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] [Example 1] Preparation and granulation of forsythia leaf water extract

[0030] S1. Weigh forsythia leaves, add distilled water to heat and reflux to extract, filter, combine the filtrate, and concentrate to a certain ratio to obtain a concentrated solution, such as figure 1 shown, or dry the concentrate to obtain a concentrated dry powder, such as figure 2 shown;

[0031] S2. After the concentrated solution is mixed with auxiliary materials and aspartame, wet granulation is performed, or after the concentrated liquid dry powder is mixed with auxiliary materials and aspartame, an appropriate amount of ethanol solution is added for wet granulation;

[0032] S3. The prepared granules are sieved and dried to obtain Forsythia leaf weight-loss granules, such as Figure 8 shown;

[0033] Among them, in S1, forsythia leaves are fresh forsythia leaves or dried forsythia leaves, distilled water is added 0.5-30 times, extraction times are 1-3 times, extraction time is 0.5-3 ...

Embodiment 2

[0036] [Example 2] Preparation and granulation of Forsythia leaf ethanol solution (concentration is 0-100%) extract

[0037] S1. Weigh forsythia leaves, add ethanol aqueous solution to heat and reflux to extract, filter, combine filtrates, and concentrate to a certain ratio to obtain a concentrated solution or dry the concentrated solution to obtain a concentrated dry powder;

[0038] S2. After the concentrated solution is mixed with auxiliary materials and aspartame, wet granulation is performed, or after the concentrated liquid dry powder is mixed with auxiliary materials and aspartame, an appropriate amount of ethanol solution is added for wet granulation;

[0039] S3. The prepared granules are sieved and dried to obtain the forsythia leaf weight-loss granules;

[0040] Wherein, in S1, the Forsythia leaves are fresh Forsythia leaves or dried Forsythia leaves, add 0.5-30 times of ethanol aqueous solution, the concentration of ethanol aqueous solution is 0-100% by weight, the...

Embodiment 3

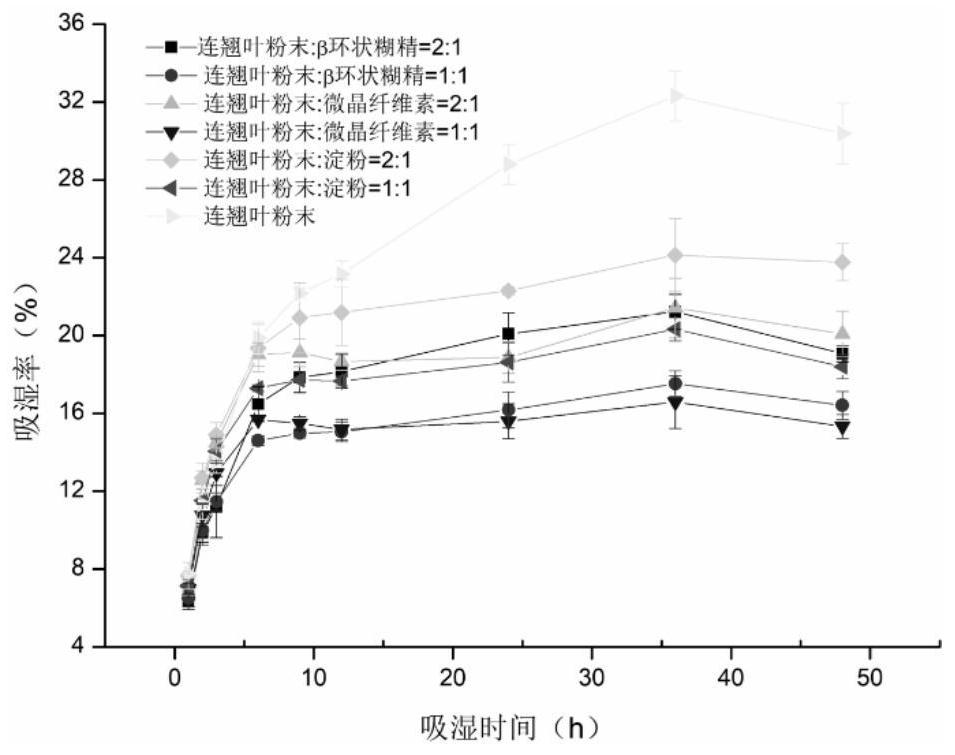

[0043] [Example 3] Screening of granule auxiliary materials

[0044] Forsythia leaf extract has high viscosity, strong hygroscopicity, and is easy to agglomerate. The soft material is wet and soft when directly granulated, and the molding rate is low. In order to reduce its hygroscopicity and make it easier to granulate, it is necessary to add appropriate amount of excipients to improve it. Choose excipients commonly used in sugar-free granules, which are helpful for granule formation, dissolution and low hygroscopicity. Therefore, soluble starch, maltodextrin, and β-ring Common excipients such as dextrin and microcrystalline cellulose were compared and screened. The above excipients and forsythia leaf extract were granulated in different proportions and in different combinations, and then placed in an oven at 40°C for 30 minutes to fully dry the granules, and spread them flat on the bottom of a weighing bottle with a constant weight, with a thickness of about 2mm. Weigh it, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com