Cooling and dewatering device for automobile exhaust pipe

A technology for automobile exhaust and exhaust pipes, which is applied in the direction of exhaust devices, mufflers, engine components, etc., which can solve the problems of poor exhaust cooling effect and exhaust pipe blockage, and achieve a good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

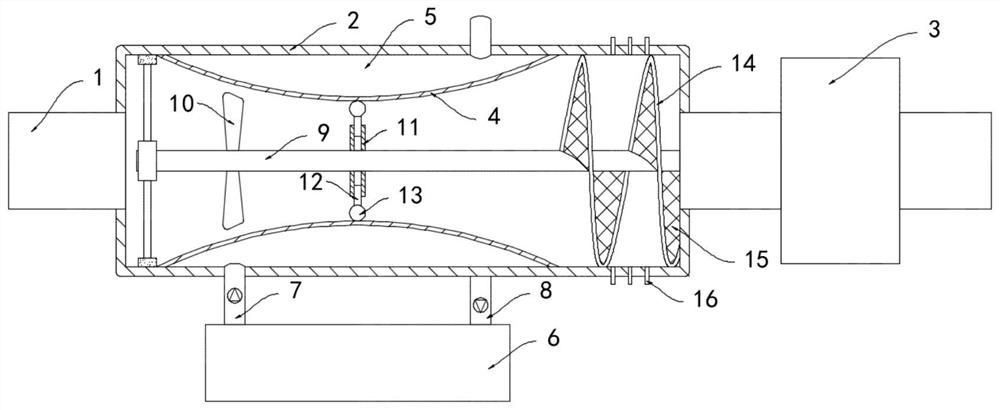

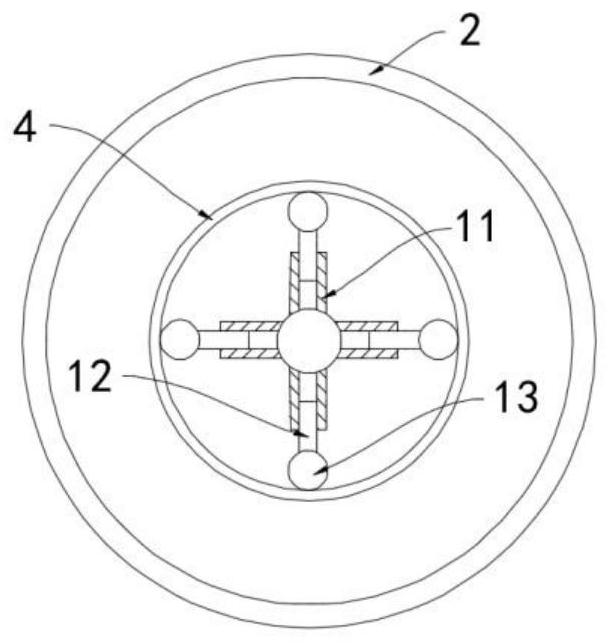

[0016] Such as Figure 1-2 As shown, a cooling and dewatering device for an automobile exhaust pipe includes an exhaust pipe 1, and the exhaust pipe 1 is sequentially connected with a cooling box 2 and a purification muffler 3, and the cooling box 2 is arranged coaxially with the exhaust pipe 1. The cylindrical structure, the inner wall of the cooling box 2 is equipped with a deformation tube 4, both ends of the deformation tube 4 are fixed and sealed with the inner wall of the cooling box 2, the section of the deformation tube 4 is dumbbell-shaped and connected to the A coolant cavity 5 is formed between them, and a return box 6 is provided outside the cooling box 2, and the return box 6 communicates with the coolant cavity 5 through a one-way liquid inlet pipe 7 and a one-way liquid discharge pipe 8, and a cooling box 2 is provided along its axis. The rotating shaft 9 extending in the direction, the fan 10 is installed coaxially outside the rotating shaft 9, and a plurality ...

Embodiment 2

[0021] Such as Figure 1-2 As shown, the difference between this embodiment and Embodiment 1 is that: the weight ball 13 is made of magnetic material, and the spring 14 is an electromagnetic spring.

[0022] In this embodiment, according to the principle of electromagnetic induction, when the magnetic flux in the closed coil changes, an induced current will be generated in the closed coil, and when the weight ball 13 rotates with the rotating shaft 9, the magnetic flux in the spring 14 will change, resulting in Induce current and generate an induced magnetic field, and each coil of the electromagnetic spring 14 produces a small magnetic coil with the same magnetic pole, and under the action of the induced magnetic field, the electromagnetic spring 14 is driven to shrink, thereby driving the water filter net 15 to shrink, further improving the moisture absorption in the exhaust gas. After the counterweight ball 13 stops rotating, the induced magnetic field in the spring 14 disa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com