Silicon carbide ceramic membrane and preparation method and application thereof

A technology of silicon carbide and ceramic membranes, applied in ceramic products, chemical instruments and methods, applications, etc., can solve problems such as cracking of membrane layers, energy waste, shedding, etc., achieve energy saving, simple and not cumbersome process flow, and avoid multiple times The effect of transshipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A silicon carbide ceramic membrane, including a support body and a film layer connected to the support body;

[0031] The support body includes the following raw materials in parts by weight: 85 parts of silicon carbide; 6 parts of pore-forming agent; 8 parts of firing binder; 3 parts of forming aid; the pore-forming agent is activated carbon or walnut shell powder ; The molding aid is a thermosetting phenolic resin.

[0032] The film layer includes the following raw materials in parts by weight: 70 parts of corundum sand, 10 parts of firing binder, 10 parts of pore-forming agent, 38 parts of water, 0.1 part of dispersant, and 0.1 part of suspending agent;

[0033] Wherein: sintering binder, in parts by weight, includes: 76 parts of Zhangcun soil, 5 parts of dolomite, 3 parts of glass fiber powder.

[0034] The support body and the film layer are fired once and have several through holes, the diameter of the through holes is 30-33 μm, and the pressure difference on bot...

Embodiment 2

[0036] A silicon carbide ceramic membrane, including a support body and a film layer connected to the support body;

[0037] The support body includes the following raw materials in parts by weight: 92 parts of silicon carbide; 10 parts of pore-forming agent; 15 parts of firing binder; 8 parts of forming aid; the pore-forming agent is activated carbon or walnut shell powder ; The molding aid is a thermosetting phenolic resin.

[0038] The film layer includes the following raw materials in parts by weight: 90 parts of corundum sand, 30 parts of firing binder, 20 parts of pore-forming agent, 50 parts of water, 0.3 part of dispersant, and 0.3 part of suspending agent;

[0039] Wherein: sintering binder, in parts by weight, includes: 96 parts of Zhangcun soil, 16 parts of dolomite, and 16 parts of glass fiber powder.

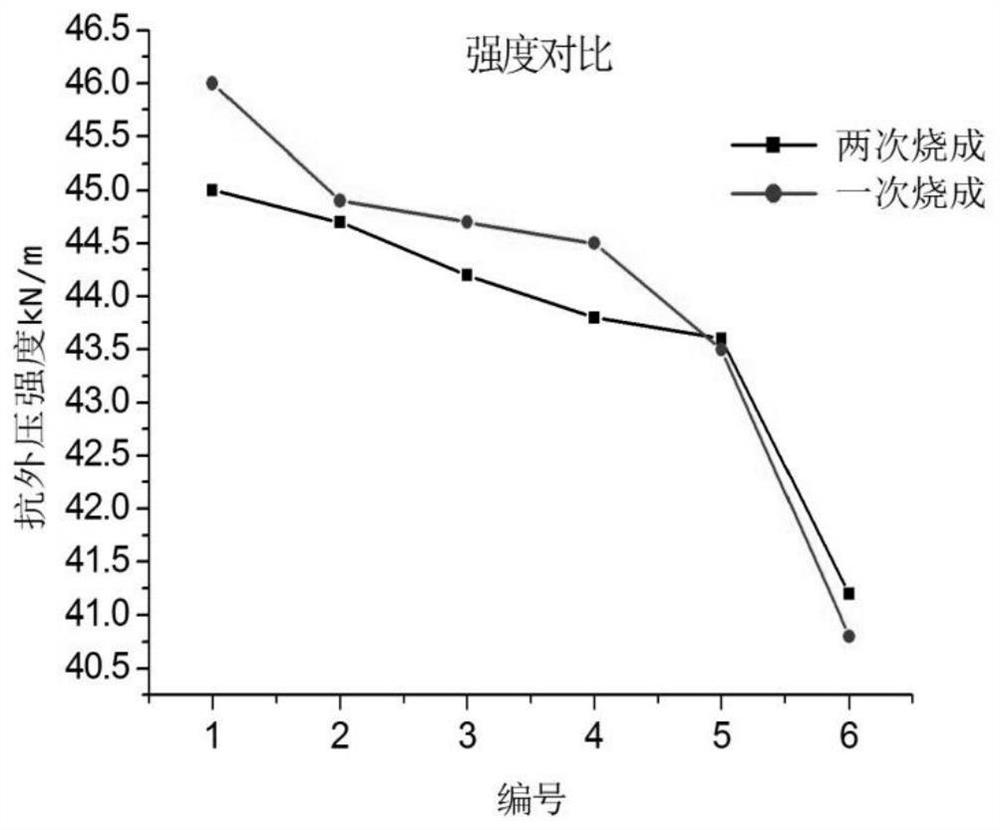

[0040] Silicon carbide is selected as the support body aggregate, and a sintered binder is added to make it have better high temperature stability and a lower ther...

Embodiment 3

[0043] A silicon carbide ceramic membrane, including a support body and a film layer connected to the support body;

[0044] The support body includes the following raw materials in parts by weight: 90 parts of silicon carbide; 8 parts of pore-forming agent; 12 parts of firing binder; 5 parts of forming aid; the pore-forming agent is activated carbon or walnut shell powder ; The molding aid is a thermosetting phenolic resin.

[0045] The film layer includes the following raw materials in parts by weight: 80 parts of corundum sand, 20 parts of firing binder, 15 parts of pore-forming agent, 42 parts of water, 0.2 part of dispersant, and 0.2 part of suspending agent;

[0046] Wherein: firing binder, by weight parts, comprises: 86 parts of Zhangcun soil, 8 parts of dolomite, 6 parts of glass fiber powder.

[0047] The support body and the film layer are fired once and have several through holes, the diameter of the through holes is 30-33 μm, and the pressure difference on both si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com