Solid electrolyte, composite integrated positive electrode, integrated battery and preparation method thereof

A solid electrolyte and electrolyte technology, which is applied in the field of solid electrolyte, composite integrated positive electrode, integrated battery and its preparation, can solve the problems of unstable CNT attachment and easy drop, and achieve simple and easy processing methods, excellent stability, The effect of increasing the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention provides a method for preparing a solid electrolyte, which is prepared by a high-temperature solid phase pre-firing-firing two-step method, including the following steps:

[0040] S1. Disperse powdered lithium hydroxide, lanthanum trioxide, zirconium dioxide and tantalum pentoxide in isopropanol according to a predetermined ratio, and ball mill for 8 to 12 hours at a speed of 300 to 400 rpm to obtain a slurry ; Then, vacuum-dry the ground slurry at 70-90°C for 10-15 hours to obtain a mixed powder;

[0041] S2, pre-firing the mixed powder prepared in step S1 at 940-960° C. for 4-8 hours to obtain a pre-fired powder, and then grinding the pre-fired powder;

[0042] S3, firing the calcined powder after the grinding treatment in step S2 at 1050-1150° C. for 12-16 hours to obtain the solid electrolyte.

[0043] As a further improvement of the present invention, the mass ratio of lithium hydroxide, lanthanum trioxide, zirconium dioxide and tantalum pent...

Embodiment 1

[0053] 1. Solid electrolyte Li 6.7 La 3 Zr 1.7 Ta 0.3 o 12 Synthesis of (LLZTO):

[0054] It is prepared by high-temperature solid phase pre-firing-firing two-step method, including the following steps:

[0055] S1, according to the mass ratio of 0.36:1:0.43:0.14, put powdered lithium hydroxide, lanthanum trioxide, zirconium dioxide and tantalum pentoxide into an agate ball mill jar, use isopropanol as the dispersion liquid, At 350 rpm, ball milling for 10 hours to obtain a slurry; then, put the ground slurry in a vacuum oven at 80° C. for 12 hours to obtain a mixed powder;

[0056] S2, placing the mixed powder prepared in step S1 in a corundum crucible, pre-firing at 950° C. for 6 hours (air atmosphere) to obtain a pre-fired powder, and then grinding the pre-fired powder;

[0057] S3, firing the pre-fired powder after the grinding treatment in step S2 at 1100° C. for 14 hours to obtain LLZTO powder, which is the solid electrolyte.

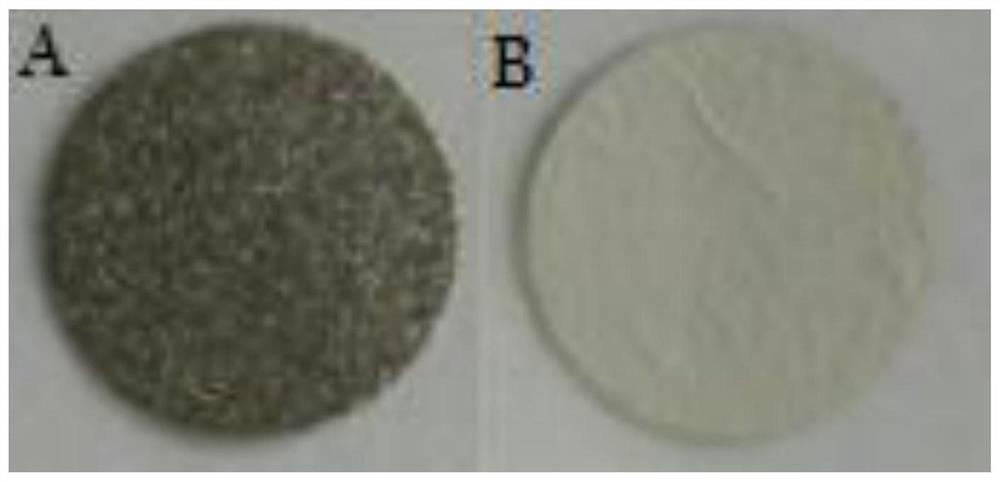

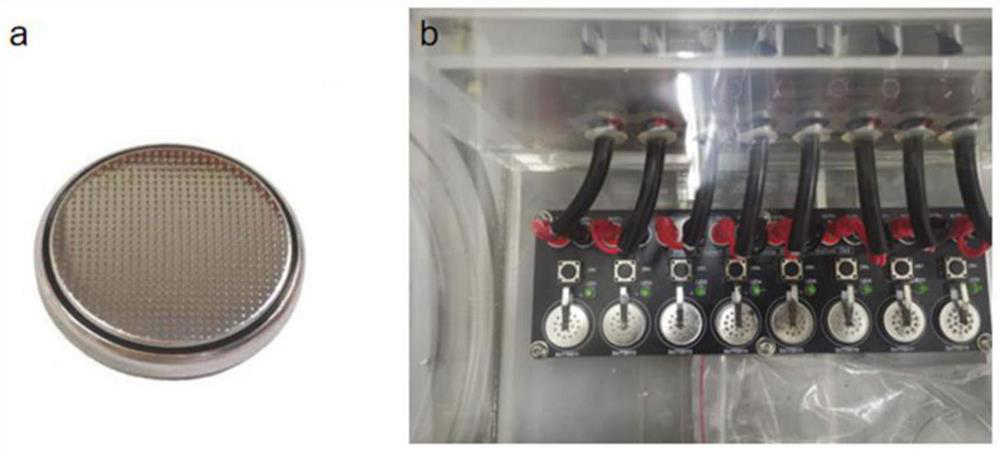

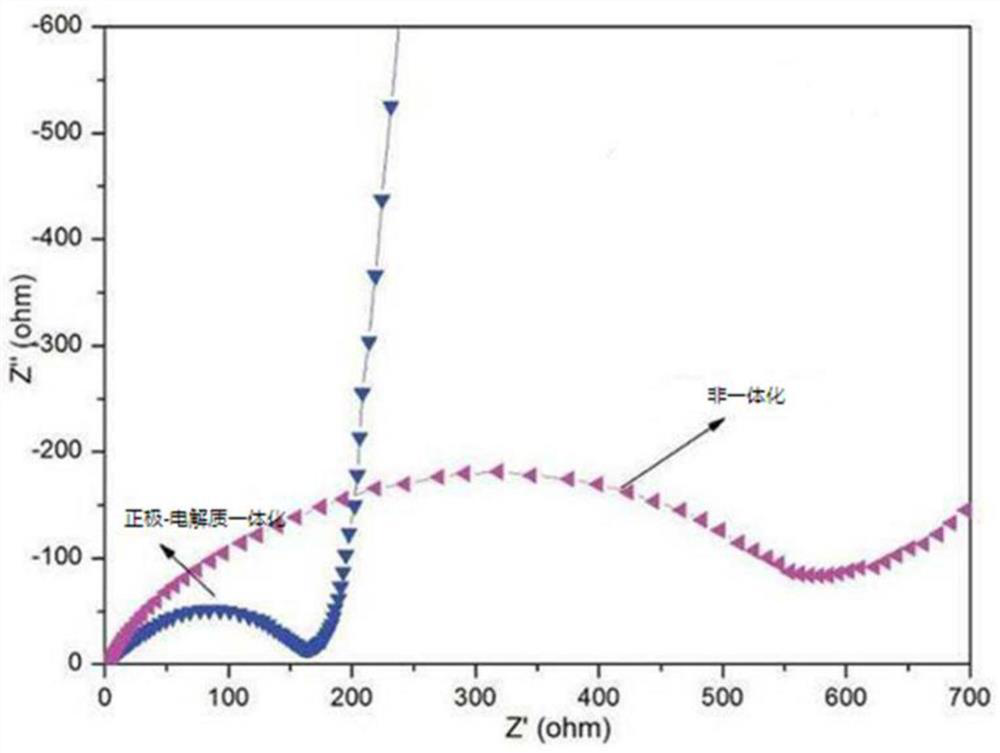

[0058] 2. Preparation of LLZTO / PVDF ...

Embodiment 2-3

[0091] The difference from Example 1 is that in the LLZTO / PVDF composite polymer electrolyte membrane, the mass ratio of LLZTO and PVDF is different, and other steps are the same as in Example 1, and will not be repeated here.

[0092] Table 2 is the process parameter setting and performance parameter in embodiment 1-3

[0093] Example Mass ratio of LLZTO and PVDF Conductivity Example 1 12:5.14 6.4×10 -4 S cm -1

[0094] It can be seen from Table 2 that the effect of the mass ratio of LLZTO and PVDF on the conductivity of the composite polymer electrolyte membrane is: the higher the relative content of LLZTO, the higher the conductivity will be, but when it increases to a certain value (the mass ratio of LLZTO and PVDF is about 12:5.14), the conductivity increase is not obvious.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com