Method for treating phenol-based residues of rectifying still

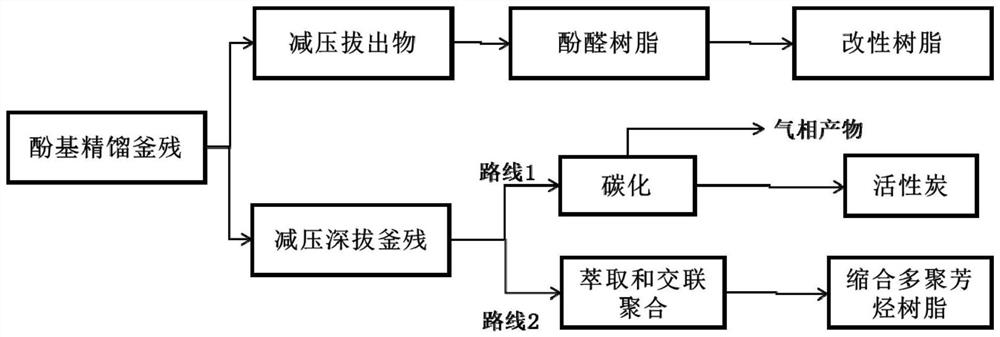

A treatment method and rectification kettle technology, applied in the field of environmental protection and solid waste treatment, can solve the problems of long time required, air pollution, groundwater pollution, etc., achieve better resin performance and improve adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0148] The present embodiment provides a kind of treatment method of phenol-based rectification still residue, and described treatment method comprises the following steps:

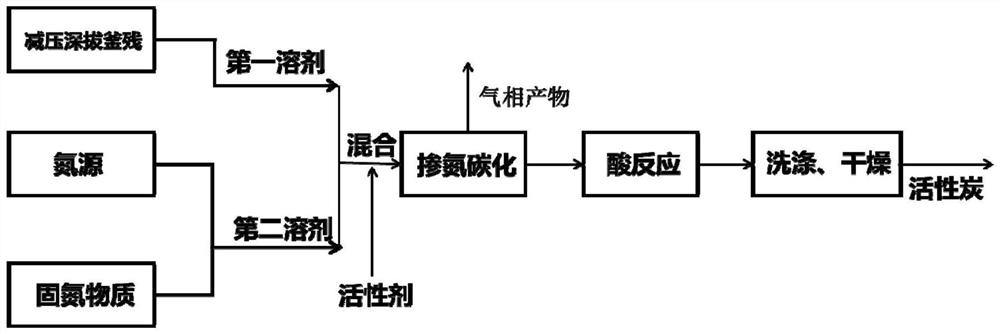

[0149] (1) The residue of a phenol-based rectification kettle in a factory in Yunnan was subjected to deep vacuum extraction to obtain a deep-drawn vacuum extract with a tower top temperature of 180°C at 5kPa and a vacuum deep-draw kettle residue with a tower tank temperature of 300°C ;

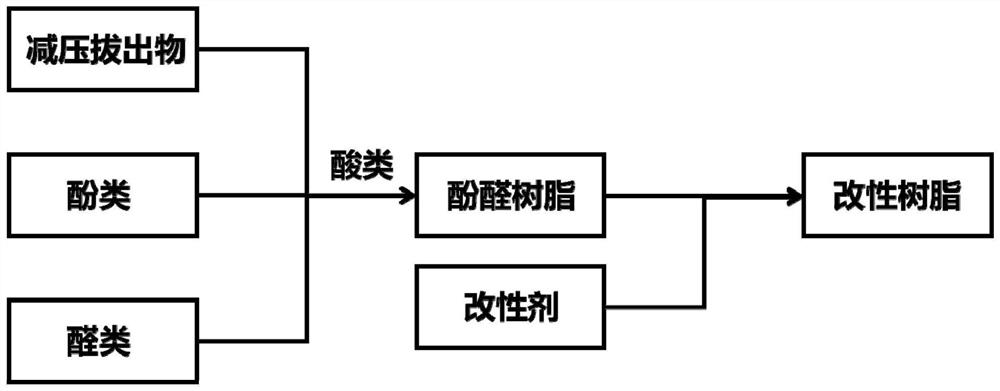

[0150] (2) The decompression extract, phenol, formaldehyde and half of the total amount of oxalic acid in the mixing step (1) (the mass ratio of the phenol to the decompression extract is 2.8:1; the molar ratio of the formaldehyde to phenol The ratio is 0.73:1; the total amount of oxalic acid accounts for 3.2wt% of the material extracted under reduced pressure), heated to reflux for the first-stage reaction for 0.5h, then added the remaining half of the oxalic acid again, carried out the second-stage reaction for 1h, add...

Embodiment 2

[0156] This embodiment provides a treatment method for phenol-based rectification still residue. The treatment method is the same as in Example 1 except that ferrocene is not added in step (2).

Embodiment 3

[0158] This embodiment provides a treatment method for phenol-based rectification still residue. The treatment method is the same as in Example 1 except that ammonium polyphosphate is not added in step (3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| carbon residual rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com