Activated carbon material applied to supercapacitor electrode material

A technology of supercapacitors and electrode materials, applied in hybrid capacitor electrodes, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as low utilization rate of specific surface area, and achieve uniform and controllable pore size, uniform pore size distribution, and less ash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

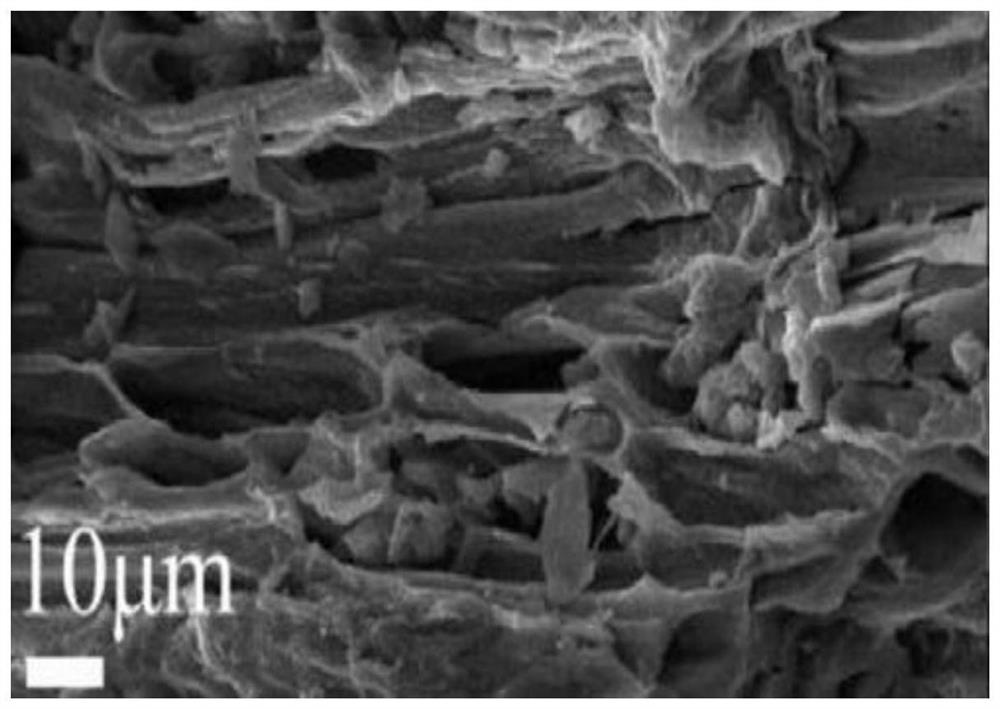

Image

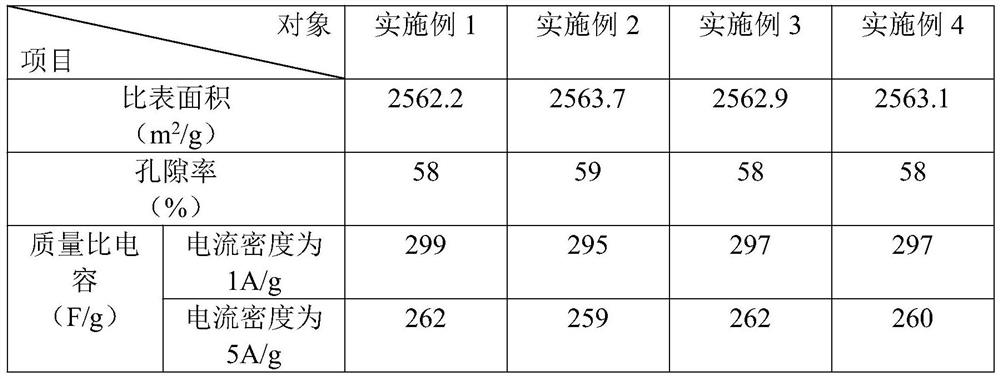

Examples

Embodiment 1

[0026] An activated carbon material applied to supercapacitor electrode materials, specifically comprising the steps of:

[0027] S1: Pretreatment methods for cotton stalks include:

[0028] 1) Wash the cotton stalks with distilled water, then dry them at 100°C for 10 hours, and then grind them through a 100-mesh sieve for use in the next step.

[0029] 2) Soak the cotton stalk fragments in step 1) in 5mol / L sodium hydroxide solution for 2h, then filter and wash to neutrality, then soak in 4wt% acetic acid solution for 5h, filter and wash at 100 It was dried at ℃ for 3h and used in the next step.

[0030] 3) Mix and grind the cotton stalk powder and chitosan obtained in step 2), wherein the mass ratio of cotton stalk powder and chitosan is 1:0.14, and then place it in a tube furnace in a nitrogen atmosphere at 500°C Roasting for 5 hours, cooling and grinding through a 160-mesh sieve to obtain cotton straw powder.

[0031] S2: The pretreatment methods of bamboo chips include...

Embodiment 2

[0041]An activated carbon material applied to supercapacitor electrode materials, specifically comprising the steps of:

[0042] S1: Pretreatment methods for cotton stalks include:

[0043] 1) Wash the cotton stalks with distilled water, then dry them at 100°C for 11 hours, and then grind them through a 100-mesh sieve for use in the next step.

[0044] 2) Soak the cotton stalk fragments in step 1) in 5mol / L sodium hydroxide solution for 3h, then filter and wash to neutrality, then soak in 8wt% acetic acid solution for 6h, filter and wash at 100 It was dried at ℃ for 5h and used in the next step.

[0045] 3) Mix and grind the cotton stalk powder and chitosan obtained in step 2), wherein the mass ratio of cotton stalk powder and chitosan is 1:0.17, and then place it in a tube furnace in a nitrogen atmosphere at 520°C Roasting for 8 hours, cooling and grinding through a 160-mesh sieve to obtain cotton straw powder.

[0046] S2: The pretreatment methods of bamboo chips include:...

Embodiment 3

[0056] An activated carbon material applied to supercapacitor electrode materials, specifically comprising the steps of:

[0057] S1: Pretreatment methods for cotton stalks include:

[0058] 1) Wash the cotton stalks with distilled water, then dry them at 100°C for 10 hours, and then grind them through a 100-mesh sieve for use in the next step.

[0059] 2) Soak the minced cotton stalks in step 1) in 5 mol / L sodium hydroxide solution for 2.5 hours, then filter and wash until neutral, then soak in 6 wt% acetic acid solution for 5.5 hours, filter and wash, Dry at 100°C for 4h and prepare for use in the next step.

[0060] 3) Mix and grind the cotton stalk powder and chitosan obtained in step 2), wherein the mass ratio of cotton stalk powder and chitosan is 1:0.15, and then place it in a tube furnace under a nitrogen atmosphere at 510°C Roasting for 6 hours, cooling and grinding through a 160-mesh sieve to obtain cotton straw powder.

[0061] S2: The pretreatment methods of bam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com