A polymer-assisted separation method for large-diameter semiconducting single-walled carbon nanotubes

A single-walled carbon nanotube and semiconducting technology, which is applied in the field of polymer-assisted separation of large-diameter semiconducting single-walled carbon nanotubes, can solve problems such as difficult separation, achieve simple operation, good industrial application prospects, and less time-consuming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

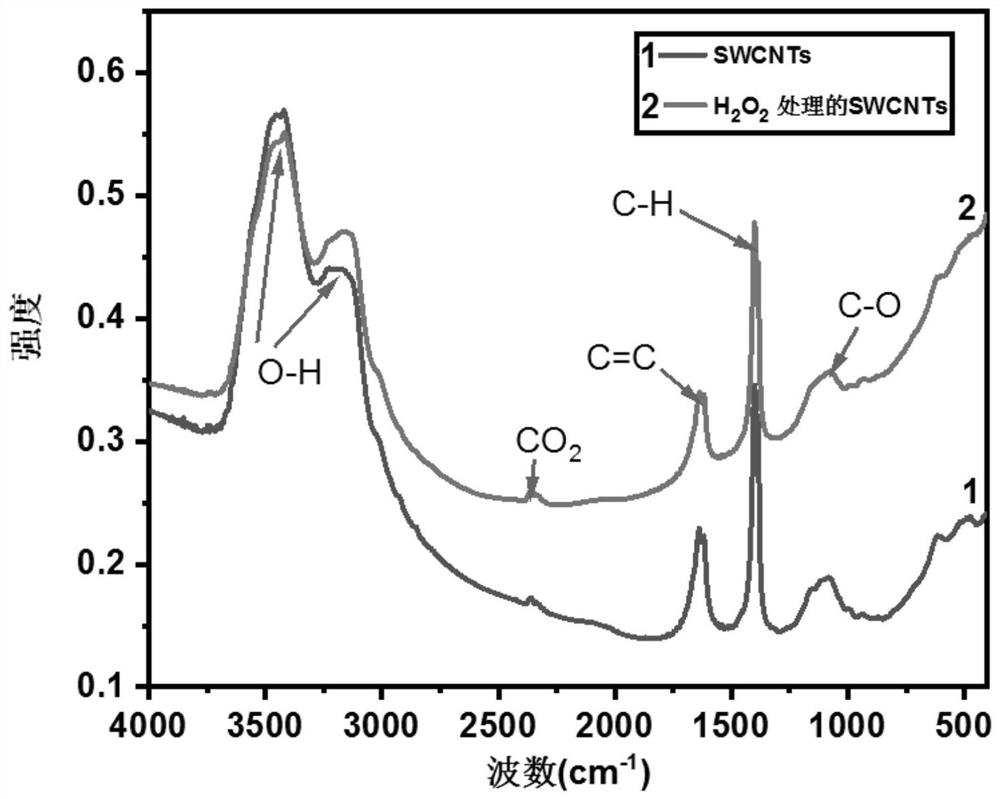

[0038] In this embodiment, step (1) is used to process 100 mg of large-diameter single-walled carbon nanotubes, wherein the concentration of the aqueous hydrogen peroxide solution is analytically pure, and the processing time is 72 hours. like figure 1 As shown, the infrared absorption spectrum shows that no C=O bond was detected in the samples before and after the treatment with the aqueous hydrogen peroxide solution, indicating that the oxidation of hydrogen peroxide to single-walled carbon nanotubes at room temperature is very weak.

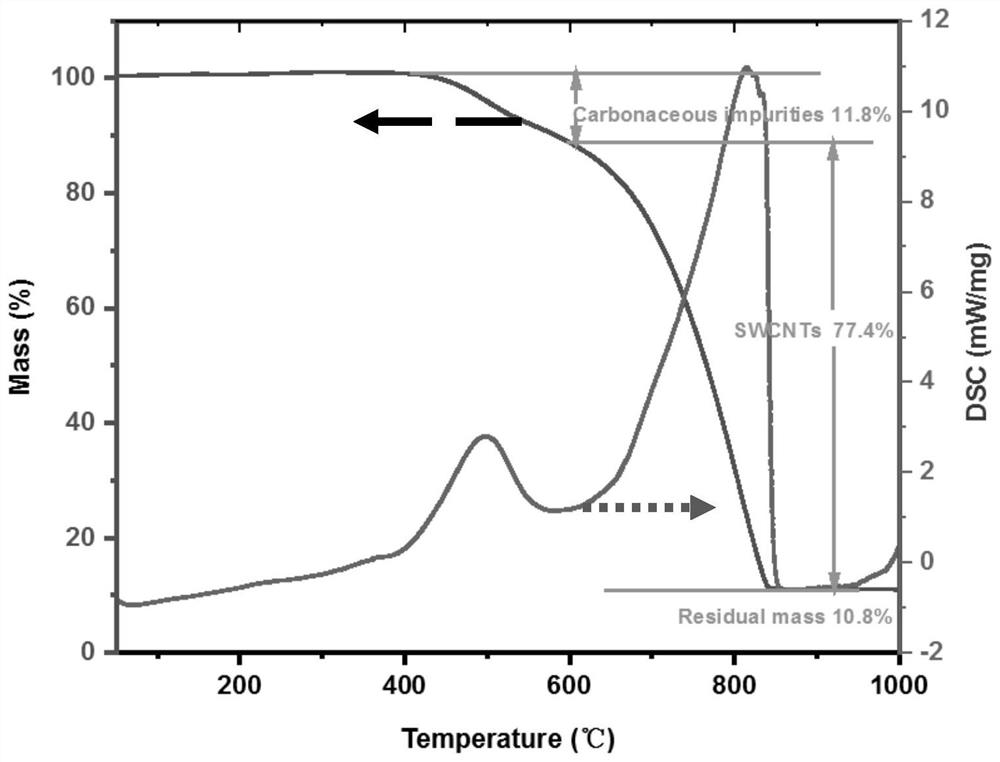

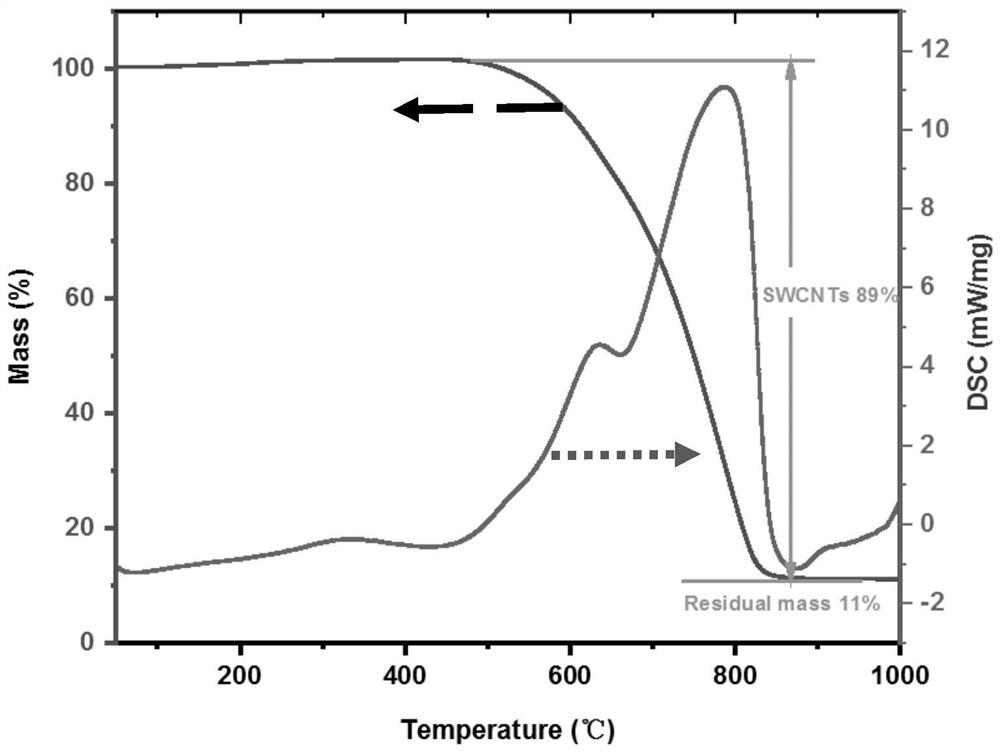

[0039] like figure 2 and image 3 As shown, the thermogravimetric / differential thermal analysis curves of single-walled carbon nanotubes before and after hydrogen peroxide treatment show that the content of carbon impurities in single-walled carbon nanotubes after hydrogen peroxide treatment is greatly reduced, indicating that hydrogen peroxide aqueous solution has a strong effect on amorphous carbon. and other impurities have a strong oxid...

Embodiment 2

[0045] 100 mg of large-diameter single-walled carbon nanotubes were treated by step (1), wherein the concentration of the aqueous hydrogen peroxide solution was analytically pure, and the treatment time was 72 h. The infrared absorption spectrum showed that no C=O bond was detected in the samples before and after the treatment with the aqueous solution of hydrogen peroxide, indicating that the oxidation of hydrogen peroxide to single-walled carbon nanotubes at room temperature was very weak. The thermogravimetric / differential thermal analysis curve shows that the content of carbon impurities in the single-walled carbon nanotubes is greatly reduced after hydrogen oxide treatment, indicating that the hydrogen peroxide aqueous solution has a strong oxidation effect on impurities such as amorphous carbon; Raman spectroscopy shows that hydrogen peroxide After the aqueous solution treatment, the G / D ratio of the samples decreased slightly compared with the pristine CNT samples, but w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com