Engineering high-efficiency counter-current chromatography equipment

A high-efficiency counter-current chromatography and engineering technology, applied in the field of counter-current chromatography equipment, to achieve high-efficiency counter-current chromatography separation and purification equipment, ensure reasonable and efficient, and improve the effect of distribution and separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

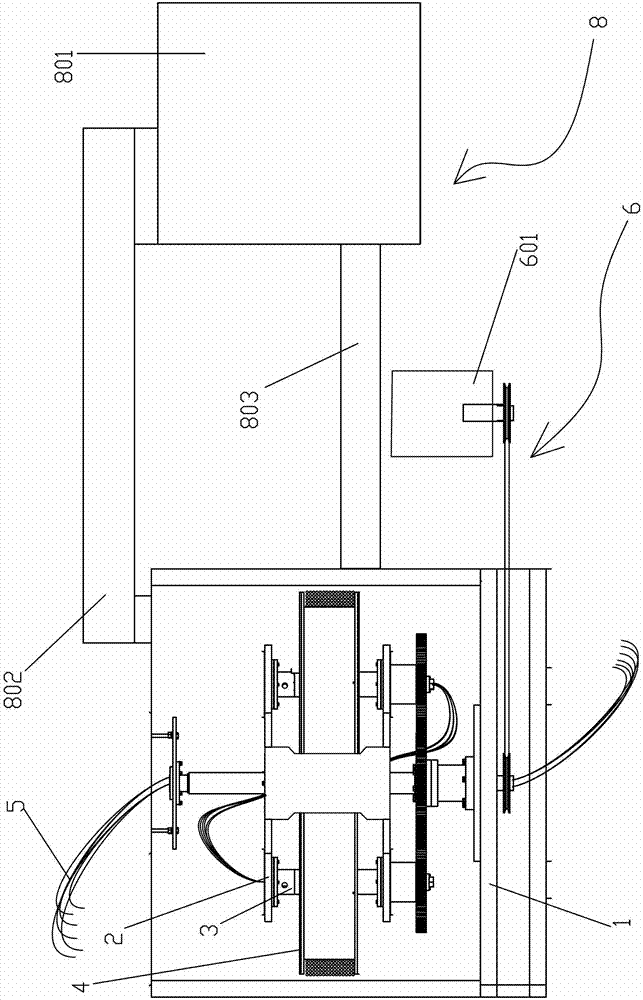

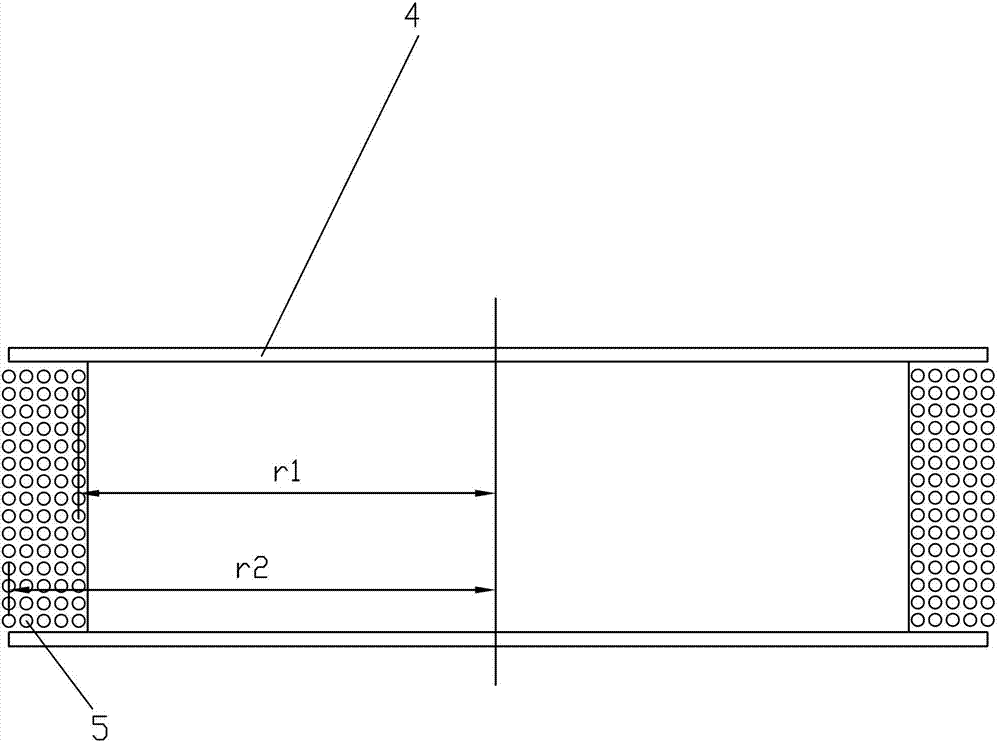

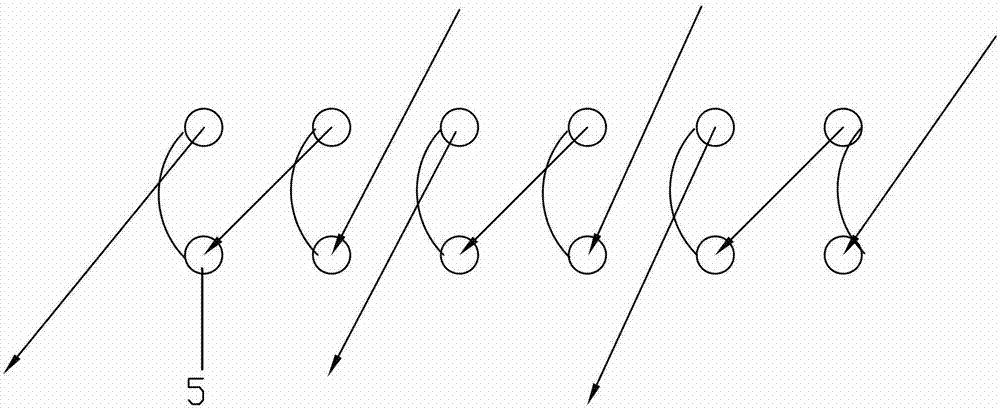

[0034] An engineered high-efficiency countercurrent chromatographic equipment, including a base 1, the base 1 is provided with a planet carrier 2 that can rotate relative to the base 1, and the planet carrier 2 is connected to drive the The drive device 6 for the rotation of the planet carrier 2, the planet carrier 2 is provided with a planet shaft 3, the planet shaft 3 is equipped with a planet wheel 4, and the planet wheel 4 is wound with a plurality of helically wound spiral separation In the pipe 5, the ratio of the winding radius r1 of the innermost spiral separation pipe 5 to the winding radius r2 of the outermost spiral separation pipe 5 is 0.85-1. In order to achieve a β value of 0.75 to 1, to achieve a high retention value.

[0035] There are 6 spiral separation tubes 5.

[0036] The 6 spiral tubes can be connected in any series and parallel, and each of the spiral separation tubes 5 is provided with connectors at both ends, and the spiral separation tubes 5 are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com