Meal replacement powder containing agriophyllum squarrosum as well as preparation method, edible method and application thereof

A technology of meal replacement powder and sandy rice powder, which is applied in the fields of application, food science, food ingredients, etc., can solve the problems of uneven quality, high starch content, and poor satiety, and achieve short crushing time, balanced nutritional components, and ripening short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention provides a preparation method of the meal replacement powder described in the above technical solution, comprising the following steps:

[0051] The sand rice, red bean, barley, quinoa and corn grits are respectively dried and matured in sequence to obtain ripe sand rice, cooked red bean, ripe barley, ripe quinoa and ripe corn grits;

[0052] Drying wolfberry and cistanche slices to obtain dried wolfberry and dried cistanche slices;

[0053] Grinding the ripened sand rice, ripened red bean, ripened barley, ripened quinoa, ripened corn grits, dried wolfberry, dried cistanche slices, oats, pumpkin seeds and sesame seeds respectively to obtain raw material powder;

[0054] The raw material powder is mixed with soybean protein isolate powder, whey protein powder, inulin powder, fried white kidney bean powder, konjac powder and perilla seed powder to obtain meal replacement powder.

[0055] In the present invention, sand rice, red bean, barley, quinoa ...

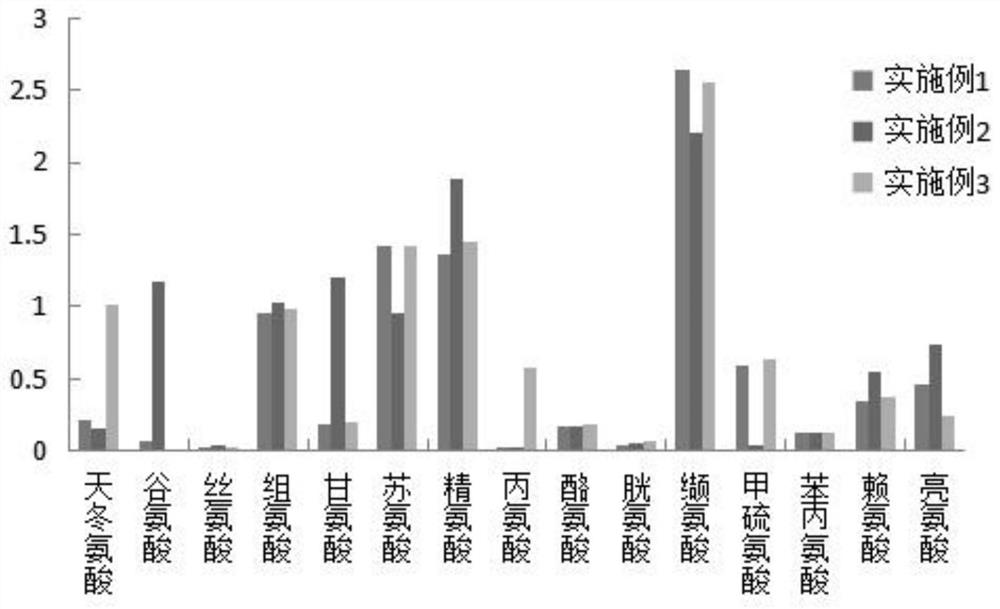

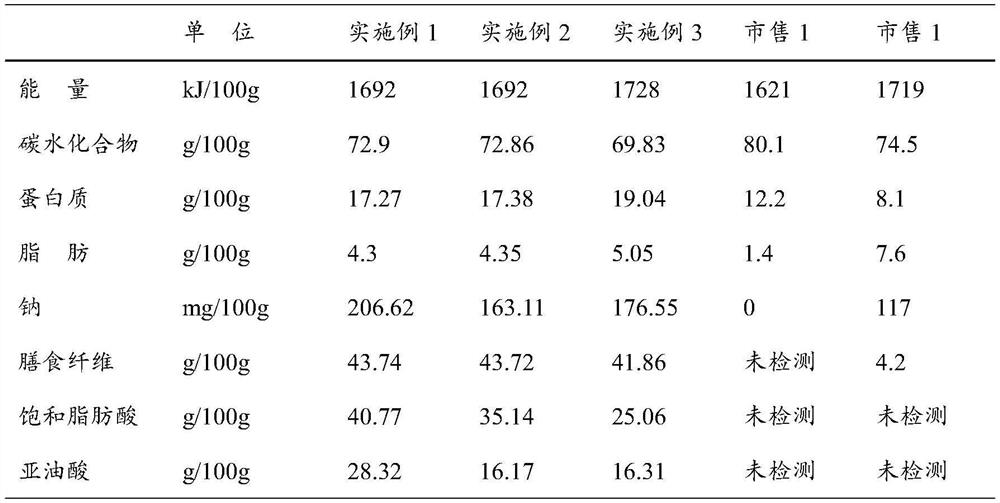

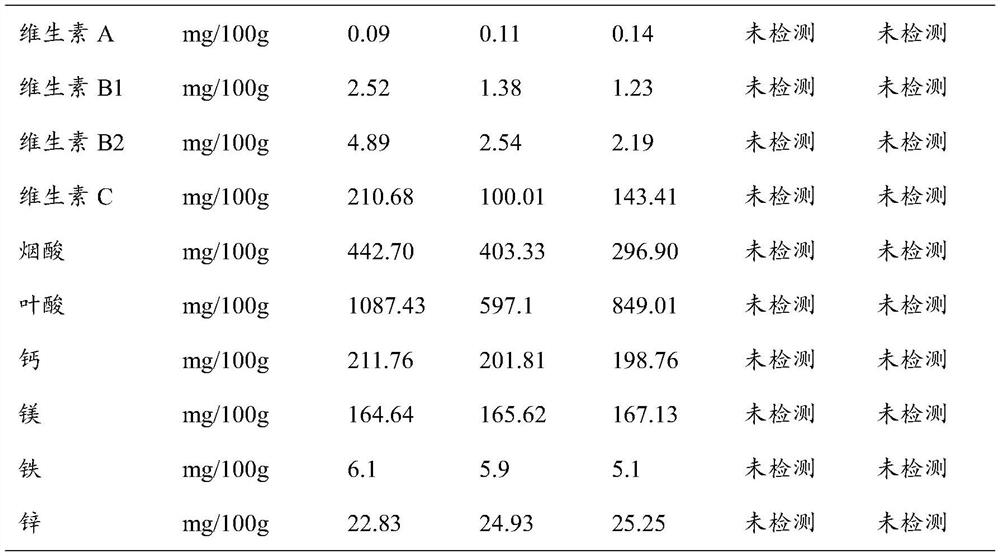

Embodiment 1

[0066] Prepare materials according to mass: 20 parts of sand rice flour, 12 parts of soybean protein isolate powder, 17 parts of whey protein powder, 5 parts of inulin powder, 4 parts of barley flour, 1.5 parts of red bean powder, 5 parts of fried white kidney bean powder, 4 parts of konjac powder , 5 parts of wolfberry powder, 4 parts of cistanche powder, 5 parts of oats, 8 parts of quinoa powder, 1 part of corn grits powder, 2 parts of perilla seed powder, 2 parts of pumpkin seeds, and 0.3 parts of sesame.

[0067] Its preparation includes the following steps:

[0068] Raw material pretreatment: select sand rice, red bean, barley, wolfberry, cistanche, oats, quinoa, and corn grits to remove stones, sand and imperfect grains, and put sand rice into the grain cleaning machine for screening: The aperture of the first layer of sieve is 1.00mm, and the aperture of the second layer of sieve is 0.71mm; stones, dust, imperfect grains and shells and other sundries are screened out, and...

Embodiment 2

[0075] Prepare materials according to mass: 18 parts sandy rice flour, 16 parts soybean protein isolate powder, 15 parts whey protein powder, 5 parts inulin powder, 2 parts barley flour, 1.5 parts red bean powder, 5 parts fried white kidney bean powder, 4 parts konjac powder , 2 parts wolfberry powder, 4 parts cistanche powder, 5 parts oats, 8 parts quinoa powder, 2 parts corn grits, 2 parts perilla seed powder, 2 parts pumpkin seeds, 0.3 parts sesame.

[0076] Its preparation includes the following steps:

[0077] Raw material pretreatment: select sand rice, barley, red bean, quinoa, corn grits, wolfberry, cistanche, and oats to remove stones, sand and imperfect grains, and put sand rice into the grain cleaning machine for screening: The aperture of the first layer of sieve is 1.00mm, and the aperture of the second layer of sieve is 0.71mm; stones, dust, imperfect grains and shells and other sundries are screened out, and the oily fruit in it is removed from wolfberry.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com