Alternating-current driving type quantum dot light-emitting diode and preparation method thereof

A quantum dot light-emitting and AC-driven technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of reduced light-emitting performance of quantum dot light-emitting diodes, and achieve improved light-emitting performance, sufficient recombination, and increased transmission density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] For the second solution proposed by the present invention, see figure 2 , is a process flow chart of an embodiment of the method for preparing an AC-driven quantum dot light-emitting diode in the present invention. The preparation method of the AC-driven quantum dot light-emitting diode in the present invention, the preparation method is used to prepare the AC-driven quantum dot light-emitting diode in the aforementioned first solution, and the steps include:

[0027] S1: Anode substrate pretreatment. In this step, the anode substrate is preferably one or more of ITO conductive glass, FTO conductive glass, ITO-PET or FTO-PET, and the anode substrate is ultrasonically cleaned with acetone, deionized water and absolute ethanol in sequence and dried for later use , and UV-ozone treatment is performed before the dielectric layer is deposited.

[0028]S2: Depositing a dielectric layer on the anode substrate. In this step, the material used for the dielectric layer is pre...

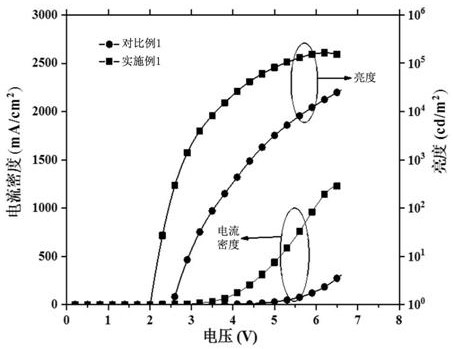

Embodiment 1

[0034] The specific steps for preparing an AC-driven quantum dot light-emitting diode in this embodiment are as follows:

[0035] (1) Select the ITO substrate as the anode substrate, ultrasonically clean the ITO substrate with acetone, deionized water and absolute ethanol, dry it and place it in a clean environment for use, and perform UV-ozone treatment before depositing the hole injection layer.

[0036] (2) Immediately after the UV-ozone treatment, PEDOT:PSS (PEDOT is a polymer of 3,4-ethylenedioxythiophene monomer, and PSS is polystyrene sulfonate) was mixed with a homogenizer at 5000 rpm Spin coating at a rotational speed for 30 seconds to form a film, and then perform annealing at a temperature of 150° C. for 10 minutes to form a hole injection layer.

[0037] (3) Take TFB (TFB is 1,2,4,5-tetrakis(trifluoromethyl)benzene) as the solute and chlorobenzene as the solvent, mix to obtain a 10mg / mL TFB solution, and then use a homogenizer at 3000 Spin coating at a speed of rp...

Embodiment 2

[0042] The specific steps for preparing an AC-driven quantum dot light-emitting diode in this embodiment are as follows:

[0043] (1) Select the ITO substrate as the anode substrate, ultrasonically clean the ITO substrate with acetone, deionized water and absolute ethanol, dry it and place it in a clean environment for use, and perform UV-ozone treatment before depositing the hole injection layer.

[0044] (2) Using P(VDF-TrFE-CFE) as the solute and dimethylformamide as the solvent, mix to obtain a mixed solution with a concentration of 100mg / mL, use a homogenizer to spin coat at a speed of 1500 rpm for 30s to form a film, and then Anneal at 100° C. for 30 minutes to form a dielectric layer.

[0045] (3) PEDOT:PSS was spin-coated at 5000 rpm for 30s to form a film, and then annealed at 150°C for 10 minutes to form a hole injection layer.

[0046] (4) Using TFB as the solute and chlorobenzene as the solvent, mix to obtain a 10 mg / mL TFB solution, then use a homogenizer to spin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com