Up-conversion red luminescent powder and preparation method thereof

A technology of red luminescence and preparation steps, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of adverse effects of use, reduced conversion luminescence performance, unstable luminescence performance, etc., and achieves low cost, improved luminescence performance, chemical Good performance and mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

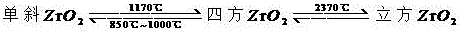

Image

Examples

Embodiment 1

[0033] ZrCa 0.06 Yb 0.075 Er 0.015 o 2.195 The preparation method of up-conversion red luminescent powder CSR(6)-I' comprises the steps:

[0034] a) Weigh 7.88g Yb respectively 2 o 3 , 0.382g Er 2 o 3 were added to two beakers with a capacity of 200mL, and 50mL of deionized water were added, according to Er 2 o 3 , Yb 2 o 3 , and the concentrated nitric acid molar ratio is 1:7, respectively measure the concentrated nitric acid and join in the beaker with the corresponding Er 2 o 3 , Yb 2 o 3 Mix and stir while performing a water bath at 70 to 80°C. After the above two rare earth oxides were completely dissolved in dilute nitric acid, the corresponding Yb(NO 3 ) 3 solution and Er(NO 3 ) 3 solution, add deionized water to the two solutions respectively to make the total volume of each solution become 200mL, at this time Yb(NO 3 ) 3 The molar concentration is 0.2mol / L, Er(NO3 ) 3 The concentration is 0.01mol / L.

[0035] b) Weigh 2.33g ZrO(NO 3 ) 2 In a 10...

Embodiment 2

[0043] ZrCa 0.06 Yb 0.075 Er 0.01 o 2.1875 The preparation method of the up-conversion red luminescent powder CSR(6)-II' comprises the following steps:

[0044] a) Weigh 7.88g Yb respectively 2 o 3 , 0.382g Er 2 o 3 were added to two beakers with a capacity of 200mL, and 50mL of deionized water were added, according to Er 2 o 3 , Yb 2 o 3 , and the concentrated nitric acid molar ratio is 1:7, respectively measure the concentrated nitric acid and join in the beaker with the corresponding Er 2 o 3 , Yb 2 o 3 Mix and stir while performing a water bath at 70 to 80°C. After the above two rare earth oxides were completely dissolved in dilute nitric acid, the corresponding Yb(NO 3 ) 3 solution and Er(NO 3 ) 3 solution, add deionized water to the two solutions respectively to make the total volume of each solution become 200mL, at this time Yb(NO 3 ) 3 The molar concentration is 0.2mol / L, Er(NO 3 ) 3 The concentration is 0.01mol / L.

[0045] b) Weigh 2.33g ZrO(N...

Embodiment 3

[0053] ZrCa 0.06 Yb 0.075 Er 0.012 o 2.1905 The preparation method of up-conversion red luminescent powder CSR (6)-Ⅲ comprises the following steps:

[0054] b) Weigh 2.33g ZrO(NO 3 ) 2 In a 100mL beaker, measure 0.2mol / L concentration of Yb(NO 3 ) 3 Solution 3.75mL, 0.01mol / L Er(NO 3 ) 3 Add 10.0mL of the solution into the beaker, then weigh 0.1416g Ca(NO 3 ) 2 • 4H 2 O in a beaker, the total volume of supplemented liquid is 50mL, and the solution becomes completely clear after rapid stirring with a magnetic stirrer. At this time, Zr 4+ The concentration is 0.2mol / L.

[0055] Other steps are identical with above-mentioned embodiment two, can get ZrCa 0.06 Yb 0.075 Er 0.012 o 2.1905 Up-conversion red luminescent powder CSR(6)-Ⅲ. At room temperature, excited by 50mW 980nm laser, the powder can produce bright red light visible to the naked eye under bright field.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com