Novel preparation method of functionalized porous magnetic microspheres

A technology of magnetic microspheres and porous microspheres, applied in the direction of coating, can solve the problems of uneven surface hydrophilicity and hydrophobicity, few functional groups, etc., to achieve rich surface functional groups, increased surface area, and uniform particle size distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of seed microspheres. In this example, polystyrene microspheres were prepared by soap-free emulsion polymerization. The specific synthesis method is as follows:

[0030] 1) Add 500mL deionized water and 50mL styrene to a 1L three-necked flask, and stir for 10 minutes at room temperature under nitrogen gas at a speed of 200rpm;

[0031] 2) Add 1.0g of potassium persulfate to 50mL of deionized water, and ultrasonically dissolve;

[0032] 3) Pour the potassium persulfate solution into (1), raise the temperature to 80°C, and stir at 200rpm for 24 hours.

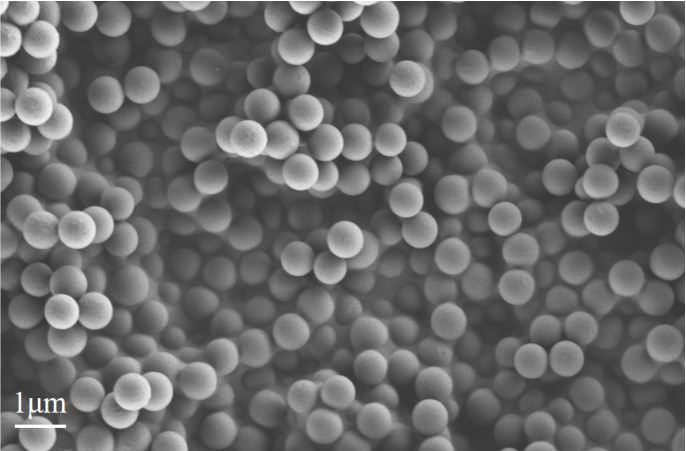

[0033] The scanning electron microscope images of the prepared styrene seed microspheres are as follows: figure 1 As shown, the particle size of the seed microspheres is 700 nm.

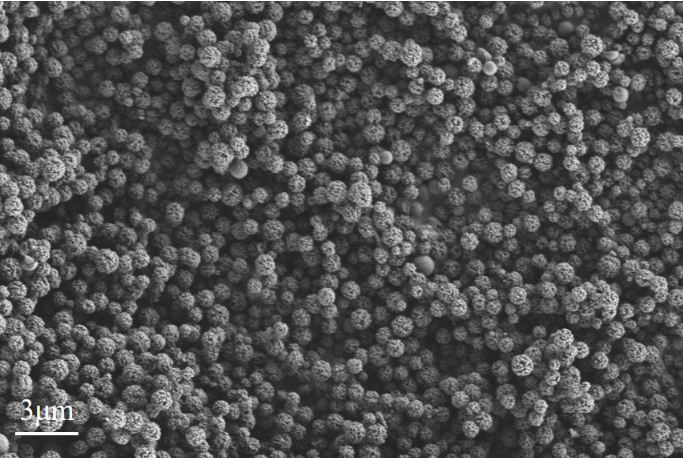

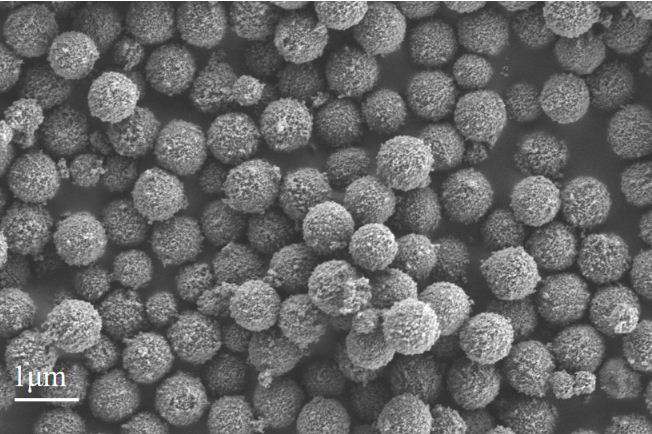

[0034] (2) Preparation of porous microspheres. In this example, glycidyl methacrylate was used as a functional monomer, cyclohexanol was used as a porogen, SDS was used as an emulsifier, PVP-K30 was used as a stabilizer, and BP...

Embodiment 2

[0047] (1) Preparation of seed microspheres. In this example, polyglycidyl methacrylate microspheres were prepared by soap-free emulsion polymerization. The specific synthesis method is as follows:

[0048] 1) Add 600mL deionized water and 30mL glycidyl methacrylate into a 1L three-necked flask, stir at room temperature for 10 minutes under nitrogen gas, and rotate at 200rpm;

[0049] 2) Add 0.8g of potassium persulfate to 36mL of deionized water, and ultrasonically dissolve;

[0050] 3) Pour the potassium persulfate solution into (1), raise the temperature to 75°C, and stir at 200rpm for 24 hours.

[0051] (2) Preparation of porous microspheres. In this example, methyl acrylate was used as a functional monomer, n-octanol was used as a porogen, SDS was used as an emulsifier, PVP-K30 was used as a stabilizer, and AIBN was used as an initiator , to prepare porous microspheres, the specific method is as follows:

[0052] 1) Weigh 2gSDS, 1.2gPVP-K30 in water, configure 200mL so...

Embodiment 3

[0064] (1) Preparation of seed microspheres. In this example, polystyrene microspheres were prepared by soap-free emulsion polymerization. The specific synthesis method is as follows:

[0065] 1) Add 500mL deionized water and 50mL styrene to a 1L three-necked flask, and stir for 10 minutes at room temperature under nitrogen gas at a speed of 200rpm;

[0066] 2) Add 1.0g of potassium persulfate to 50mL of deionized water, and ultrasonically dissolve;

[0067] 3) Pour the potassium persulfate solution into (1), raise the temperature to 80°C, and stir at 200rpm for 24 hours.

[0068] (2) Preparation of porous microspheres. In this example, glycidyl methacrylate was used as a functional monomer, cyclohexanol was used as a porogen, SDS was used as an emulsifier, PVP-K30 was used as a stabilizer, and BPO For initiator, prepare porous microsphere, concrete method is as follows:

[0069] 1) Weigh 0.23gSDS, 2gPVP-K30 in water, prepare 200mL solution, stir to dissolve, and it is solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com