A kind of single crystal material precursor and compound oxide powder and its preparation method and application

A technology of single crystal materials and precursors, applied in the field of materials, can solve the problems of environmental burden and high DCR of lithium-ion batteries, and achieve an environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

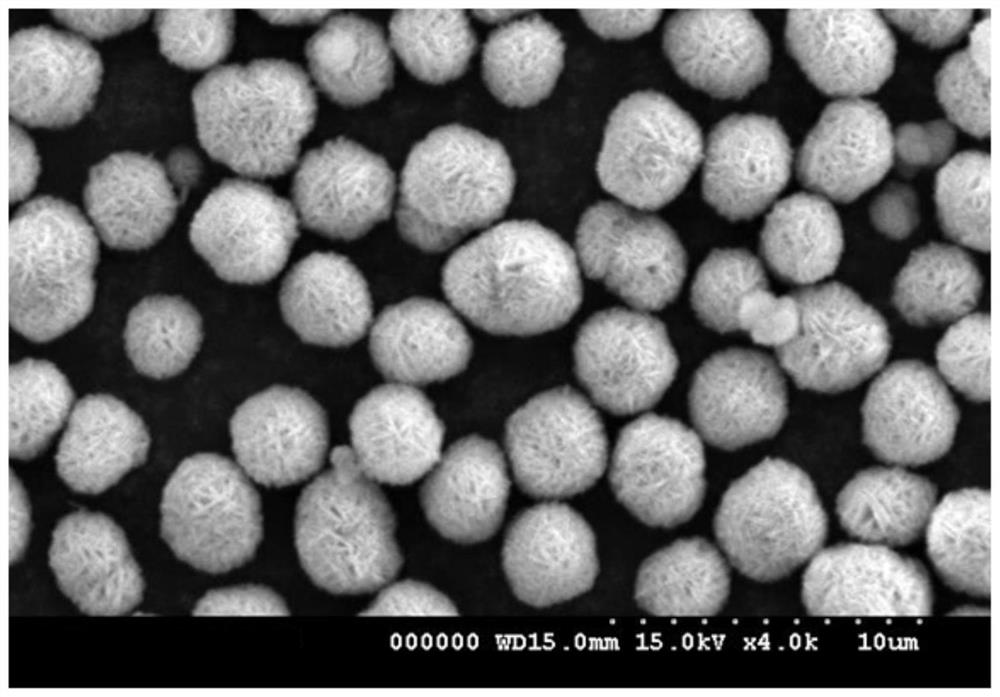

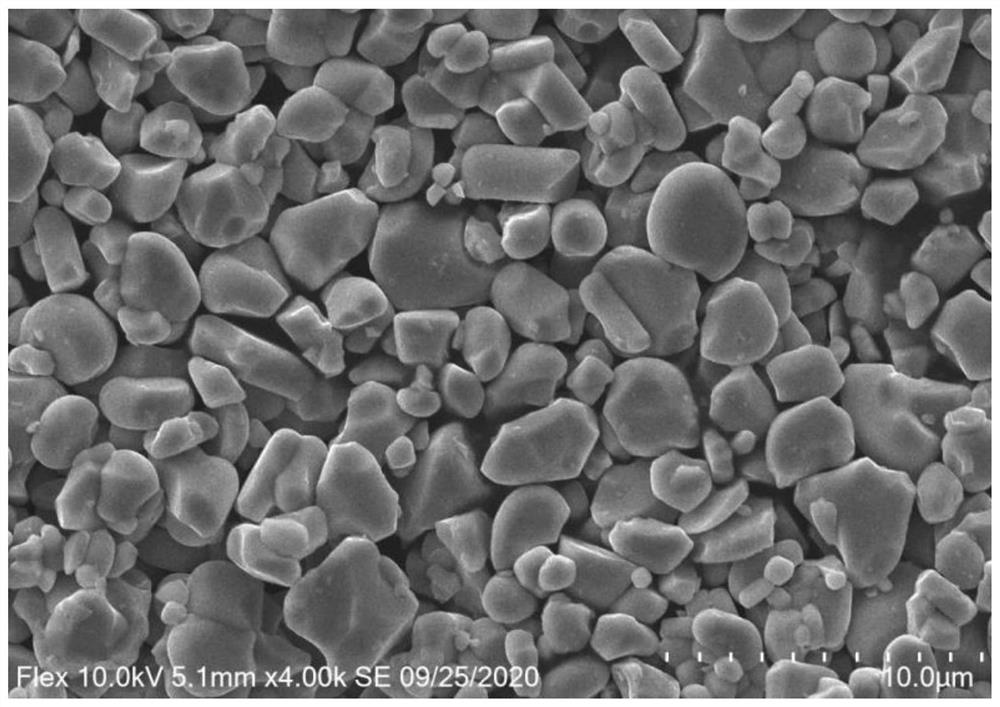

Image

Examples

Embodiment 1

[0034] S1, the metal mixture (Ni, Co, Mn, Al four kinds of metals are mixed in molar ratio of 1:1:1:0.01), nitric acid, high-purity water according to the molar ratio of 10:1:1 and simultaneously add the pre-added concentration of 50g 2g / L of ammonium sulfate was added to the reactor of sodium chloride aqueous solution of / L at the same time. Under normal pressure conditions, the ORP value of redox potential was controlled at -1000mv, the conductivity was controlled at 20000uS / cm, and the concentration of complexing agent was controlled at -1000mv. Controlled at 15g / L, stirring input power controlled at 3.5kw / m 3 h, the metal ion concentration is controlled at 30g / L, the pH value is controlled at 8.5, and the reaction temperature is controlled at 60°C for chemical corrosion and crystallization reaction for 40h, the particle size d50 grows to 1μm, and then passes through at a rate of 10L / h. Enter the oxidant air, control the redox potential at -800mv, use a spectrometer to moni...

Embodiment 2

[0038] S1, the metal mixture (the five metals of Ni, Co, Mn, Al, Zr are mixed in a molar ratio of 7:1:3:0.006:0.003), nitric acid, and high-purity water are added in parallel according to the molar ratio of 10:1:2. In the reactor of the sodium chloride aqueous solution with a good concentration of 40g / L, 30g / L of ammonium sulfate was added at the same time. The concentration of complexing agent is controlled at 50g / L, and the stirring input power is controlled at 3.0kw / m 3 h, the metal ion concentration is controlled at 35g / L, the pH value is controlled at 9.0, and the reaction temperature is controlled at 60°C for 24h chemical corrosion crystallization reaction, the particle size d50 grows to 1.5μm, and then at a rate of 30L / h The oxidant air was introduced, the ORP value of the redox potential was controlled at -400mv, and the color of the material was monitored by a color spectrometer. The material continued to stay in the reactor for 80h, and the crystallization process co...

Embodiment 3

[0042]S1, the metal mixture (Ni, Co, Mn, Mg five kinds of metals are mixed in molar ratio 6:2:2:0.002), nitric acid, high-purity water according to the molar ratio of 10:1:1.5 and simultaneously add the pre-added concentration of 90g 10g / L of ammonium sulfate was added to the reactor of sodium sulfate aqueous solution at the same time. Under normal pressure conditions, the ORP value of the redox potential was controlled at -500mv, the conductivity was controlled at 1000uS / cm, and the concentration of the complexing agent was controlled at At 30g / L, the stirring input power is controlled at 3.0kw / m 3 h, the metal ion concentration is controlled at 35g / L, the pH value is controlled at 9.0, and the reaction temperature is controlled at 60°C for chemical corrosion and crystallization reaction for 48h, the particle size d50 grows to 2μm, and then passes through at a rate of 30L / h. Enter the oxidant air, control the ORP value of the redox potential at 0mv, use a spectrometer to moni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com