Folding and forming coil, power inductor using the same, and inductance processing method

A technology for forming coils and power inductors, applied in inductors, fixed inductors, fixed signal inductors, etc., can solve the problems that the processing effect is difficult to achieve expectations, the coil pin part is difficult to be flattened, and the cost is high, and the volume And the effect of occupied space compression, various implementation methods, and low difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

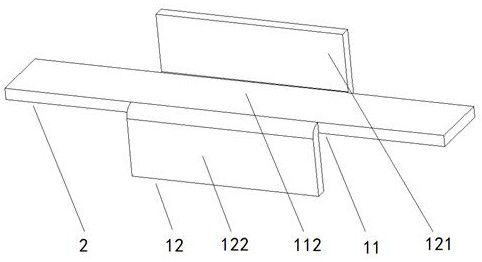

[0058] like Figure 1~Figure 3 As shown, a power inductor is produced by using the above-mentioned folded and formed coil. The power inductor is a horizontal structure and includes an inductance magnet 3 and at least one folded and formed coil disposed inside the inductance magnet 3 . The utility portion 1 of the folded and formed coil includes a first connection segment 111 , a second connection segment 112 and a third connection segment 113 which are connected to each other. Wherein, the first connecting section 111 and the second connecting section 112, the second connecting section 112 and the third connecting section 113 are perpendicular to each other, and the first connecting section 111 and the third connecting section 113 The two are parallel and both are connected to the lead portion 2 of the folded and formed coil, the second connecting section 112 is buried inside the inductance magnet 3, and the edges on both sides of the second connecting section 112 are respecti...

Embodiment 2

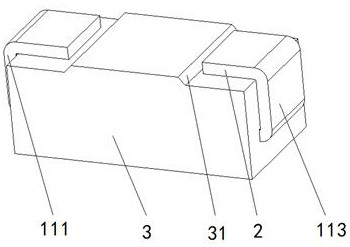

[0060] like Figure 4~Figure 6 As shown in the figure, a power inductor is also made of the above-mentioned folded and formed coil. The power inductor is a vertical structure and includes an inductance magnet 3 and at least one folded and formed coil disposed inside the inductance magnet 3 . The utility portion 1 of the folded and formed coil is buried inside the induction magnet 3 , and the utility portion 1 includes a first connection segment 111 , a second connection segment 112 and a third connection segment 113 which are connected to each other. Wherein, the first connecting section 111 and the second connecting section 112, the second connecting section 112 and the third connecting section 113 are perpendicular to each other, and the first connecting section 111 and the third connecting section 113 The two are parallel and connected to the pin part 2 of the folding forming coil, and the first and second folding The widths of both the first folding section 121 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com