Nanorod array coating with thermal control immunity and antioxidant functions as well as preparation method and application of nanorod array coating

A nanorod and anti-oxidation technology, which is applied in coatings, surface reaction electrolytic coatings, electrolytic coatings, etc., can solve problems such as inapplicability to clinical applications, lack of immune modulation ability, and lack of anti-oxidation functions, and achieve dip coating The effect of simple coating method, stable process and strong oxidation self-polymerization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

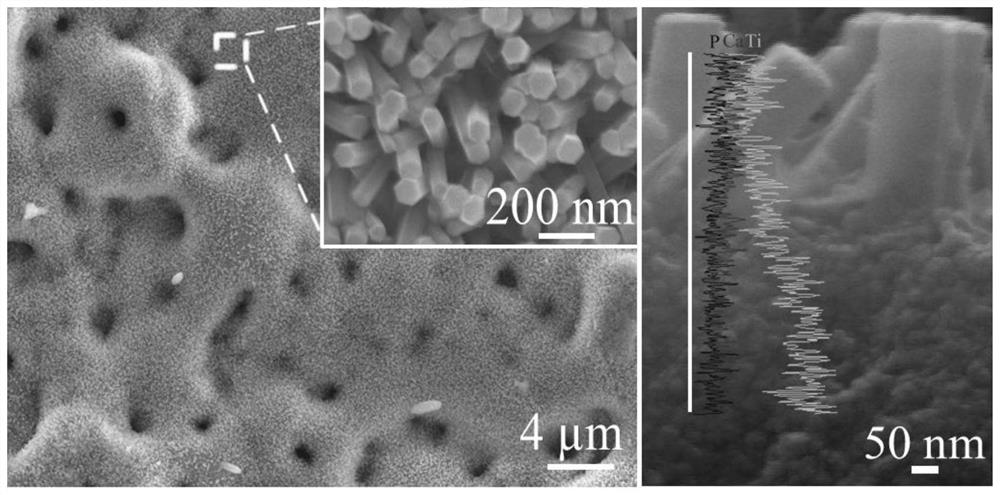

Embodiment 1

[0037] A method for preparing a nanorod arrayed coating with functions of thermal control immunity and anti-oxidation, comprising the following steps:

[0038]Step 1. Perform micro-arc oxidation. The parameters of the micro-arc oxidation are set as follows: set the arc frequency of the micro-arc oxidation to 100 Hz, the power supply to a positive voltage of 400 V, and the duty cycle to 7.5%. In the micro-arc oxidation process, titanium or its alloy disc is used as the anode, and the stainless steel electrolytic cell is used as the cathode. The composition and concentration of the electrolyte are: sodium hydroxide (NaOH) 0.005mol / L, calcium acetate (Ca(CH 3 COO) 2 ) 0.22mol / L, β-glyceride phosphate disodium salt pentahydrate (β-GP) 0.02mol / L. During the preparation process, a cooling system is used to control the temperature of the micro-arc oxidation electrolyte to 303K. After micro-arc oxidation, the sample coated with titanium dioxide coating was obtained, and the prepared...

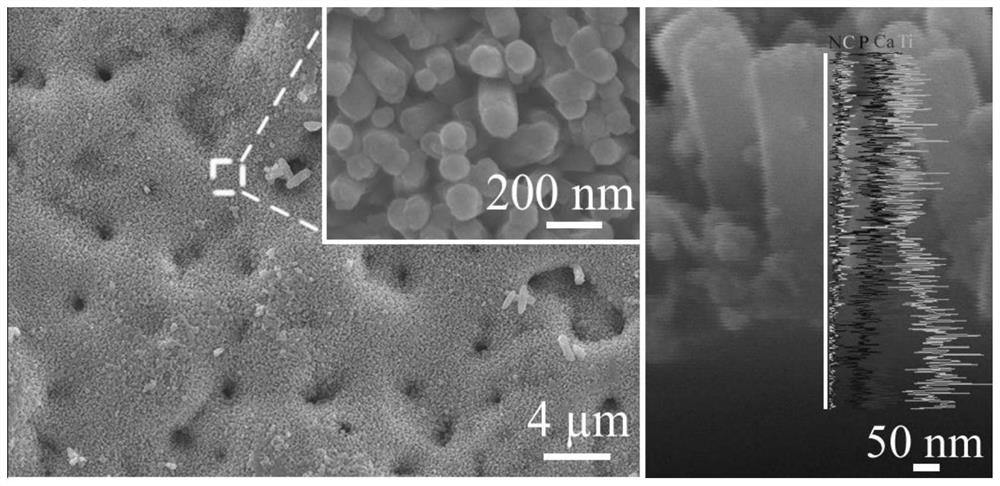

Embodiment 2

[0047] A method for preparing a nanorod arrayed coating with functions of thermal control immunity and anti-oxidation, comprising the following steps:

[0048] Step 1. Perform micro-arc oxidation. The parameters of the micro-arc oxidation are set as follows: set the arc frequency of the micro-arc oxidation to 100 Hz, the power supply to a positive voltage of 400 V, and the duty cycle to 7.5%. In the micro-arc oxidation process, titanium or its alloy disc is used as the anode, and the stainless steel electrolytic cell is used as the cathode. The composition and concentration of the electrolyte are: sodium hydroxide (NaOH) 0.005mol / L, calcium acetate (Ca(CH 3 COO) 2 ) 0.22mol / L, β-glyceride phosphate disodium salt pentahydrate (β-GP) 0.02mol / L. During the preparation process, a cooling system is used to control the temperature of the micro-arc oxidation electrolyte to 303K. After micro-arc oxidation, the sample coated with titanium dioxide coating was obtained, and the prepare...

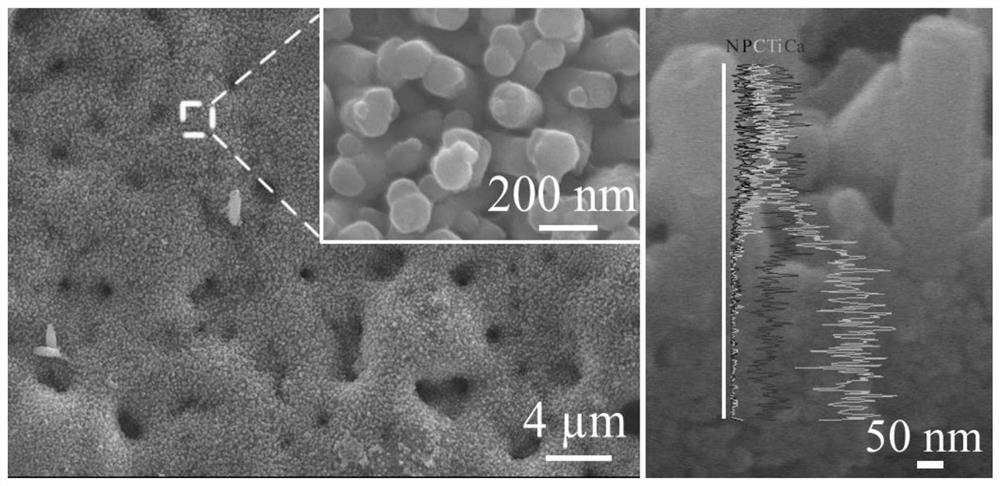

Embodiment 3

[0057] A method for preparing a nanorod arrayed coating with functions of thermal control immunity and anti-oxidation, comprising the following steps:

[0058] Step 1. Perform micro-arc oxidation. The parameters of the micro-arc oxidation are set as follows: set the arc frequency of the micro-arc oxidation to 100 Hz, the power supply to a positive voltage of 400 V, and the duty cycle to 7.5%. In the micro-arc oxidation process, titanium or its alloy disc is used as the anode, and the stainless steel electrolytic cell is used as the cathode. The composition and concentration of the electrolyte are: sodium hydroxide (NaOH) 0.005mol / L, calcium acetate (Ca(CH 3 COO) 2 ) 0.22mol / L, β-glyceride phosphate disodium salt pentahydrate (β-GP) 0.02mol / L. During the preparation process, a cooling system is used to control the temperature of the micro-arc oxidation electrolyte to 303K. After micro-arc oxidation, the sample coated with titanium dioxide coating was obtained, and the prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com