Rapid heat diffusion heating pipeline based on power surrounding technology

A heating and heat technology, applied in the direction of engine lubrication, hot water central heating system, pipe components, etc., can solve the problems of slow temperature rise and decrease of heating efficiency in the user's residential area, so as to improve air flow, improve air freshness, The effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

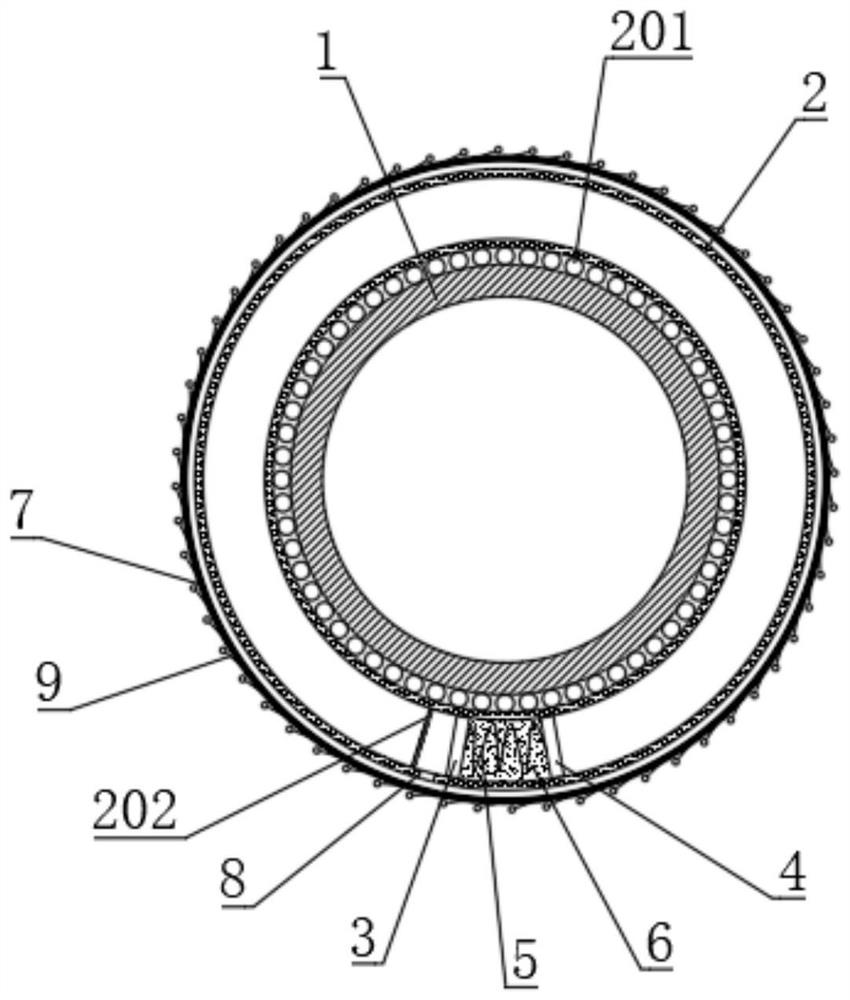

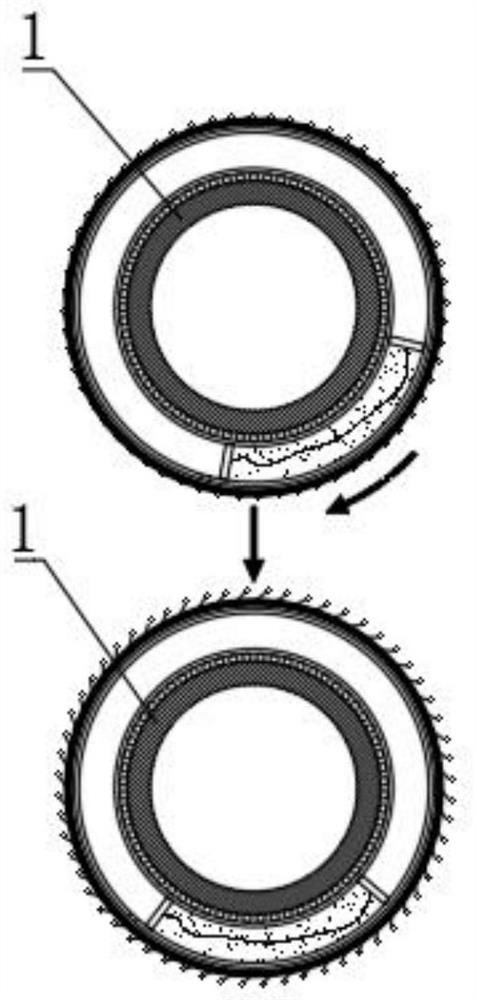

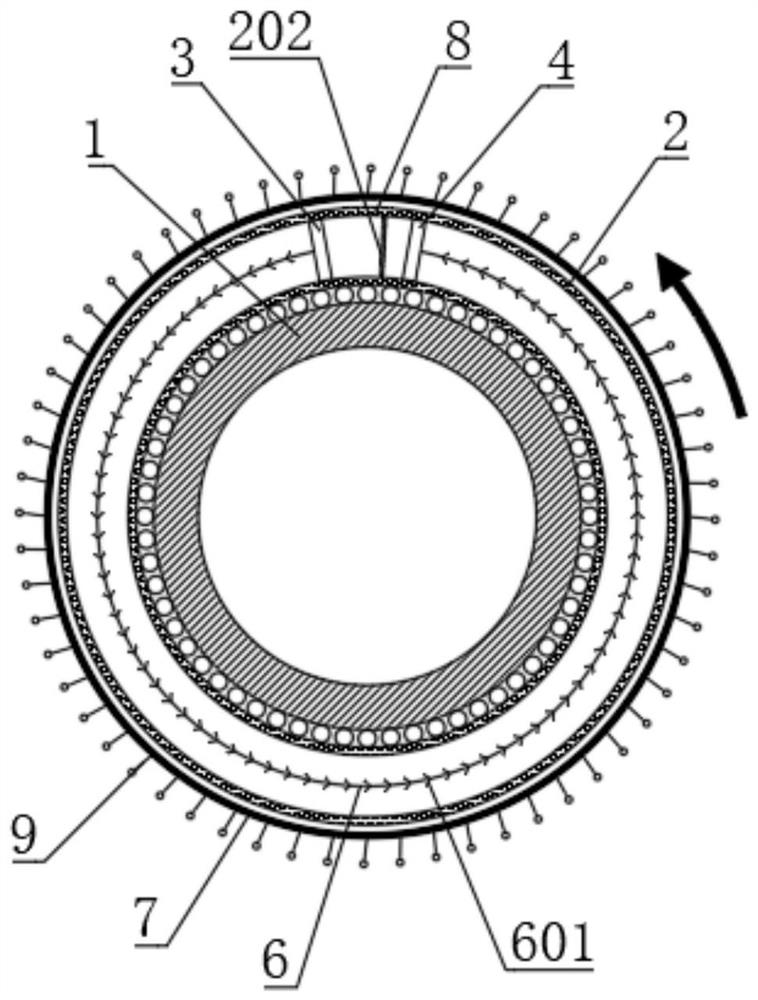

[0044] see Figure 1-3 , a heating pipe for rapid heat diffusion based on power surround technology, comprising a heating transmission pipe 1, the outer end of the heating transmission pipe 1 is rotatably connected to a power swivel 2, the inner wall of the power swivel 2 is fixedly connected to a fixed sealing disc 3, and the power swivel The ring 2 is slidingly connected with a dynamic sealing disc 4 located on the right side of the fixed sealing disc 3, ammonium chloride powder 5 is filled between the fixed sealing disc 3 and the dynamic sealing disc 4, and the fixed sealing disc 3 and the dynamic sealing The thermally variable metal rope 6 is fixedly connected between the discs 4, the outer end of the power swivel 2 is fixedly connected with an outsourcing annular capsule 7, and the outer end of the power swivel 2 is dug with a release hole 8, which is located in a fixed and closed circle. On the left side of piece 3, the outer end of the outsourcing annular capsule piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com